| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10083965

Manufacturer Communication Number: A13-082

Summary

SERVICE BULLETIN – THE PISTON RINGS ON CERTAIN CYLINDERS MAY ROTATE AND ALIGN WHICH CAN LEAD TO SPARK PLUG FOULING. SPARK PLUG FOULING MAY REUSLT IN ROUGH ENGINE IDLE AND/OR ENGINE MISFIRE.

A13-082

May 18, 2015

51869-02164 Version 7

Warranty Extension: MIL Comes On With DTCs P0301 thru P0304

Supersedes 13-082, dated September 12, 2015, to revise the information highlighted in yellow.

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2009–13 | Pilot | ALL | Check the iN VIN Status for Eligibility |

REVISON SUMMARY

- Under REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT, Replace Parts as Needed for Repair Procedure B, changed bolt count for the 12 x 163 Washer bolt (P/N 90005-PAA-A01) under Cyl 1-4 from 8 to 16. Also changed the bolt count for Connecting Rod Bolt from 8 to 6.

CORRECTIVE ACTION

2009–11 Models: Complete the diagnosis procedure and if necessary, update the PCM software and replace the affected spark plugs. If the vehicle returns after the updated PCM software and spark plug replacement have been installed, clean the pistons and replace the pistons rings along with the spark plugs (Procedure B).

NOTE: Make sure the software update has been completed, spark plugs replaced (Procedure A), and the vehicle returned to the customer before making any additional repairs. Failure to do so will result in claim review by your DPSM and possible debit.

2012–13 Models: Complete the diagnosis procedure and if necessary, clean the pistons and replace the pistons rings along with the spark plugs (Procedure B).

BACKGROUND

American Honda is announcing a powertrain warranty extension as a result of a settlement of a class action captioned, Soto et al.v. American Honda

is announcing a powertrain warranty extension as a result of a settlement of a class action captioned, Soto et al.v. American Honda Motor Co., Inc., Case No. 3:12-cv-1377-SI (N.D. Cal.).

Motor Co., Inc., Case No. 3:12-cv-1377-SI (N.D. Cal.).

The piston rings on certain cylinders may rotate and align, which can lead to spark plug fouling. This can set DTCs P0301 No. 1 cylinder misfire detected, P0302 No. 2 cylinder misfire detected, P0303 No. 3 cylinder misfire detected, P0304 No. 4 cylinder misfire detected, and cause the MIL to come on.

American Honda is extending the powertrain warranty to cover repairs related to engine misfire (that triggers DTCs P0301 through P0304) to 8 years with unlimited mileage from the original date of purchase and has settled a class action based on this remedial measure.

is extending the powertrain warranty to cover repairs related to engine misfire (that triggers DTCs P0301 through P0304) to 8 years with unlimited mileage from the original date of purchase and has settled a class action based on this remedial measure.

This warranty extension does not apply to any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded or similar title under any state’s law.

CUSTOMER NOTIFICATION

Owners of affected vehicles were sent a class action settlement notice regarding this warranty extension starting in October 2013.

Before doing work on a vehicle, verify its eligibility by doing an iN VIN status inquiry.

Refer customers seeking information about settlement benefits to www.enginemisfiresettlement.com, or instruct them to call 888-888-3082.

DIAGNOSIS

- Connect the HDS and check for the following DTCs: P0301 No. 1 Cylinder Misfire Detected, P0302 No. 2 Cylinder Misfire Detected, P0303 No. 3 Cylinder Misfire Detected, P0304 No. 4 Cylinder Misfire Detected.

Are any of these DTCs stored?

YES – Go to step 2.

NO – Stop. This bulletin does not apply. Continue with normal troubleshooting.

- Remove and check the spark plug(s) on the affected cylinders (example: if P0301 is stored, check the spark plug on cylinder No. 1).

Are the spark plug(s) fouled?

YES – Go to step 3.

NO – Stop. This bulletin does not apply. Continue with normal troubleshooting.

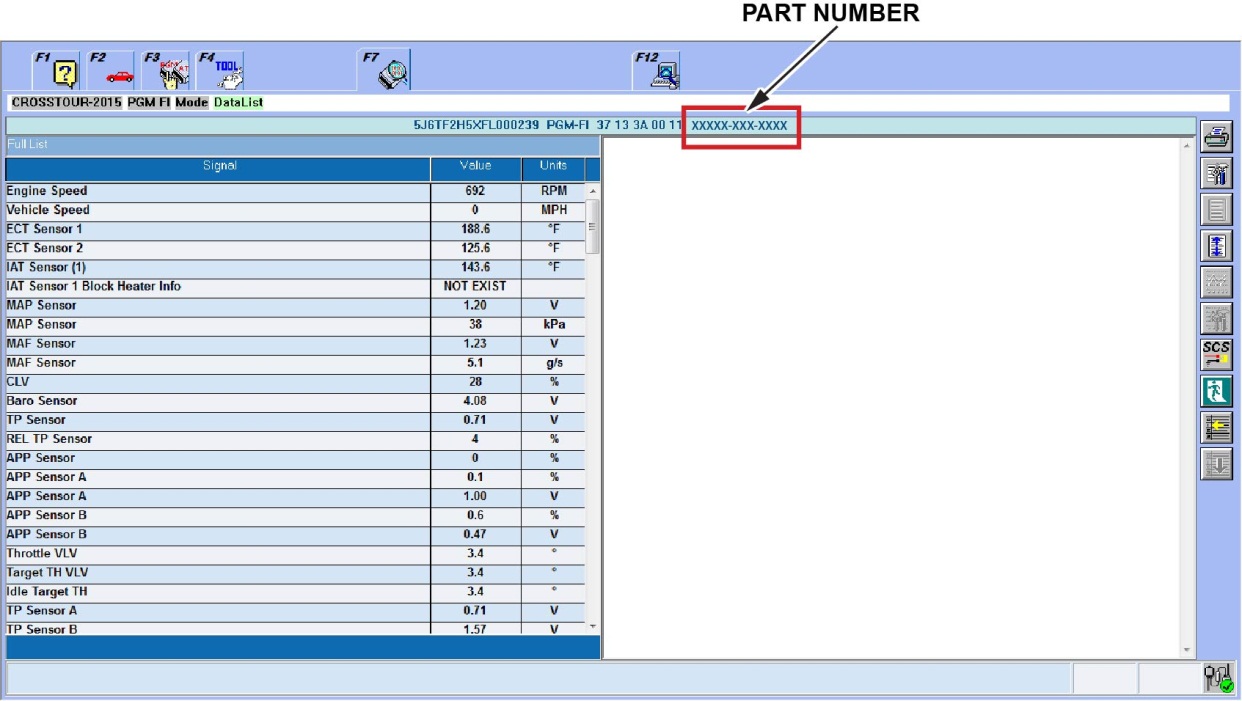

- Check the PCM software version P/N located above the PGM FI Data List. All 2012–13 vehicles are up to date, go directly to step 4.

| Year/Model | Program ID (or later) | Program P/N (or later) |

| 2009–10 Pilot (2WD) | N0A570 | 37805-RN0-A57 |

| 2009–10 Pilot (4WD) | N0A770 | 37805-RN0-A77 |

| 2011 Pilot (2WD) | N0A630 | 37805-RN0-A63 |

| 2011 Pilot (4WD) | N0A830 | 37805-RN0-A83 |

| 2012–13 Pilot (ALL) | Software Updated from Factory | |

Is the PCM Program ID and/or Program P/N the same or newer than what is listed above, 2009–11 model years only?

NO – The PCM software needs to be updated. Go to REPAIR PROCEDURE A.

YES – The correct software is installed. The piston rings on select cylinders need to be replaced. Go to step 4.

IMPORTANT NOTICE: The PCM software must first be updated with the correct version, replace spark plugs and the vehicle returned to the customer. Piston cleaning and piston ring replacement, as described below, should only be done after the customer has returned with a second failure or if the vehicle’s software is the correct version. Failure to follow this process correctly may result in a full debit of the warranty claim to your dealer.

- Note which DTCs are stored in the vehicle.

Does the vehicle have DTC P0304 stored? (Any combination of DTCs P0301, P0302, P0303, P0304 may also be stored.)

YES – Go to REPAIR PROCEDURE B for the cylinders listed, Cylinders 1–4: Clean the pistons, replace the piston rings, and replace the spark plugs.

NO – Go to REPAIR PROCEDURE B for the cylinders listed below:

- Cylinder 1–3: Clean the pistons and replace the pistons rings.

- Cylinder 1–4: Replace the spark plugs.

PARTS INFORMATION

NOTE: Do the DIAGNOSIS first to determine which cylinders you will need to repair.

REPAIR PROCEDURE A – SOFTWARE UPDATE AND CYLINDERS 1–4 SPARK PLUG REPLACEMENT

Required Parts

| Part Name | Part Number | Quantity |

| Spark Plugs (2009–11 All) | 12290-R70-A01 | 4 |

| Spark plugs (2012–13 All) | 12290-R71-L01 | 4 |

REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT Required Parts

| Part Name | Part Number | Cyl 1-3 | Cyl 1-4 |

| Cyl. Gasket (Fr Cylinder Head) | 12251-R70-A01 | 1 | |

| Cyl. Gasket (Rr Cylinder Head) | 12261-R70-A01 | 1 | 1 |

| Drain Washer 14 mm | 94109-14000 | 1 | 1 |

| EGR Pipe Gasket A | 18716-R70-A01 | 1 | 1 |

| EGR Pipe Gasket B | 18719-R70-A01 | 1 | 1 |

| Ex. Chamber Gasket | 18115-R70-A01 | 1 | 2 |

| Ex. Pipe Gasket | 18212-SA7-003 | 2 | 2 |

| Head Gasket Fr (Valve Cover) | 12030-R70-A00 | 1 | |

| Head Gasket Rr. (Valve Cover) | 12050-R70-A00 | 1 | 1 |

| In. Manifold Gasket (Intake Top Cover) | 17146-R70-A01 | 1 | 1 |

| In. Manifold Gasket (2009–10 2WD) | 17105-RCA-A01 | 1 | 1 |

| In. Manifold Gasket (2009–13 4WD & 2011–13 2WD) | 17105-RCJ-A01 | 1 | 1 |

| Oil Filter | 15400-PLM-A02 | 1 | 1 |

| O-ring (7.47 mm x 3.6 mm) | 91301-PLC-000 | 2 | 2 |

| O-ring (31.2 mm x 4.1 mm) | 91314-PH7-003 | 2 | 2 |

| Piston Ring Set | 13011-5G0-A02 | 3 | 4 |

| Pre-chamber Gasket | 18393-SDB-A00 | 1 | 1 |

| Self-locking Nut (8 mm) | 90212-RCA-A01 | 4 | 8 |

| Self-locking Nut (10 mm) | 90212–SA5-003 | 9 | 9 |

| Spark Plug (2009–11 All) | 12290-R70-A01 | 4 | 4 |

| Spark plug (2012–13 All) | 12290-R71-L01 | 4 | 4 |

| Strainer O-ring | 15221-RYE-A01 | 1 | 1 |

| Timing Belt Bolt | 14551-RCA-A01 | 1 | 1 |

| Water Gasket Fr. | 19411-P8A-A03 | 1 | 1 |

| Water Gasket Rr. | 19412–P8A-A02 | 1 | 1 |

Replaced Parts as Needed for Repair Procedure B

| Part Name | Part Number | Cyl 1-3 | Cyl 1-4 |

| Connecting Rod Bolt (May require Up to 6 bolts per cylinder head) | 13204–P8A–A01 | 6 | 8 |

| Washer-Bolt (12 x 163) (May require up to 8 bolts per cylinder head) | 90005–PAA–A01 | 8 | 16 |

REQUIRED MATERIALS – REPAIR PROCEDURE B

| Material Description | Part Number | Quantity |

Honda Long-Life Antifreeze/Coolant Type 2 Long-Life Antifreeze/Coolant Type 2 | OL999–9011 | 3 gallons |

Genuine Honda Motor Oil 0W–20 Motor Oil 0W–20 | 08798–9036 | 6 quarts |

Genuine Honda Motor Oil 5W–20 (if requested) (2009-11) Motor Oil 5W–20 (if requested) (2009-11) | 08798–9032 | 6 quarts |

| Hondabond HT (1 Tube Repairs 5 Vehicles) | 08718–0004 | 1 tube |

Genuine Honda Throttle Plate Cleaner Throttle Plate Cleaner | 08700–9204 | |

| Nylon Parts Cleaning Brush | (commercially available) | |

| 5/16 ID Flexible Hose | (commercially available) |

TOOL INFORMATION – REPAIR PROCEDURE B

| Tool Description | Tool Number | Quantity |

| Piston Ring Groove Cleaner | 07AAZ–TA5A100 | 1 |

REPAIR PROCEDURE A – SOFTWARE UDPATE AND CYLINDERS 1–4 SPARK PLUG REPLACEMENT

- For 2009–11 models only, update the PCM software. Refer to Service Bulletin 01-023, Updating Control Units/Modules.

- Replace spark plugs on cylinders 1–4, then return the vehicle to the customer.

REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT

2009–11 Models: Confirm PCM software is or has been updated with the correct version, spark plugs 1–4 have been replaced and the vehicle returned to the customer (Procedure A). Piston cleaning and piston ring replacement along with the spark plugs should only be done after customer has returned with a second failure or if the vehicles software is the correct version (Procedure B). Failure to follow this process correctly may result in a full debit of the warranty claim to your dealer.

2012–13 Models: Are equipped with updated software from the factory, no software update is needed. Piston cleaning and piston ring replacement along with the spark plugs should only be done after the diagnosis of the spark plugs has concluded that (Procedure B) is required.

The following service manual procedures have been used in full or in part within this service bulletin. For more detail on these procedures, and torque specifications for some components, refer to the appropriate electronic service manual.

- Battery Terminal Disconnection and Reconnection

- Fuel Pressure Relieving

- Fuel Line/Quick-Connect Fitting Removal

- Air Cleaner Removal/Installation

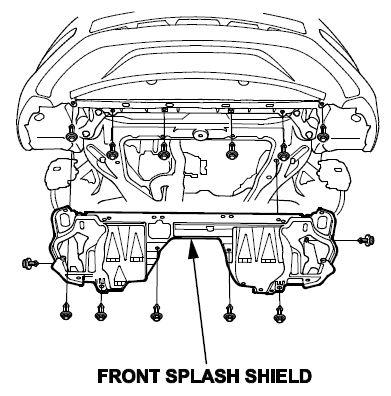

- Splash Shield Replacement

- Drive Belt Removal/Installation

- Engine Oil Replacement

- Coolant Replacement

- Hydraulic Power Steering Fluid Check/Replacement

- Intake Manifold Removal and Installation

- Timing Belt Removal and Installation

- Warm Up-TWC Removal/Installation

- Cylinder Head Cover Removal

- Cylinder Head Removal and Installation

- Piston Ring Replacement

- PCM Idle Learn Procedure

- Valve Adjustment

Piston Removal Procedure

- Use fender covers to avoid damaging painted surfaces.

- To avoid damaging any wires and terminals, unplug the circuit connectors carefully while holding the connector portion.

- Mark all the circuits and hoses to avoid misconnection. Make sure they do not contact other circuit wiring, hoses, or interfere with other parts.

- Relieve the fuel pressure.

- Remove both front wheels so you can fully lower the vehicle.

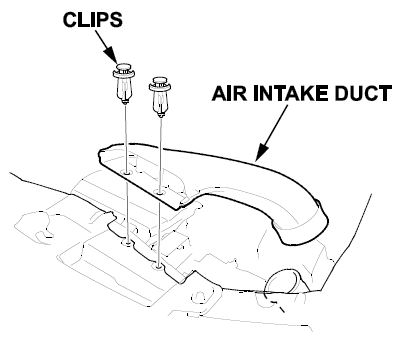

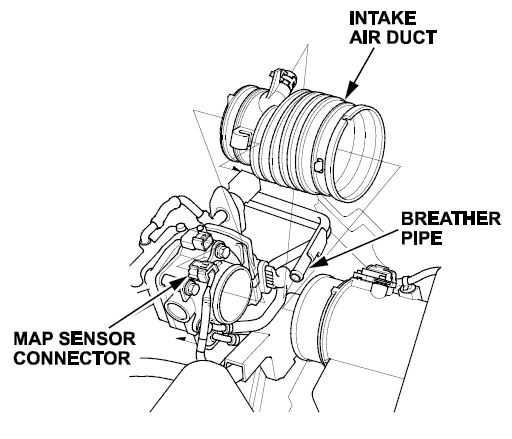

- Remove the intake duct.

- Do the battery removal procedure.

- Disconnect the fuel feed hose line at the bulkhead.

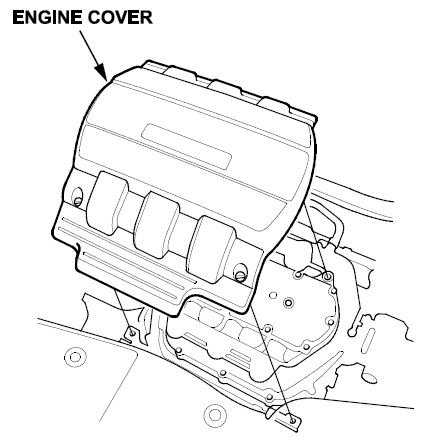

- Remove the engine cover.

- Remove the radiator cap.

- Raise the vehicle.

- Remove the front splash shield.

- Drain the engine oil.

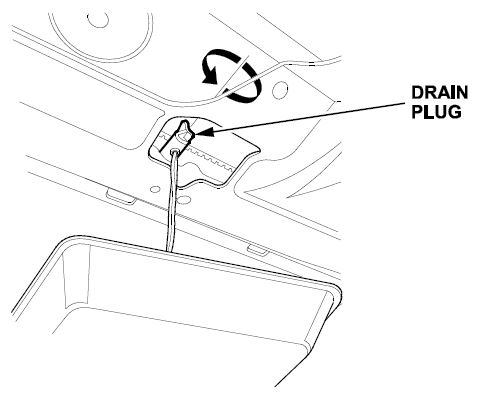

- Loosen the drain plug on the radiator, and drain the coolant.

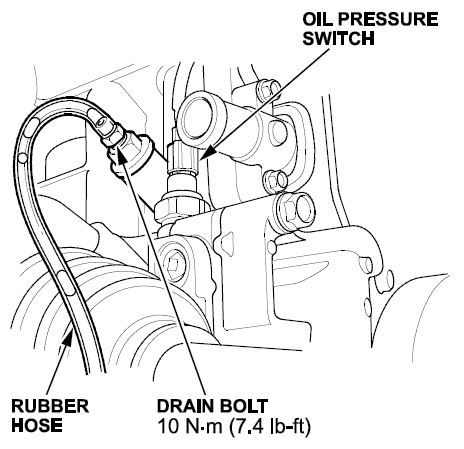

- Install a 5/16th inner diameter rubber hose on the drain bolt at the rear of the engine block, loosen the drain bolt, and drain all remaining coolant. Then disconnect the oil pressure switch connector.

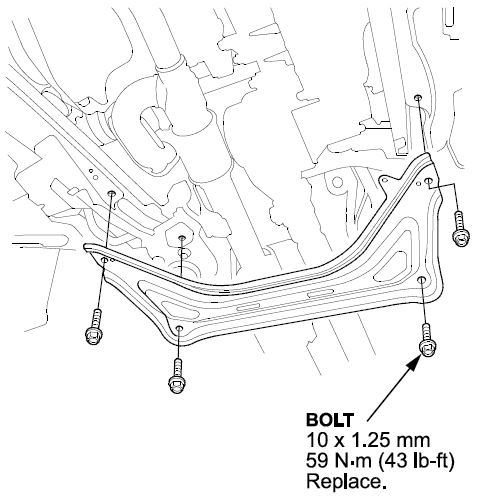

- Remove the subframe stiffener.

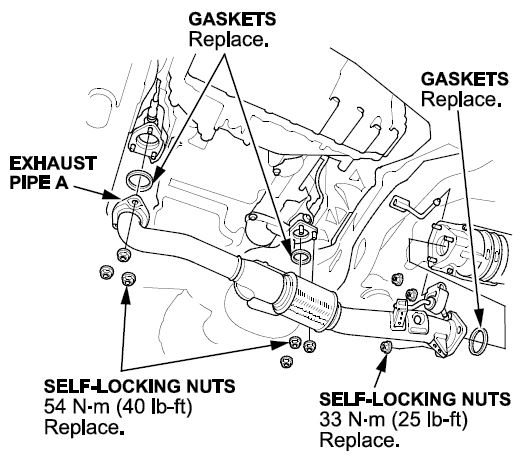

- Remove exhaust pipe A.

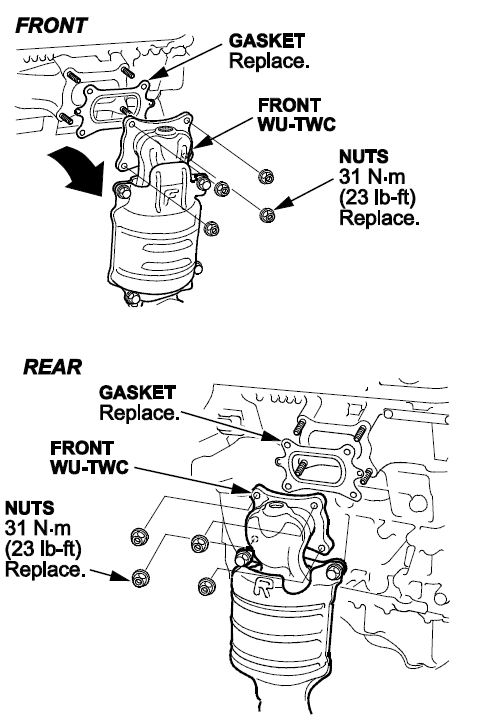

- Depending on the diagnosis, remove the appropriate WU-TWC support bracket bolts.

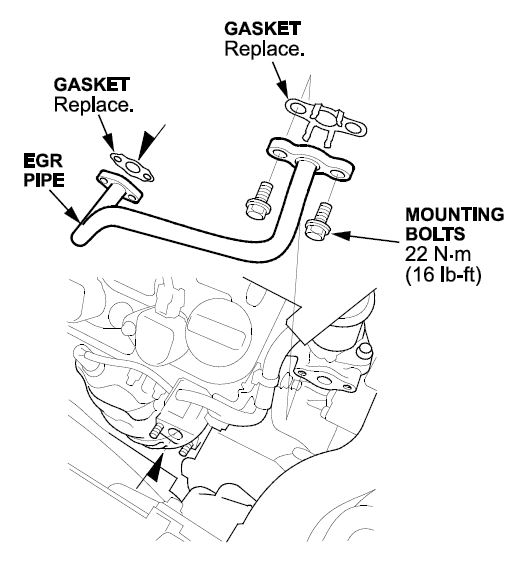

- Remove the EGR lower pipe nuts.

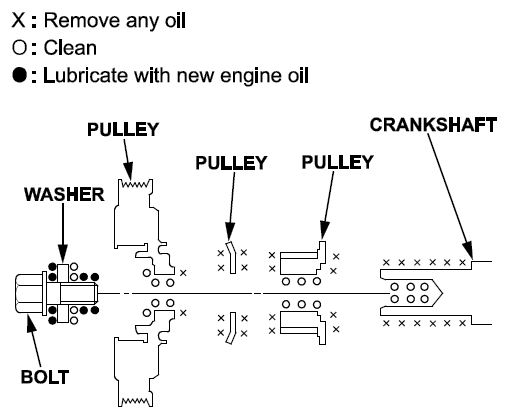

- Remove the crankshaft pulley bolt but not the pulley.

NOTE: Make sure to apply new oil to the bolt flange and threads before reinstallation.

- Lower the vehicle.

- Disconnect the MAP sensor connector and the breather pipe, then remove the intake air duct.

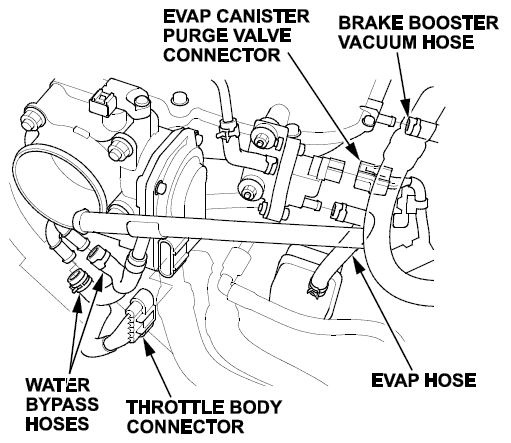

- Disconnect the throttle body connector, the EVAP canister purge valve connector, the EVAP hose, the brake booster vacuum hose, and the vacuum hose.

- Disconnect and plug the water bypass hoses.

- Remove the drive belt.

- Remove the drive belt auto-tensioner.

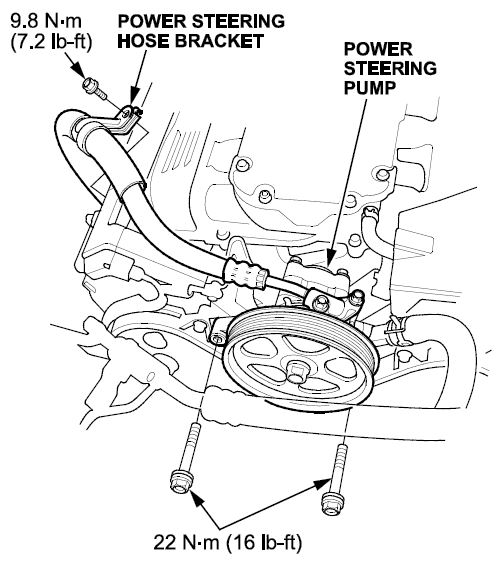

- Remove the power steering pump bolts, the power steering bracket then secure the power steering pump out of the way.

NOTE: Do not remove any of the hoses.

- Remove the engine harness holder bolt on the side engine mount.

- Set the engine to TDC cylinder one.

- Remove the crankshaft pulley.

- Remove the timing belt.

- Remove the timing belt idler pulley.

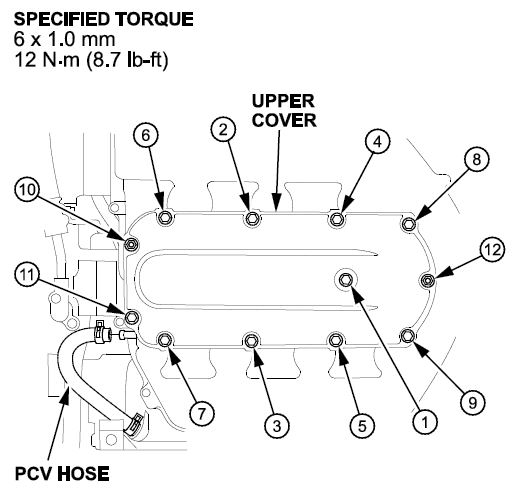

- Remove the engine intake upper cover bolts and nuts. Then remove the cover and the PCV hose.

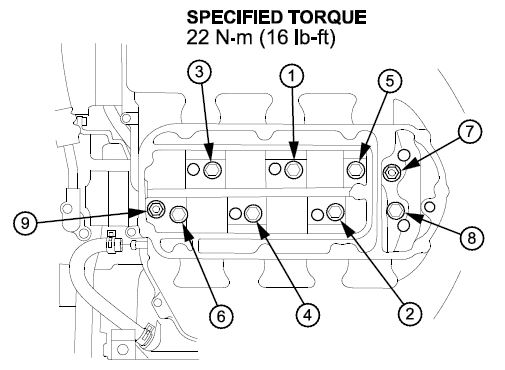

- Remove the intake manifold bolts and nuts in three steps, then remove the intake manifold.

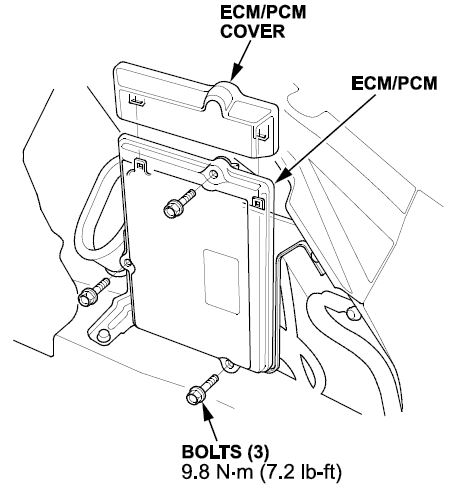

- Remove the PCM cover and connectors. Disconnect the battery cables from the underhood fuse box.

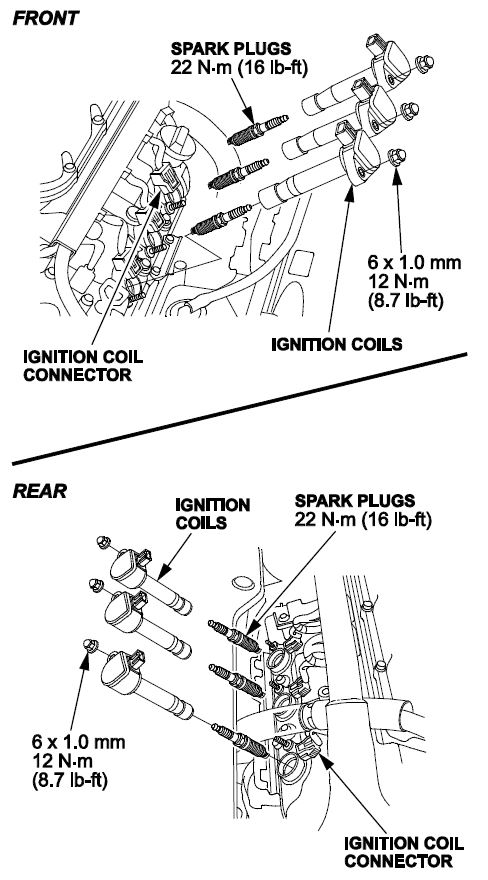

- Remove the appropriate Ignition coils based on the diagnosis.

NOTE: Depending on the diagnosis, you will either have to remove the rear bank ignition coils or both ignition coil banks.

- Depending on the diagnosis, remove some or all of the following components:

- ECT sensor connector

- Front rocker arm oil pressure switch connector

- Rear rocker arm oil pressure switch connector

- CMP sensor connector

- Front A/F sensor one connector

- Rear A/F sensor one connector

- Front secondary HO2S connector

- Rear secondary HO2S connector

- Rocker arm oil control solenoid A connector (bank one) Rocker arm oil control solenoid A connector (bank two)

- Rocker arm oil control solenoid B connector (bank one)

- Alternator connector and positive alternator cable

- A/C clutch switch connector

- EGR 5P valve connector

- Engine ground

- Knock sensor

- Fuel injector connectors and clips

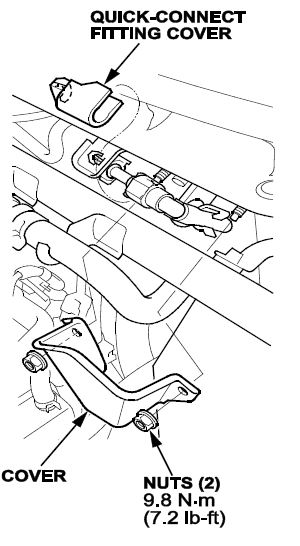

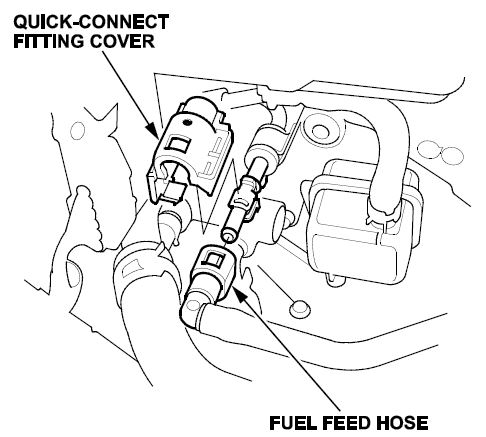

- Remove the quick-connect fitting cover, then disconnect the fuel feed hose.

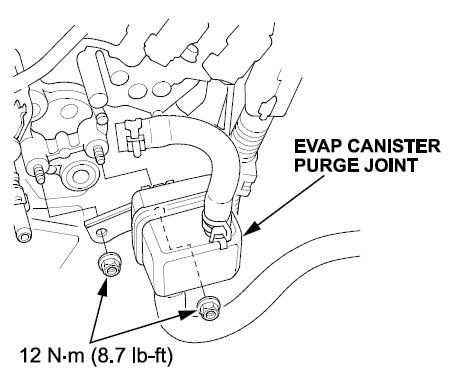

- Remove the EVAP canister purge joint with the bracket.

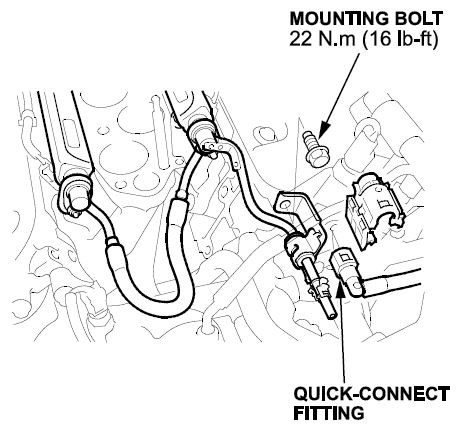

- Remove the fuel rail connecting joint hose.

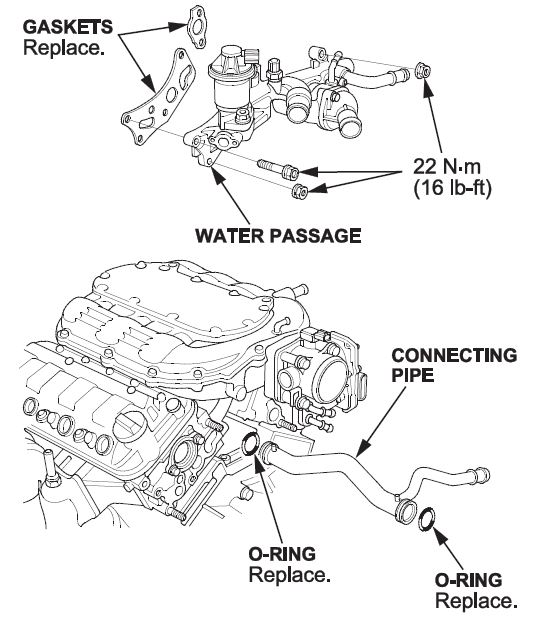

- Separate the water passage from the heads.

- Remove the appropriate WU-TWC depending on diagnosis.

NOTE: Set the WU-TWC aside and cover the opening with shop towels to prevent coolant from entering.

- Remove the appropriate head with the injector base attached.

NOTE: Depending on diagnosis, you will remove the rear bank head or both heads.

- Measure the head bolts to determine if they need replacement. If either diameter is less than 3 mm (0.445 in), replace the cylinder head bolt.

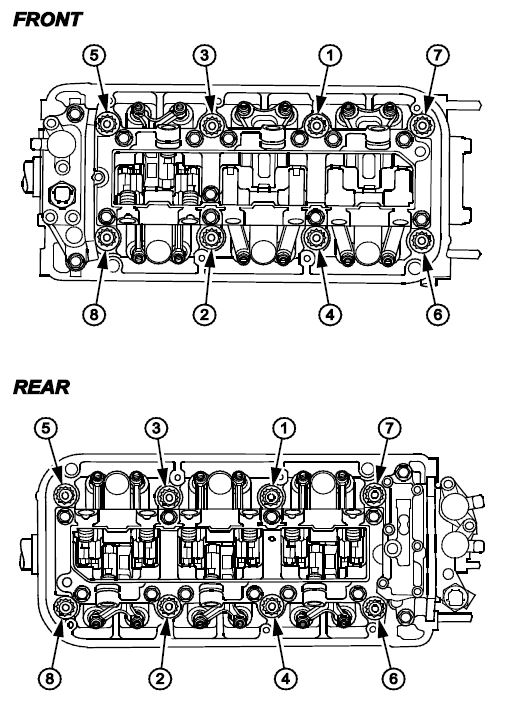

NOTE: Torque the bolts using the following steps for reinstallation.

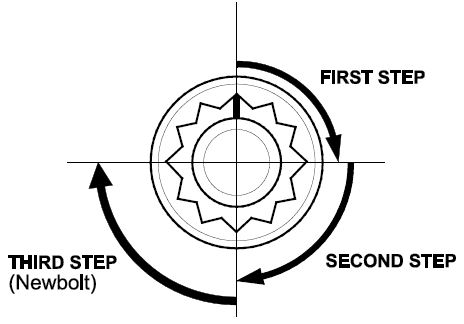

- First step: torque the cylinder bolts in sequence to 29 N•m (22 lb-ft).

- Second step: tighten in sequence an additional 90 degrees.

- Third step: tighten in sequence an additional 90 degrees.

- If the bolts are new, tighten an additional 90 degrees.

- Raise the vehicle.

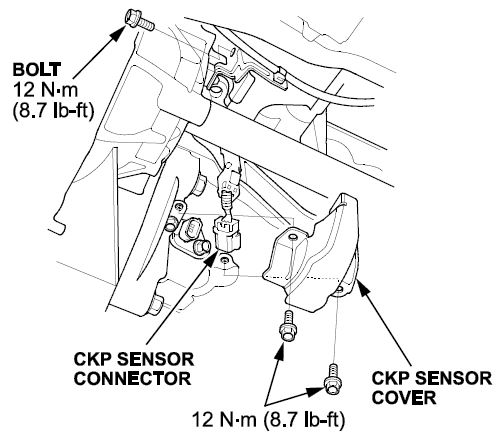

- Remove the CKP sensor cover and bolts, then disconnect the CKP sensor connector.

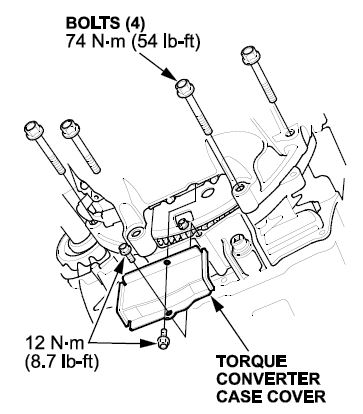

- Remove the torque converter case cover and the four bolts securing the oil pan to the transmission.

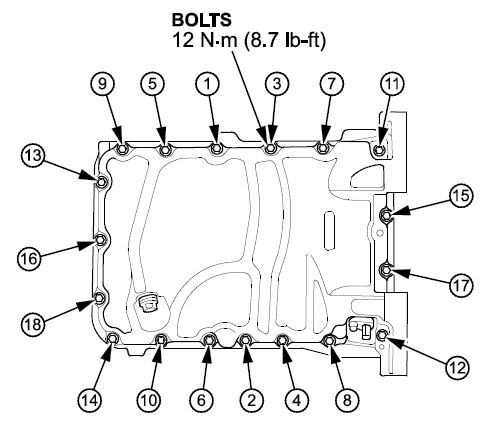

- Remove all bolts securing the oil pan.

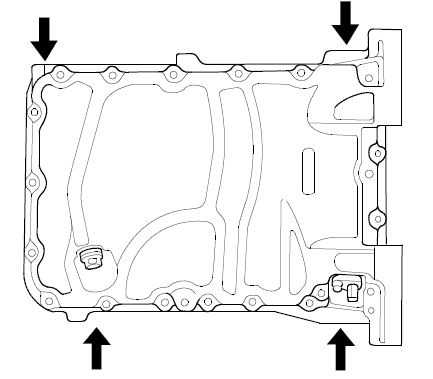

- Using a flat blade screwdriver, separate the oil pan from the engine block in the areas shown.

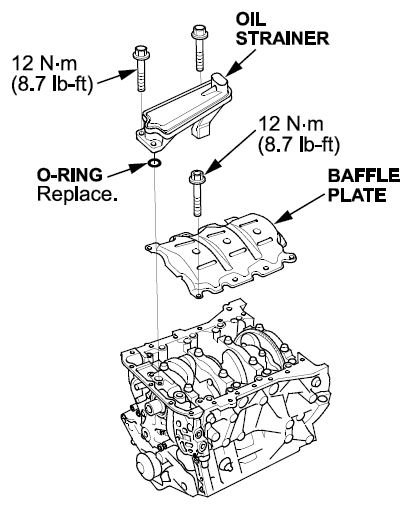

- Remove the oil strainer and baffle plate.

- Lower the vehicle to a comfortable working height, and place a clean shop towel around the cylinder wall to prevent debris from entering the coolant passage.

- Remove the appropriate piston depending on diagnosis, then go to PISTON CLEANING PROCEDURE.

NOTE: When removing the piston rod caps, be sure and keep all caps and bolts with their corresponding pistons for reassembly purpose.

Piston Cleaning and Ring Replacement Procedure

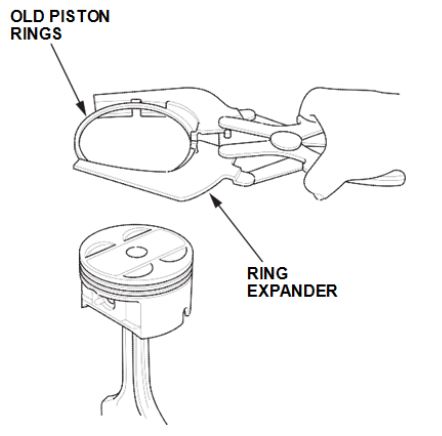

- Remove the piston rings from the piston using a ring expander. Be careful not to damage the piston.

- Spray the piston head and piston ring grooves thoroughly with Honda throttle plate cleaner.

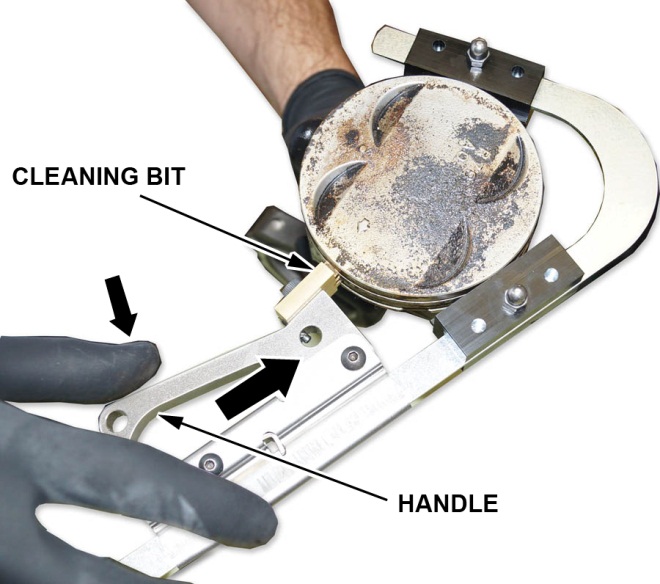

- While holding the piston upright in your left hand, take the piston ring groove cleaner tool in your right hand and line up the cleaner tool guides with the second (middle) piston ring groove.

- Press the handle on the piston ring groove cleaner tool and slide the cleaning bit onto the appropriate piston ring grooves.

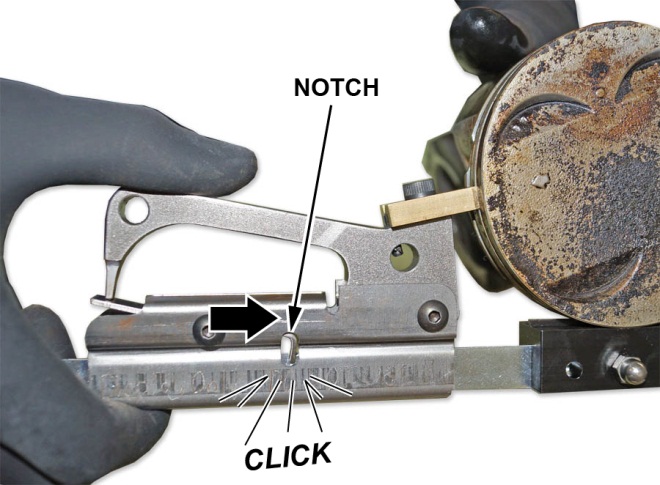

- Once the cleaning bit is in the appropriate ring grooves of the piston, make sure the tool handle clicks into place.

NOTE: There is only one notch on the tool for the handle to engage.

- Hold the piston steady and rotate the tool counter-clockwise five to six times to remove any carbon deposits in the piston ring grooves. Do not rotate the tool clockwise.

NOTE: You can watch this procedure in the Tech2Tech segment “How to Clean Piston Ring Grooves”.

- Remove the piston groove cleaning tool and clean off the carbon from the tool bit.

- Finish cleaning the piston with throttle plate cleaner and the nylon brush. Do not use a steel wire brush.

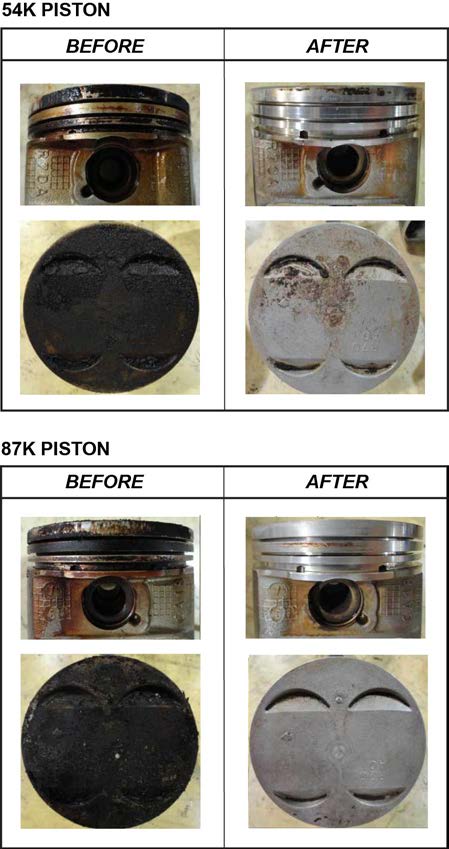

NOTE: Below are some examples of before and after pictures. Depending on mileage and running conditions, the pistons will achieve different levels of cleanliness.

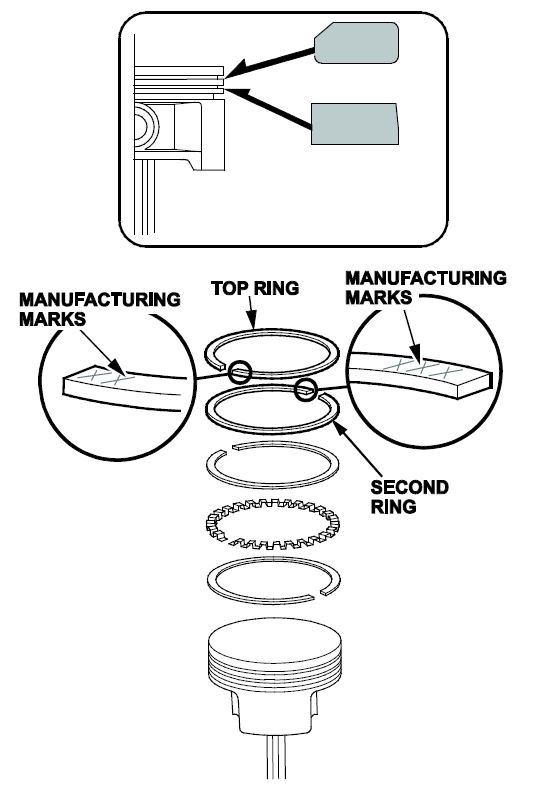

- Install the piston rings as shown.

NOTE: The first (top) ring has a 1D manufacturing mark and the second (middle) ring has an SPR manufacturing mark.

The manufacturing marks must be facing upward.

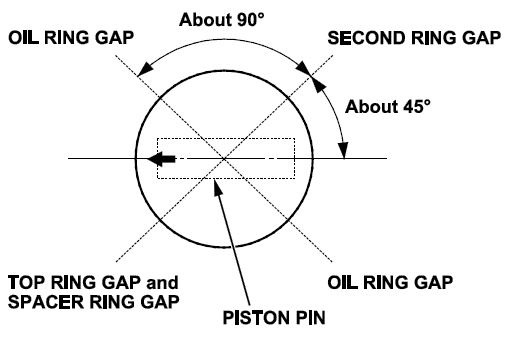

- Position the ring end gaps as shown.

NOTE: If the ring gaps are not positioned correctly, excessive blowby may occur.

- Apply new engine oil to the piston, the inside of the piston ring compressor, and the cylinder bore.

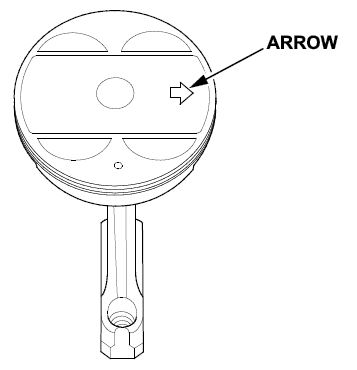

- Install the piston/connecting rod assembly into the cylinder bore with the arrow on top of the piston facing the timing belt side of the engine.

NOTE: Be careful not to damage the cylinder wall when installing the piston.

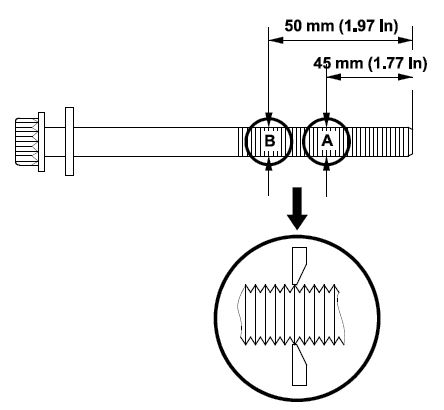

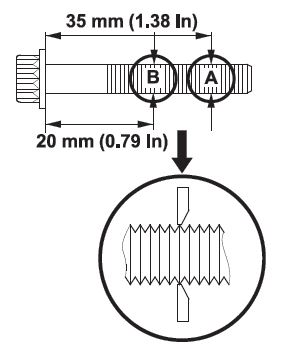

- Measure the diameter of the connecting rod bolts to determine if they need replacement. Calculate the difference in diameter between point A and point B. It should not be more than 0–0.1 mm (0–0.004 in).

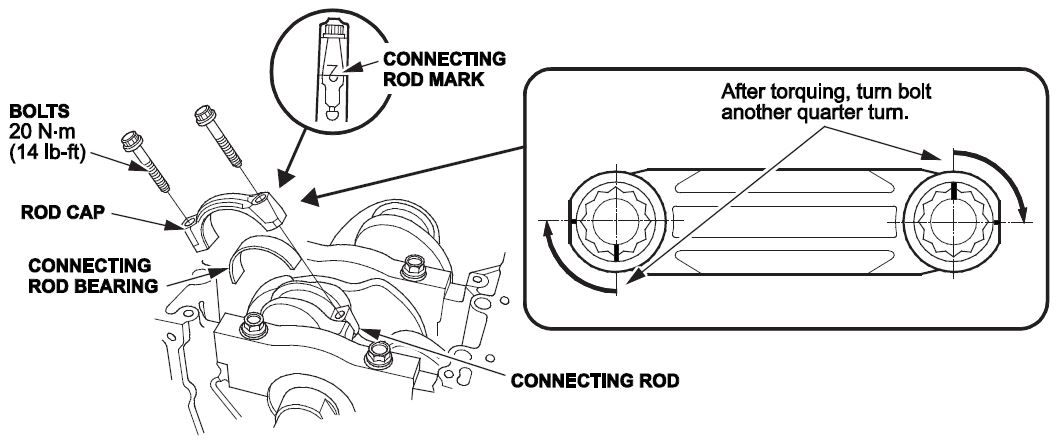

- Apply new oil to the connecting rod bolt threads and flanges. Torque the bolts to 20 N•m (14 lb-ft) then tighten the connecting rod bolts an additional 90 degrees.

- Reinstall the remaining components in the reverse order of removal.

- Replace spark plugs 1–4.

- Replace the oil filter and refill all fluids.

- Do the idle learn procedure.

END.

5 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

| HONDA | PILOT | 2009-2013 |

1 Associated Document

Service Bulletin Document

A13-082

May 18, 2015

51869-02164 Version 7

SB-10083965-2280.pdf 2670.231KB

Loading...

Loading...

Reprogramming

i-HDS Diagnostic Software and J2534 Reprogramming Software

Honda J2534 Pass-Thru User Guide

Honda J2534 Pass-Thru Software Download

i-HDS Diagnostic Software and J2534 Reprogramming Software

American Honda Motor Co., Inc. ("Honda") offers the i-HDS (Honda Diagnostic System) software suite for the diagnosis and repair of electronic systems on Honda and Acura automobiles, and for the reprogramming of electronic control units (including, but not limited to, ECMs and PCMs). This software provides access to all Honda and Acura

automobiles, and for the reprogramming of electronic control units (including, but not limited to, ECMs and PCMs). This software provides access to all Honda and Acura vehicle systems (access to the immobilizer security system requires a Security Professional level software subscription and Vehicle Security Professional [VSP] registration with NASTF). To use the i-HDS software, you need to purchase one of our convenient subscription options. In addition, you will need a pass-thru Vehicle Communication Device (VCI) that is compliant with SAE J2534-1 and J2534-2 in order to communicate with the vehicle

vehicle systems (access to the immobilizer security system requires a Security Professional level software subscription and Vehicle Security Professional [VSP] registration with NASTF). To use the i-HDS software, you need to purchase one of our convenient subscription options. In addition, you will need a pass-thru Vehicle Communication Device (VCI) that is compliant with SAE J2534-1 and J2534-2 in order to communicate with the vehicle

Vehicle Communication Interfaces (VCI)

The i-HDS software supports the use of a generic pass-thru VCI that is compliant with SAE J2534-1 and J2534-2. However, Honda recommends the Denso DST-i or the Bosch MVCI for use on Honda and Acura vehicles, as Honda has worked closely with these manufacturers to ensure their hardware and our software interact safely and within the J2534-1 and -2 specifications, for both diagnostics and reprogramming. If you choose to use a generic VCI, please carefully consider the customer and technical support options you will receive from your chosen device supplier. Honda does not provide technical or customer support for generic VCI devices.

vehicles, as Honda has worked closely with these manufacturers to ensure their hardware and our software interact safely and within the J2534-1 and -2 specifications, for both diagnostics and reprogramming. If you choose to use a generic VCI, please carefully consider the customer and technical support options you will receive from your chosen device supplier. Honda does not provide technical or customer support for generic VCI devices.

The VCI Application Table below lists devices that either are approved and supported by Honda or are known to have completed and passed an independent, exhaustive validation program with our i-HDS software suite.

| VCI Name | Manufacturer | Version Information | Notes | |

|---|---|---|---|---|

| Firmware | J2534 API | |||

| DST-i | DENSO | 2.02.0002* | 04.04 | This is the current generation VCI used by Honda and Acura dealers. Honda routinely validates the functionality and provides customer support for this device. dealers. Honda routinely validates the functionality and provides customer support for this device. |

| DST-nano | DENSO | 2.02.0002* | 04.04 | This is the current generation VCI used by Honda Canada Inc. Honda and Acura dealers. Honda routinely validates the functionality and provides customer support for this device. dealers. Honda routinely validates the functionality and provides customer support for this device. |

| MVCI | Bosch | 3.01.60* | 04.04 | This is the previous generation VCI used by Honda and Acura dealers. Honda routinely validates the functionality and provides customer support for this device. dealers. Honda routinely validates the functionality and provides customer support for this device. |

| MongoosePro Honda |

Drew Technologies | 1.9.5** | 04.04 | This company has completed an independent i-HDS validation and claims it to function with the i-HDS software. Honda does not provide ongoing validation, nor customer support for this device. |

| d-briDGe Pro | Dearborn Group | 3.303** | 04.04 | This company has completed an independent i-HDS validation and claims it to function with the i-HDS software. Honda does not provide ongoing validation, nor customer support for this device. |

* These versions may have been superseded. Honda provides the latest supported versions to current i-HDS subscribers.

** Version used in validation program. See Terms and Conditions and Important Notice Regarding Reprogramming below for more details.

Reprogramming with the J2534 Rewrite Application in i-HDS

Included in the i-HDS software suite is a new reprogramming application called J2534 Rewrite. This application is made available to all subscribers of the i-HDS software suite and replaces the previous generation software, J2534 Honda Pass-thru Reprogramming Software.

This new application is compatible with generic VCIs that comply with SAE J2534. It must be used to reprogram any Honda/Acura vehicle equipped with ECUs that support reprogramming. Refer to the table below for legacy applicability for the programming of ECMs and PCMs. Though system dependent, late-model vehicles may be equipped with other ECUs that support reprogramming as well, e.g. ABS or VSA. J2534 Rewrite must be used to reprogram these control modules, as instructed in an applicable service bulletin.

vehicle equipped with ECUs that support reprogramming. Refer to the table below for legacy applicability for the programming of ECMs and PCMs. Though system dependent, late-model vehicles may be equipped with other ECUs that support reprogramming as well, e.g. ABS or VSA. J2534 Rewrite must be used to reprogram these control modules, as instructed in an applicable service bulletin.

As shown in this table, not all legacy Honda/Acura models are equipped with a reprogrammable ECM/PCM. Furthermore, all 2007 and later models not listed in the table are fully supported with this application.

models are equipped with a reprogrammable ECM/PCM. Furthermore, all 2007 and later models not listed in the table are fully supported with this application.

DST-i Information:

MVCI Information:

- J2534 Pass-Thru Programmer: TOPDON RLink J2534 is an advanced diagnostic and reprogramming tool that support all J2534 protocols, as well as D-PDU, CAN-FD and DoIP, ensuring compatibility with a wide range of modern vehicles. It offers extensive versatility with support for over 17 major automotive brands, including Chrysler, Ford, GM, Nissan, Toyota

, Honda, Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen

, Honda, Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen , Mercedes-Benz, and BMW

, Mercedes-Benz, and BMW , and so on, enjoy dealership-level functions at your fingertips

, and so on, enjoy dealership-level functions at your fingertips - All-in-One OEM Diagnostics: This J2534 ECU programming tool elevates your automotive repair capabilities to new heights by delivering complete OEM diagnosis. Boasting comprehensive full-system diagnostics, intuitive repair guides, advanced ECU programming and coding, common reset services, a vast library of repair information and more, this all-in-one solution empowers technicians to effortlessly tackle complex vehicle issues with ease

- Proven Performance You Can Trust: Backed by over 10000 real vehicle tests and benefit from a wealth of practical experience, this OEM reprogramming tool guarantees stable and exceptional performance. Supported by TOPDON's dedicated technical experts with in-depth knowledge of both auto repair and J2534 Pass-Thru programming, the RLink J2534 provides prompt and professional assistance, ensuring a smooth setup and reliable compatibility

- Integrated Excellence, Always Up-to-Date: Featuring the exclusive RLink Platform to provide a streamlined experience with one-click driver installation and management, ensuring flawless integration with your OE software, maintaining the original performance quality. The built-in operation guide makes mastering OE software quick and easy, so you can get started right away. Plus, with lifetime free updates, your diagnostics will stay current with the latest drivers and innovations

- Efficiency Meets Versatility: Engineered to support three CAN channels simultaneously - CAN FD and CAN-CC included, giving you the edge in fast troubleshooting. To perfectly synchronized with the OE software, please diagnose with active subscriptions and make sure your computer system is running a compatible 64-bit Windows version (7, 8, 10 or later) to fully leverage the power of RLink J2534. *We don't provide extra OE software

- 【J2534 PROTOCOL WITH SMARTLINKC】 LAUNCH X431 PRO3S+ ELITE scan tool with newly upgraded smartlinkC V2.0. The SmartLinkC is a communication interface supporting J2534 specifications. Of course, it also can be used as a J2534 PassThru device, working together with the PC installed with the OEM diagnostic software to perform the J2534 protocol.J2534 protocol is the only solution for problems ranging from driveability and loss of power to poor fuel economy.

- 【INTELLIGENT TOPOLOGY MAP TO FASTER FULL SYSTEMS DIAGNOSIS】 X431 PRO3S+ELITE bidirectional scan tool with new-added intuitive topology mapping. Harnesses intuitive topology mapping for comprehensive visualization of the vehicle all system. It shows all available control units in different colors, the numbers of system, the scanned system, and the scan results, bringing maximum convenience & superfast speed for you to do swift diagnosis & high-level repairs.

- 【TOP HARDWARE CONFIGURATION, UPGRADED OF LAUNCH X431 PRO3S+】 LAUNCH X431 PRO3S+ELITE diagnostic scanner possess with Android 10.0 OS; CPU 4-Core Processor, 2.0 GHz. Greatly increased the speed of running multiple task. 2.4GHz/5GHz; 6300mAh/7.6V stronger battery capacity; 10.1 Inch Touchscreen with 8MP camera; AUTO VIN; 4GB+64GB storage memory; 20X faster transmission rate, save more vehicle documents and customer data; Supports 25+ Software Languages, such as EN, DE, FR, SP nd JP and so on.

- 【3000+ ACTIVE TEST/BI-DIRECTIONAL CONTROL LAUNCH SCANNER】 LAUNCH X431 PRO3S+ELITE HD automotive scanner is a cost-effective bidirectional scanner that deserves owned by every repairing DIYers and mechanics. You can easily send command signal at fingertips from the scanner to various module actuators to test component integrity and functionality in minutes or even seconds to tell if replacement or repair is needed.

- 【COMPLETE 60+ HOT RESETS, CALIBRATION, INITIALIZATION, RELEARN】 LAUNCH X431 PRO3S+ELITE SmartLinkC escaner automotriz professional enjoys 60+ special service, such as Oil Reset, ABS brake bleed, EPB, SAS, BMS, Suspension, Injector reset, Power Balance, Turbo Calibration, VGT, Transmission Adaption, Throttle Adaptation, matching and etc. rigorous on-site testing has been performed to ensure 100% availability.

- ALL OF THE J2534 PROTOCOLS - This single unit has all of the protocols you need for your OEM J2534 reprogramming and diagnostics including the latest in DoIP and CanFD

- J2534 TECHNICAL SUPPORT - FREE for the life of the tool. Staffed by technicians who understand vehicle repair and J2534 Pass‑thru

- TOOLBOX WITH OEM APPLICATION DESCRIPTIONS - educational video tutorials and real-time news – Giving you the confidence and up-to-date knowledge to get the job done

- J2534 v05.00 API - The newest version of J2534 to give you the latest in pass-thru technology

- FUTURE PROOF WITH 4 CAN CHANNELS - Going beyond the 3 required by select Chrysler/FCA models, CarDAQ-Plus 3 also provides a 4th to meet the needs of future OEM applications

- 🌐【Works with Autel Elite II Elite MS908 MS908S Pro II MS908CV II MK908P MK908 Pro II】Autel J2534 work with these tools to program ECUs on specific BM.W/ BE.NZ for specific functions. ★★NOTE: J2534 CANNOT directly work with these single devices. After you received the J2534, you HAVE TO send us both the S/N(12 digits) of your scanner MS908S(etc.) and J2534. So, technically, Autel engineers can help you bind J2534 with your devices. If need any supports, contact us via: 🚘auteldirect @ outlook. com🚘.

- 🌐【SAE J2534-1 & J2534-2 Standards】Autel MaxiFlash Elite J2534 is a fully compliant SAE J2534-1 & SAE J2534-2 (March 2006) device, which performs standard PassThru J2534 functionality: Compatible with for Toyota

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility.

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility. - 🌐【High-speed Transmission Speed】Autel MaxiFlash Elite Reprogramming Device J2534 supports simultaneous communication definition in J2534-1, running 3 protocols at the same time, which greatly improves reprogramming and diagnostic speed. Embedded with the ARM9 Dual-core processor (clocked up to 500MHz), which further boosts the communicating speed to save more times and win more business.

- 🌐【Multiple Devices Connected with P-C】Autel MaxiFlash Elite J2534 also supports multiple device connections to the P-C, which can operate diagnostic and reprogramming functions on more than one vehicle at the same time. Autel MaxiFlash Elite J2534 built-in wireless and data storage, which can update via Internet. It also ensures quickly reprogramming even the newest controllers.

- 🌐【Extensive Compatibility】Autel MaxiFlash J2534 is compatible with Toyota

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

- CUSTOM-DESIGNED FOR USE WITH FORSCAN: Works with all FORScan compatible vehicles and is recommended by the FORScan Team

- DEALERSHIP-LEVEL DIAGNOSTICS: OBDLink EX supports all Ford protocols, modules, and advanced features of FORScan

- ELECTRONIC SWITCH allows FORScan to access all CAN buses simultaneously and enables advanced functions not possible with “toggle switch” adapters

- MAXIMUM THROUGHPUT -- up to 20 times faster than “toggle switch” adapters

- ROCK-SOLID CONNECTION avoids data corruption and dropped packets

- 🌎【Autel All-in-1 Reprogramming Tool】As an OEM Vehicle interface for multiple makes, Autel J2534 pass-thru programmer is a multi-functional programming and communication device. Work with Autel MS909 Ultra Lite Elite 2 Pro MS909 MS909CV MS909EV to directly program on Merce.des-Be.nz & BM.W. Autel MaxiFlash VCI also works with P-C to download OEM vehicle software, seamlessly conduct OE-level diagnostic-programming-coding. Enhanced multi-protocol: SAE J2534/ CAN FD/ DoIP/ D-PDU/ RP1210, Autel Maxiflash VCI J2534 is a must have aftermarket programming device for any mechanic/ technician in the programming wo.rld!

- 📢【Kind Tips】After purchasing the J2534, you need to update the firmware first. Steps: ✅𝟭. Access to Autel official website > click "Support" - "Download" > download "Maxi P-C Suite" APP ✅𝟮. connect J2534 and compu-ter via USB Cable ✅𝟯. Install "Maxi P-C Suite" APP on the compu-ter and update to the latest version > go to the vehicle website to purchase the corresponding OEM software for use. 📢Note: J2534 is only compatible with Windows compu-ters, and OEM software needs to be purchased.

- 🌎【Compatible with Autel Elite II Pro Ultra Lite MS909 MS909CV MS909EV & P-C/ WIND.OWS】This 2025 latest Autel J2534 Pass-Thru VCI is 100% compatible with Autel Elite II Pro Ultra Lite MS909 MS909CV MS909EV to perform advanced functions from diagnose to programming. Besides, it can connect to P-C with Easy Steps: 1) Connect to P-C via a USB cable 2) download OEM vehicle software 3) Start Diagnose. Take For.d for example, you can download OEM software on mot.orcraft.erservi.ce website, such as: For.d Diagnostic Software downloads, As B.uilt Data, Updated Cali.bration information, then use different software do relevant features.

- 🌎【Enhanced Protocol: CAN FD/DoIP/D-PDU/RP1210/J2534】Autel MaxiFlash JVCI is a blueto.oth communicate device, it supports latest CAN FD DoIP CAN protocols, compliant with automotive D-PDU/ J2534/ RP1210 standards. It can perform standard PassThru J2534 functions: compatible with Toyota

Techstream, Volvo VIDA, Honda HDS, Jaguar Land Rover IDS and BM.W 3G for OEM diagnostics. CAN FD protocol is mainly for GM 2019+, DoIP protocol is mainly for Volvo 2018+, for L-and Rover/for Jaguar 2017+, for BM.W F chassis and G chassis.

Techstream, Volvo VIDA, Honda HDS, Jaguar Land Rover IDS and BM.W 3G for OEM diagnostics. CAN FD protocol is mainly for GM 2019+, DoIP protocol is mainly for Volvo 2018+, for L-and Rover/for Jaguar 2017+, for BM.W F chassis and G chassis. - 🌎【ECU Programming Coding】Tailored to ECU programming & coding, Autel J2534 Pass-Thru VCI can communicate effectively with the ECU across different vehicle makes and models. After you purchased OEM software, J2534 pass thru programmer can work with P-C: Update vehicle software to the latest version, optimize the histo.rical le.gacy of the car's old version, Replace existing software/ firmware, reprogram component after replacement.

SEOCONTENT-START

CUSTOMER INFORMATION: The information in this bulletin is intended for use only by skilled technicians who have the proper tools, equipment,

and training to correctly and safely maintain your vehicle. These procedures should not be attempted by “do-it-yourselfers,” and you should not

assume this bulletin applies to your vehicle, or that your vehicle has the condition described. To determine whether this information applies, contact

an authorized Honda automobile dealer.

© 2016 American Honda Motor Co., Inc. – All Rights Reserved Page 1 of 24

Service Bulletin 13-082

May 18, 2015 51869-02164 Version 7

Warranty Extension: MIL Comes On With DTCs P0301 thru P0304

Supersedes 13-082, dated September 12, 2015, to revise the information highlighted in yellow.

AFFECTED VEHICLES

Year

Model

Trim

VIN Range

2009–13

Pilot

ALL

Check the iN VIN Status for Eligibility

REVISON SUMMARY

• Under REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT, Replace Parts as Needed for Repair Procedure B, changed bolt count for the 12 x 163 Washer bolt (P/N 90005-PAA-A01) under Cyl 1-4 from 8 to 16. Also changed the bolt count for Connecting Rod Bolt from 8 to 6.

CORRECTIVE ACTION

2009–11 Models: Complete the diagnosis procedure and if necessary, update the PCM software and replace the affected spark plugs. If the vehicle returns after the updated PCM software and spark plug replacement have been installed, clean the pistons and replace the pistons rings along with the spark plugs (Procedure B).

NOTE: Make sure the software update has been completed, spark plugs replaced (Procedure A), and the vehicle returned to the customer before making any additional repairs. Failure to do so will result in claim review by your DPSM and possible debit.

2012–13 Models: Complete the diagnosis procedure and if necessary, clean the pistons and replace the pistons rings along with the spark plugs (Procedure B).

BACKGROUND

American Honda is announcing a powertrain warranty extension as a result of a settlement of a class action captioned, Soto et al.v. American Honda Motor Co., Inc., Case No. 3:12-cv-1377-SI (N.D. Cal.).

The piston rings on certain cylinders may rotate and align, which can lead to spark plug fouling. This can set DTCs P0301 No. 1 cylinder misfire detected, P0302 No. 2 cylinder misfire detected, P0303 No. 3 cylinder misfire detected, P0304 No. 4 cylinder misfire detected, and cause the MIL to come on.

American Honda is extending the powertrain warranty to cover repairs related to engine misfire (that triggers DTCs P0301 through P0304) to 8 years with unlimited mileage from the original date of purchase and has settled a class action based on this remedial measure.

This warranty extension does not apply to any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded or similar title under any state’s law.

CUSTOMER NOTIFICATION

Owners of affected vehicles were sent a class action settlement notice regarding this warranty extension starting in October 2013.

Before doing work on a vehicle, verify its eligibility by doing an iN VIN status inquiry.

Refer customers seeking information about settlement benefits to www.enginemisfiresettlement.com, or instruct them to call 888-888-3082.

Page 2 of 24

DIAGNOSIS

1. Connect the HDS and check for the following DTCs: P0301 No. 1 Cylinder Misfire Detected, P0302 No. 2 Cylinder Misfire Detected, P0303 No. 3 Cylinder Misfire Detected, P0304 No. 4 Cylinder Misfire Detected.

Are any of these DTCs stored?

YES – Go to step 2.

NO – Stop. This bulletin does not apply. Continue with normal troubleshooting.

2. Remove and check the spark plug(s) on the affected cylinders (example: if P0301 is stored, check the spark plug on cylinder No. 1).

Are the spark plug(s) fouled?

YES – Go to step 3.

NO – Stop. This bulletin does not apply. Continue with normal troubleshooting.

Page 3 of 24

3. Check the PCM software version P/N located above the PGM FI Data List. All 2012–13 vehicles are up to date, go directly to step 4.

Year/Model

Program ID (or later)

Program P/N (or later)

2009–10 Pilot (2WD)

N0A570

37805-RN0-A57

2009–10 Pilot (4WD)

N0A770

37805-RN0-A77

2011 Pilot (2WD)

N0A630

37805-RN0-A63

2011 Pilot (4WD)

N0A830

37805-RN0-A83

2012–13 Pilot (ALL)

Software Updated from Factory

Is the PCM Program ID and/or Program P/N the same or newer than what is listed above, 2009–11 model years only?

NO – The PCM software needs to be updated. Go to REPAIR PROCEDURE A.

YES – The correct software is installed. The piston rings on select cylinders need to be replaced. Go to step 4.

IMPORTANT NOTICE: The PCM software must first be updated with the correct version, replace spark plugs and the vehicle returned to the customer. Piston cleaning and piston ring replacement, as described below, should only be done after the customer has returned with a second failure or if the vehicle’s software is the correct version. Failure to follow this process correctly may result in a full debit of the warranty claim to your dealer.

4. Note which DTCs are stored in the vehicle.

Does the vehicle have DTC P0304 stored? (Any combination of DTCs P0301, P0302, P0303, P0304 may also be stored.)

YES – Go to REPAIR PROCEDURE B for the cylinders listed, Cylinders 1–4: Clean the pistons, replace the piston rings, and replace the spark plugs.

NO – Go to REPAIR PROCEDURE B for the cylinders listed below:

• Cylinder 1–3: Clean the pistons and replace the pistons rings.

• Cylinder 1–4: Replace the spark plugs.

Page 4 of 24

WARRANTY CLAIM INFORMATION

2009–11 Models: Confirm PCM Software is or has been updated with the correct version, spark plugs 1–4 have been replaced and the vehicle returned to the customer (Procedure A). Piston cleaning and piston ring replacement along with the spark plugs, should be only be done after the customer has returned with a second failure or if the vehicles software is the correct version (Procedure B). Failure to follow this process correctly may result in a full debit of the warranty claim to your dealer.

2012–13 Models: Are equipped with updated software from the factory, no software updated is needed. Piston cleaning and piston ring replacement along with the spark plugs should be done (Procedure B).

FLAT RATE NOTE: The procedure in this bulletin is different than the service manual. This procedure does not require the complete removal of the power steering pump, catalytic converter(s), engine and transmission, or the crankshaft. As a result, the operation number is unique and the FRT is reduced (Procedure B).

2009–11 Pilot

OP#

Description

Flat Rate Time

Template ID

Failed Part Number

1171G9

2009–11 Pilot: Procedure A

Update the PCM and replace spark plugs 1–4 (includes diagnosis).

0.5 hr

13-082A

13011–R70–A02

1171H0

2009–11 Pilot: Procedure B

Replace piston rings 1–3 and replace spark plugs 1–4 (includes diagnosis).

9.1 hrs

13011–R70–A02

1171H0B

2009–11 Pilot: Add if replacing piston rings on cylinder 4.

1.9 hrs

13011–R70–A02

2012–13 Pilot

OP#

Description

Flat Rate Time

Failed Part Number

1171H0

2012–13 Pilot:

Replace piston rings 1–3 and replace spark plugs 1–4 (includes diagnosis).

9.1 hrs

13011–5G0–A01

1171H0B

2012–13 Pilot: Add if replacing piston rings on cylinder 4.

1.9 hrs

13011–5G0–A01

Defect Code: 5V500

Symptom Code: JC000

Skill Level: Repair Technician

PARTS INFORMATION

NOTE: Do the DIAGNOSIS first to determine which cylinders you will need to repair.

REPAIR PROCEDURE A – SOFTWARE UPDATE AND CYLINDERS 1–4 SPARK PLUG REPLACEMENT

Required Parts

Part Name

Part Number

Quantity

Spark Plugs (2009–11 All)

12290-R70-A01

4

Spark plugs (2012–13 All)

12290-R71-L01

4

Page 5 of 24

REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT

Required Parts

Part Name

Part Number

Cyl 1-3

Cyl 1-4

Cyl. Gasket (Fr Cylinder Head)

12251-R70-A01

1

Cyl. Gasket (Rr Cylinder Head)

12261-R70-A01

1

1

DrainWasher 14 mm

94109-14000

1

1

EGR Pipe Gasket A

18716-R70-A01

1

1

EGR Pipe Gasket B

18719-R70-A01

1

1

Ex. Chamber Gasket

18115-R70-A01

1

2

Ex. Pipe Gasket

18212-SA7-003

2

2

Head Gasket Fr (Valve Cover)

12030-R70-A00

1

Head Gasket Rr. (Valve Cover)

12050-R70-A00

1

1

In. Manifold Gasket (Intake Top Cover)

17146-R70-A01

1

1

In. Manifold Gasket (2009–10 2WD)

17105-RCA-A01

1

1

In. Manifold Gasket (2009–13 4WD & 2011–13 2WD)

17105-RCJ-A01

1

1

Oil Filter

15400-PLM-A02

1

1

O-ring (7.47 mm x 3.6 mm)

91301-PLC-000

2

2

O-ring (31.2 mm x 4.1 mm)

91314-PH7-003

2

2

Piston Ring Set

13011-5G0-A02

3

4

Pre-chamber Gasket

18393-SDB-A00

1

1

Self-locking Nut (8 mm)

90212-RCA-A01

4

8

Self-locking Nut (10 mm)

90212–SA5-003

9

9

Spark Plug (2009–11 All)

12290-R70-A01

4

4

Spark plug (2012–13 All)

12290-R71-L01

4

4

Strainer O-ring

15221-RYE-A01

1

1

Timing Belt Bolt

14551-RCA-A01

1

1

Water Gasket Fr.

19411-P8A-A03

1

1

Water Gasket Rr.

19412–P8A-A02

1

1

Replaced Parts as Needed for Repair Procedure B

Part Name

Part Number

Cyl 1-3

Cyl 1-4

Connecting Rod Bolt (May require Up to 6 bolts per cylinder head)

13204–P8A–A01

6

8

Washer-Bolt (12 x 163) (May require up to 8 bolts per cylinder head)

90005–PAA–A01

8

16

Page 6 of 24

REQUIRED MATERIALS – REPAIR PROCEDURE B

Material Description

Part Number

Quantity

Honda Long-Life Antifreeze/Coolant Type 2

OL999–9011

3 gallons

Genuine Honda Motor Oil 0W–20

08798–9036

6 quarts

Genuine Honda Motor Oil 5W–20 (if requested) (2009-11)

08798–9032

6 quarts

Hondabond HT (1 Tube Repairs 5 Vehicles)

08718–0004

1 tube

Genuine Honda Throttle Plate Cleaner

08700–9204

Nylon Parts Cleaning Brush

(commercially available)

5/16 ID Flexible Hose

(commercially available)

TOOL INFORMATION – REPAIR PROCEDURE B

Tool Description

Tool Number

Quantity

Piston Ring Groove Cleaner

07AAZ–TA5A100

1

REPAIR PROCEDURE A – SOFTWARE UDPATE AND CYLINDERS 1–4 SPARK PLUG REPLACEMENT

1. For 2009–11 models only, update the PCM software. Refer to Service Bulletin 01-023, Updating Control Units/Modules.

2. Replace spark plugs on cylinders 1–4, then return the vehicle to the customer.

REPAIR PROCEDURE B – PISTON CLEANING AND RING REPLACEMENT

2009–11 Models: Confirm PCM software is or has been updated with the correct version, spark plugs 1–4 have been replaced and the vehicle returned to the customer (Procedure A). Piston cleaning and piston ring replacement along with the spark plugs should only be done after customer has returned with a second failure or if the vehicles software is the correct version (Procedure B). Failure to follow this process correctly may result in a full debit of the warranty claim to your dealer.

2012–13 Models: Are equipped with updated software from the factory, no software update is needed. Piston cleaning and piston ring replacement along with the spark plugs should only be done after the diagnosis of the spark plugs has concluded that (Procedure B) is required.

The following service manual procedures have been used in full or in part within this service bulletin. For more detail on these procedures, and torque specifications for some components, refer to the appropriate electronic service manual.

• Battery Terminal Disconnection and Reconnection

• Fuel Pressure Relieving

• Fuel Line/Quick-Connect Fitting Removal

• Air Cleaner Removal/Installation

• Splash Shield Replacement

• Drive Belt Removal/Installation

• Engine Oil Replacement

• Coolant Replacement

• Hydraulic Power Steering Fluid Check/Replacement

• Intake Manifold Removal and Installation

• Timing Belt Removal and Installation

• Warm Up-TWC Removal/Installation

• Cylinder Head Cover Removal

• Cylinder Head Removal and Installation

• Piston Ring Replacement

• PCM Idle Learn Procedure

• Valve Adjustment

Page 7 of 24

Piston Removal Procedure

• Use fender covers to avoid damaging painted surfaces.

• To avoid damaging any wires and terminals, unplug the circuit connectors carefully while holding the connector portion.

• Mark all the circuits and hoses to avoid misconnection. Make sure they do not contact other circuit wiring, hoses, or interfere with other parts.

1. Relieve the fuel pressure.

2. Remove both front wheels so you can fully lower the vehicle.

3. Remove the intake duct.

4. Do the battery removal procedure.

5. Disconnect the fuel feed hose line at the bulkhead.

Page 8 of 24

6. Remove the engine cover.

7. Remove the radiator cap.

8. Raise the vehicle.

9. Remove the front splash shield.

10. Drain the engine oil.

11. Loosen the drain plug on the radiator, and drain the coolant.

Page 9 of 24

12. Install a 5/16th inner diameter rubber hose on the drain bolt at the rear of the engine block, loosen the drain bolt, and drain all remaining coolant. Then disconnect the oil pressure switch connector.

13. Remove the subframe stiffener.

14. Remove exhaust pipe A.

Page 10 of 24

15. Depending on the diagnosis, remove the appropriate WU-TWC support bracket bolts.

16. Remove the EGR lower pipe nuts.

17. Remove the crankshaft pulley bolt but not the pulley.

NOTE: Make sure to apply new oil to the bolt flange and threads before reinstallation.

18. Lower the vehicle.

19. Disconnect the MAP sensor connector and the breather pipe, then remove the intake air duct.

20. Disconnect the throttle body connector, the EVAP canister purge valve connector, the EVAP hose, the brake booster vacuum hose, and the vacuum hose.

Page 11 of 24

21. Disconnect and plug the water bypass hoses.

22. Remove the drive belt.

23. Remove the drive belt auto-tensioner.

24. Remove the power steering pump bolts, the power steering bracket then secure the power steering pump out of the way.

NOTE: Do not remove any of the hoses.

25. Remove the engine harness holder bolt on the side engine mount.

26. Set the engine to TDC cylinder one.

27. Remove the crankshaft pulley.

28. Remove the timing belt.

29. Remove the timing belt idler pulley.

Page 12 of 24

30. Remove the engine intake upper cover bolts and nuts. Then remove the cover and the PCV hose.

31. Remove the intake manifold bolts and nuts in three steps, then remove the intake manifold.

32. Remove the PCM cover and connectors. Disconnect the battery cables from the underhood fuse box.

Page 13 of 24

33. Remove the appropriate Ignition coils based on the diagnosis.

NOTE: Depending on the diagnosis, you will either have to remove the rear bank ignition coils or both ignition coil banks.

34. Depending on the diagnosis, remove some or all of the following components:

• ECT sensor connector

• Front rocker arm oil pressure switch connector

• Rear rocker arm oil pressure switch connector

• CMP sensor connector

• Front A/F sensor one connector

• Rear A/F sensor one connector

• Front secondary HO2S connector

• Rear secondary HO2S connector

• Rocker arm oil control solenoid A connector (bank one)

• Rocker arm oil control solenoid A connector (bank two)

• Rocker arm oil control solenoid B connector (bank one)

• Alternator connector and positive alternator cable

• A/C clutch switch connector

• EGR 5P valve connector

• Engine ground

• Knock sensor

• Fuel injector connectors and clips

Page 14 of 24

35. Remove the quick-connect fitting cover, then disconnect the fuel feed hose.

36. Remove the EVAP canister purge joint with the bracket.

37. Remove the fuel rail connecting joint hose.

Page 15 of 24

38. Remove the EGR pipe mounting bolts, then remove the EGR pipe.

39. Separate the water passage from the heads.

Page 16 of 24

40. Remove the appropriate WU-TWC depending on diagnosis.

NOTE: Set the WU-TWC aside and cover the opening with shop towels to prevent coolant from entering.

41. Remove the appropriate head with the injector base attached.

NOTE: Depending on diagnosis, you will remove the rear bank head or both heads.

Page 17 of 24

42. Measure the head bolts to determine if they need replacement. If either diameter is less than 11.3 mm (0.445 in), replace the cylinder head bolt.

NOTE: Torque the bolts using the following steps for reinstallation.

• First step: torque the cylinder bolts in sequence to 29 N•m (22 lb-ft).

• Second step: tighten in sequence an additional 90 degrees.

• Third step: tighten in sequence an additional 90 degrees.

• If the bolts are new, tighten an additional 90 degrees.

43. Raise the vehicle.

44. Remove the CKP sensor cover and bolts, then disconnect the CKP sensor connector.

Page 18 of 24

45. Remove the torque converter case cover and the four bolts securing the oil pan to the transmission.

46. Remove all bolts securing the oil pan.

47. Using a flat blade screwdriver, separate the oil pan from the engine block in the areas shown.

Page 19 of 24

48. Remove the oil strainer and baffle plate.

49. Lower the vehicle to a comfortable working height, and place a clean shop towel around the cylinder wall to prevent debris from entering the coolant passage.

50. Remove the appropriate piston depending on diagnosis, then go to PISTON CLEANING PROCEDURE.

NOTE: When removing the piston rod caps, be sure and keep all caps and bolts with their corresponding pistons for reassembly purpose.

Piston Cleaning and Ring Replacement Procedure

1. Remove the piston rings from the piston using a ring expander. Be careful not to damage the piston.

2. Spray the piston head and piston ring grooves thoroughly with Honda throttle plate cleaner.

Page 20 of 24

3. While holding the piston upright in your left hand, take the piston ring groove cleaner tool in your right hand and line up the cleaner tool guides with the second (middle) piston ring groove.

4. Press the handle on the piston ring groove cleaner tool and slide the cleaning bit onto the appropriate piston ring grooves.

5. Once the cleaning bit is in the appropriate ring grooves of the piston, make sure the tool handle clicks into place.

NOTE: There is only one notch on the tool for the handle to engage.

Page 21 of 24

6. Hold the piston steady and rotate the tool counter-clockwise five to six times to remove any carbon deposits in the piston ring grooves. Do not rotate the tool clockwise.

NOTE: You can watch this procedure in the Tech2Tech segment “How to Clean Piston Ring Grooves”.

7. Remove the piston groove cleaning tool and clean off the carbon from the tool bit.

8. Finish cleaning the piston with throttle plate cleaner and the nylon brush. Do not use a steel wire brush.

Page 22 of 24

NOTE: Below are some examples of before and after pictures. Depending on mileage and running conditions, the pistons will achieve different levels of cleanliness.

Page 23 of 24

9. Install the piston rings as shown.

NOTE: The first (top) ring has a 1D manufacturing mark and the second (middle) ring has an SPR manufacturing mark. The manufacturing marks must be facing upward.

10. Position the ring end gaps as shown.

NOTE: If the ring gaps are not positioned correctly, excessive blowby may occur.

11. Apply new engine oil to the piston, the inside of the piston ring compressor, and the cylinder bore.

Page 24 of 24

12. Install the piston/connecting rod assembly into the cylinder bore with the arrow on top of the piston facing the timing belt side of the engine.

NOTE: Be careful not to damage the cylinder wall when installing the piston.

13. Measure the diameter of the connecting rod bolts to determine if they need replacement. Calculate the difference in diameter between point A and point B. It should not be more than 0–0.1 mm (0–0.004 in).

14. Apply new oil to the connecting rod bolt threads and flanges. Torque the bolts to 20 N•m (14 lb-ft) then tighten the connecting rod bolts an additional 90 degrees.

15. Reinstall the remaining components in the reverse order of removal.

16. Replace spark plugs 1–4.

17. Replace the oil filter and refill all fluids.

18. Do the idle learn procedure.

END.

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.