| “This site contains affiliate links for which OEMDTC may be compensated” |

A14-078

December 23, 2015

00317-01777 Version 4

Excessive Vibration Between 30 and 65 MPH

Supersedes 14-078, dated April 13, 2015, to revise the information highlighted in yellow

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2012 | Pilot | 2WD | 5FNYF3H..CB029003 and earlier with Continental PCM |

| 2012 | Pilot | 4WD | 5FNYF4H..CB058213 and earlier with Continental PCM |

| 2012 | Pilot | 2WD | 5FNYF3H..CB029004 and later with Keihin PCM |

| 2012 | Pilot | 4WD | 5FNYF4H..CB058214 and later with Keihin PCM |

| 2013–15 | Pilot | ALL | ALL with Keihin PCM |

REVISION SUMMARY

Under WARRANTY CLAIM INFORMATION, a failed part number (FPN) was changed.

SYMPTOM

Under certain driving conditions, there is excessive vibration between 30 and 65 mph.

POSSIBLE CAUSES

For 2WD and 4WD vehicles, the calibration VCM operation combined with the action of the lock up torque converter creates excessive vibration.

Additionally for 4WD vehicles, the propeller shaft’s center support bearing bushing material may not effectively dampen vibrations in cold (below 32ºF) temperatures.

CORRECTIVE ACTION

Do the inspection procedure, and based on your results, you may need to update the PCM. For 4WD vehicles, you may also need to replace the propeller shaft.

SOFTWARE INFORMATION

NOTE: Unnecessary or incorrect repairs resulting from a failure to update the HDS or MVCI are not covered under warranty.

MVCI Control Module (CM) Update:

Application Version 3.001.040 or later

Database update 17-March-2015 or later

HDS Software Version:

3.016.018 or later

Before beginning the repair, make sure that both the HDS and MVCI are updated as listed above. Do only the update listed in this service bulletin.

Check that the MVCI indicates the applicable program ID listed below (or a later program ID) as the Available Update when the update begins.

If the MVCI displays This vehicle does not need an update at this time during the update, the software for this service bulletin is already installed.

For more information about updating the HDS, the MVCI, and vehicle systems, refer to Service Bulletin 01-023, Updating Control Units/Modules.

KEIHN PCM

| Year/Model | PGM-FI Program ID (or later) | PGM-FI Program P/N (or later) | A/T Program ID (or later) | A/T Program P/N (or later) | System to Update |

| 2012 Pilot 2WD | N0A070 | 37805-RN0-A07 | N0A030 | 37806-RNO-A03 | PGM-FI and A/T |

| 2012 Pilot 4WD | N0A970 | 37805-RN0-A97 | N0A930 | 37806-RNO-A93 | PGM-FI and A/T |

| 2013 Pilot 2WD | N0M030 | 37805-RN0-M03 | N0A030 | 37806-RNO-A03 | PGM-FI and A/T |

| 2013 Pilot 4WD | N0M930 | 37805-RN0-M93 | N0A930 | 37806-RNO-A93 | PGM-FI and A/T |

| 2014 Pilot 2WD | N0M030 | 37805-RN0-M03 | N0A030 | 37806-RNO-A03 | PGM-FI and A/T |

| 2014 Pilot 4WD | N0M930 | 37805-RN0-M93 | N0A930 | 37806-RNO-A93 | PGM-FI and A/T |

| 2015 Pilot 2WD | N0M120 | 37805-RN0-M12 | N0A030 | 37806-RNO-A03 | PGM-FI and A/T |

| 2015 Pilot 4WD | N0M820 | 37805-RN0-M82 | N0A930 | 37806-RNO-A93 | PGM-FI and A/T |

*Keihin PCMs contain two chips that require you to update both the PGM-FI and A/T system software.

CONTINENTAL PCM

| Year/Model | PGM-FI Program ID (or later | PGM-FI Program P/N (or later) | System to Update |

| 2012 Pilot 2WD | N0B250 | 37805-RN0-B25 | PGM-FI |

| 2012 Pilot 4WD | N0B350 | 37805-RN0-B35 | PGM-FI |

For more information about Keihin and Continental PCMs and how they are different, refer to the ServiceNews article

“New PCM Supplier for Odysseys and Pilots.”

PARTS INFORMATION

| Part Name | Part Number | Quantity |

| Bolt Washer | 90382-SZA-003 | 2 |

| Flange Bolt (10 mm x 25 mm) | 90113-S3V-A00 | 8 |

| Propeller Shaft (for 4WD) | 40100-SZA-S01 | 1 |

WARRANTY CLAIM INFORMATION

The normal warranty applies.

Software Update Only

| Operation Number | Description | Flat Rate Time | Template ID | Failed Part Number |

| 2200A0 | REPAIR PROCEDURE A:

For 2WD vehicles: Update the PCM (includes test-drive and diagnosis). | 0.8 hr | 14-078A | 37820-RN0-A95 |

| REPAIR PROCEDURE B:

For 4WD vehicles: Update the PCM (includes test-drive and diagnosis). | 0.8 hr | 14-078B | 37820-RN0-A95 |

Defect Code: 08001

Symptom Code: 04201

Skill Level: Repair Technician

Software Update and Propeller Shaft Replacement

| Operation Number | Description | Flat Rate Time | Template ID | Failed Part Number |

| 2200A0 | REPAIR PROCEDURE B:

For 4WD vehicles: Update the PCM (includes test-drive and diagnosis). | 0.8 hr | 14-078C | 40100-SZA-A02 |

| 2191A8 | REPAIR PROCEDURE C: For 4WD vehicles: Replace the propeller shaft. | 0.4 hr |

Defect Code: 08001

Symptom Code: 04201

Skill Level: Repair Technician Propeller Shaft Replacement Only

| Operation Number | Description | Flat Rate Time | Template ID | Failed Part Number |

| 2191A8 | REPAIR PROCEDURE C: For 4WD vehicles: Replace the propeller shaft. | 0.4 hr | 14-078D | 40100-SZA-A02 |

Defect Code: 08001

Symptom Code: 04201

Skill Level: Repair Technician

INSPECTION PROCEDURE Customer Questions

Have the service advisor ask the customer the following questions:

- What is the outside temperature when the vibration occurs?

Above 32 ºF Below 32 ºF Temperature has no effect on vibration

- At what speed does the vibration occur?

Low speed (up to 30 MPH) Medium speed (30-65 MPH) High speed (above 65 MPH)

- Under what driving condition is the vibration occurring?

Light or steady throttle Hard Acceleration Light braking Moderate or hard braking

Test-Drive the vehicle

- Test-drive the vehicle and confirm the customer information using the HDS; set the cruise control Cancel button in the perimeter setting to trigger the snapshot. Then, set up the HDS to take a PGM-FI snapshot 15 seconds before and after the trigger.

- Drive the vehicle in the speed range where the customer feels the vibration. Once you feel the vibration, keep the throttle and speed steady and press the cruise control Cancel button once to trigger the snapshot.

- Save the snapshot.

- Repeat steps 1 through 3 a second time before going to step 5.

- Continue driving to create the vibration again. Once you feel the vibration, press the cruise control Cancel button again to trigger the snapshot, then lift off the throttle for 2 seconds, and then resume the throttle.

- If the vibration does not go away, this bulletin does not apply. Continue with normal troubleshooting.

- If the vibration goes away, continue to Results.

Results

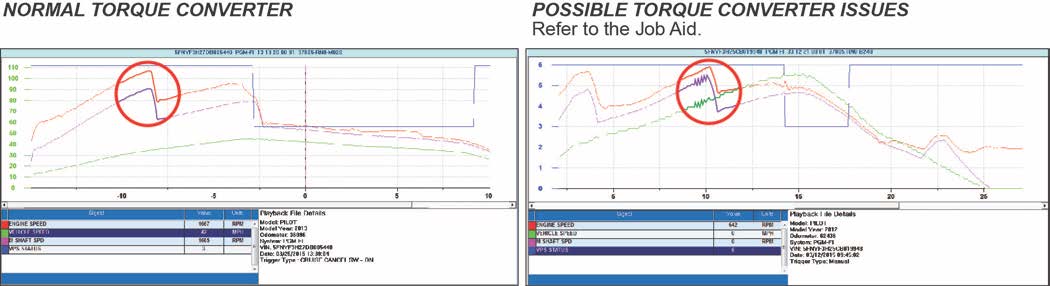

To review the snap shots, select the following signals:

- VPS Status

- Engine Speed

- M Shaft SPD

- Vehicle Speed

Set the cylinder (scale to 10).

NOTE: Setting the scaling parameters to the lowest levels will make interpreting the data easier.

This bulletin does not apply if any of the following occurred; continue with normal troubleshooting:

- The customer indicated the vibration occurred under braking or hard acceleration.

- The engine is not in valve pause when the vibration occurs.

- The snapshots 1 and 2 indicate fluctuations in the main shaft but the engine speed is steady – review the job aid Torque Converter Clutch Shudder and Vibration.

Do REPAIR PROCEDURE A (2WD) if:

- The vibration occurred between 30 and 65 mph; review the snapshots 1 and 2 to see if the snapshot shows the engine in valve pause and the main shaft and rpms are steady at the time of the vibration. Also check snapshot 3 to confirm that the engine was in valve pause once the vibration occurred and went away when you released the throttle.

- The vibration occurred between 30 and 65 mph; the vibration occurred during light or constant throttle.

Do REPAIR PROCEDURE B (4WD) if:

- The vibration occurred between 30 and 65 mph; review the snapshots 1 and 2 to see if the snapshot shows the engine in valve pause and the main shaft and rpms are steady at the time of the vibration. Also check snapshot 3 to confirm that the engine was in valve pause once the vibration occurred and went away when you released the throttle.

- The vibration occurred between 30 and 65 mph; the vibration occurred during light or constant throttle.

Do REPAIR PROCEDURE C (4WD) if:

- The customer indicated that the vibration occurs when the temperature was 32 ºF or colder, you will need to replace the propeller shaft.

REPAIR PROCEDURE A (2WD)

Update the PGM-FI and the A/T software. Refer to Service Bulletin 01-023, Updating Control Units/Modules.

REPAIR PROCEDURE B (4WD)

Update the PGM-FI or the A/T software. Refer to Service Bulletin 01-023, Updating Control Units/Modules.

- If your inspection results indicated to replace the propeller shaft, go to REPAIR PROCEDURE C. • If your inspection results did not indicate replacing the propeller shaft, the vehicle is repaired.

REPAIR PROCEDURE C (4WD)

NOTE: Make sure you update the A/T and PGM-FI software or check that the software has been updated before replacing the propeller shaft. 1. Raise and support the vehicle.

- Raise and support the vehicle.

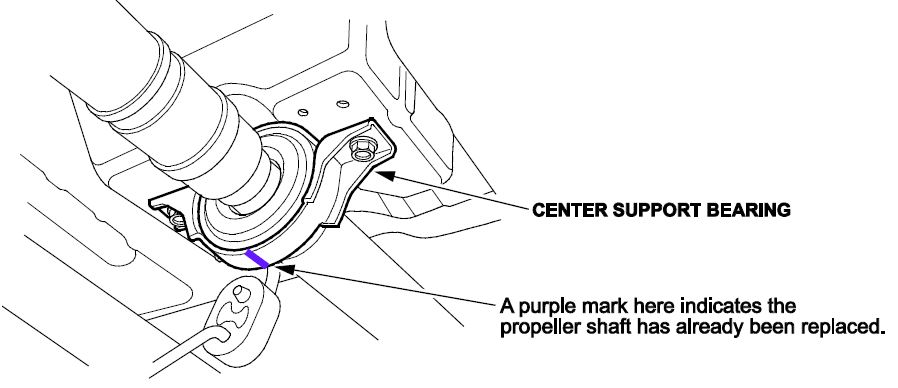

- Check that the propeller shaft has not already been replaced. Check if there is a purple mark on the center support bearing as shown below.

- If there is a purple mark on the center support bearing, the propeller shaft has already been replaced with a new part. Do not replace the propeller shaft again. If there is still a vibration, this bulletin does not apply. Continue with normal troubleshooting.

- If there is no purple mark, go to step 3.

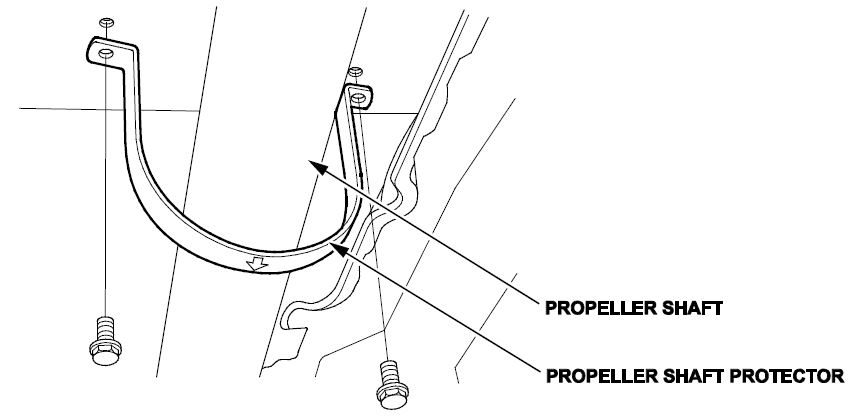

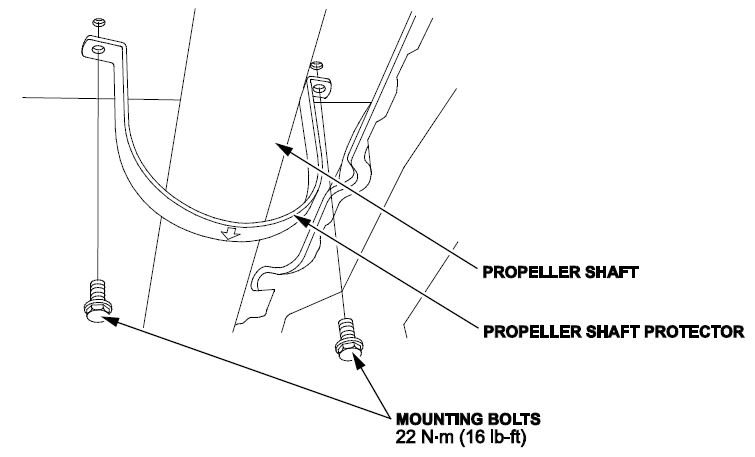

- Remove the propeller shaft protector.

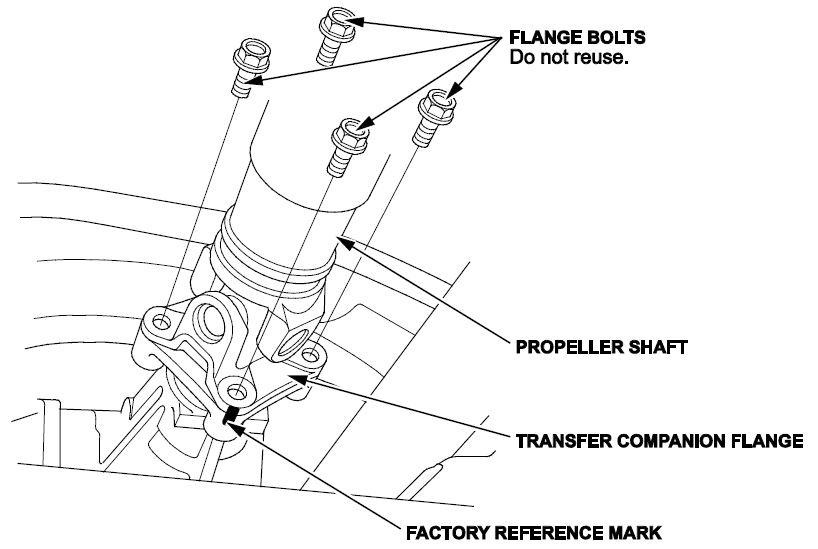

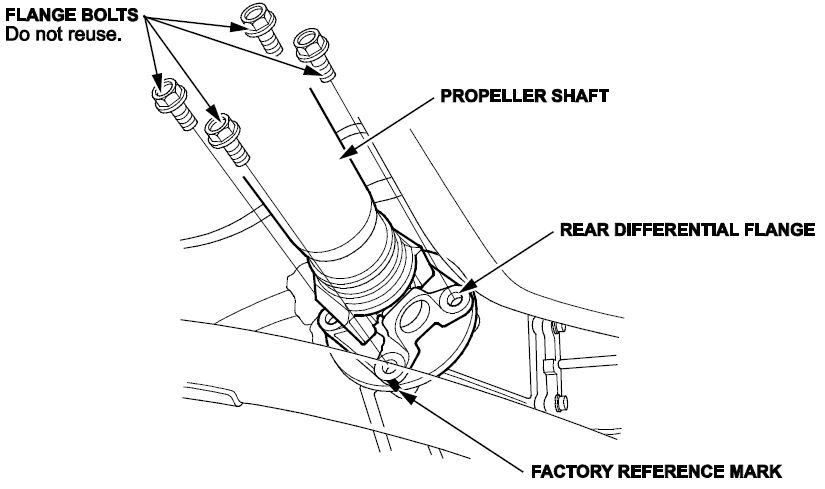

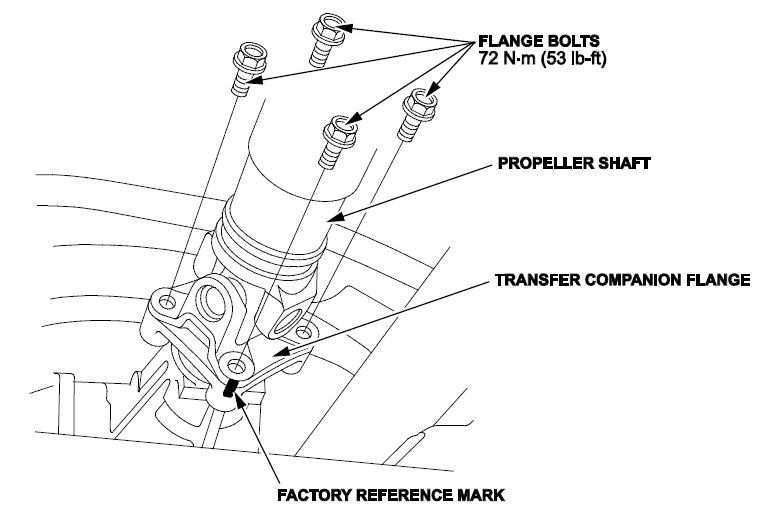

- Remove the flange bolts from the transfer companion flange.

- Remove the flange bolts from the rear differential flange.

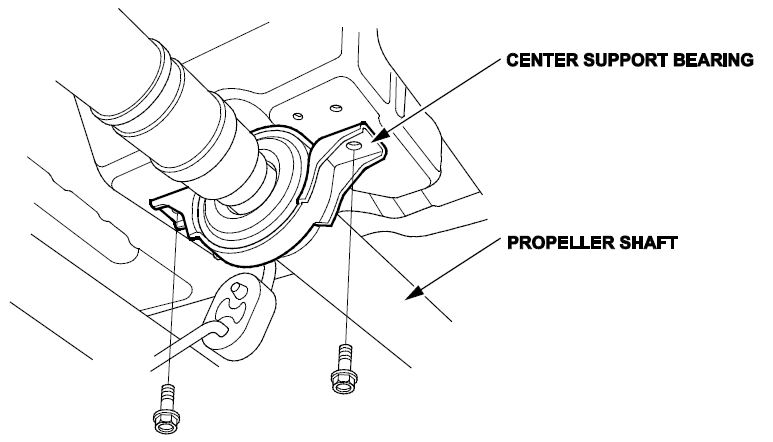

- Remove the center support bearing mounting bolts.

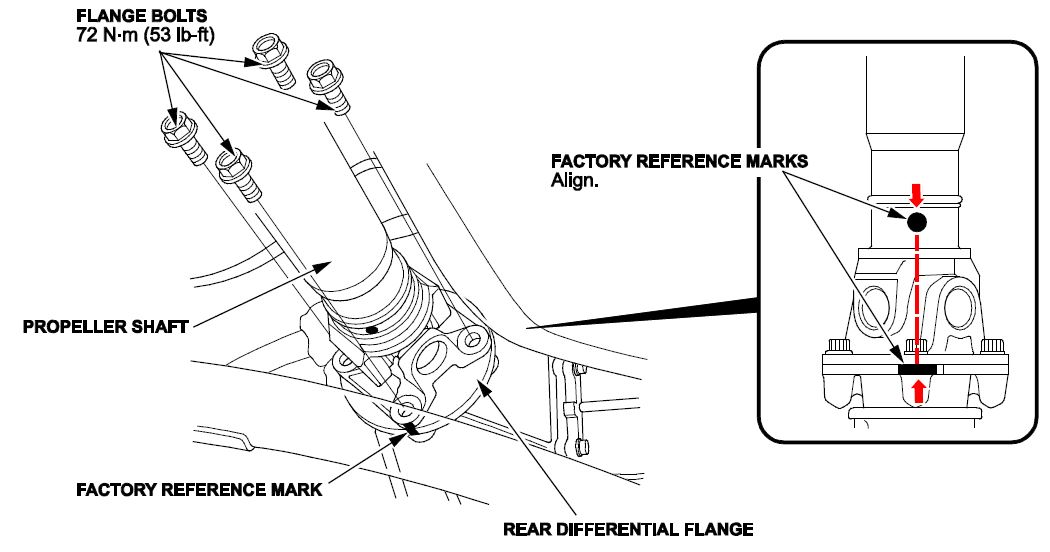

- Install the new propeller shaft by aligning the factory reference marks on the No. 2 propeller shaft to the rear differential companion flange as shown below. Then install new flange bolts and torque them to 72 N·m (53 lb-ft).

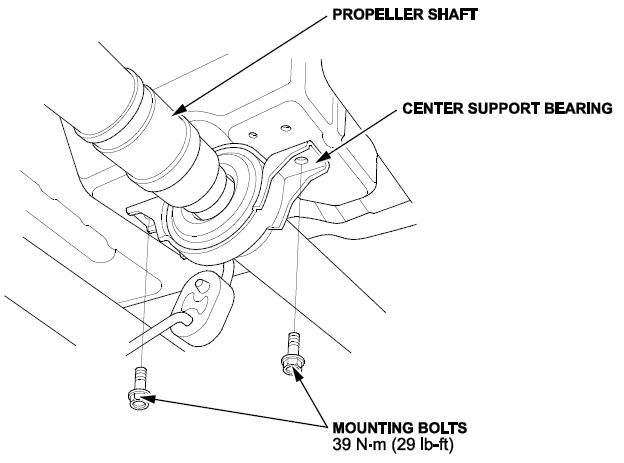

- Install the new center support bearing mounting bolts and torque them to 39 N·m (29 lb-ft).

- Set the No. 1 propeller shaft to the transfer companion flange. Then install new flange bolts and torque them to 72 N·m (53 lb-ft).

- Reinstall the propeller shaft protector.

END

Loading...

Loading...

Reprogramming

i-HDS Diagnostic Software and J2534 Reprogramming Software

Honda J2534 Pass-Thru User Guide

Honda J2534 Pass-Thru Software Download

i-HDS Diagnostic Software and J2534 Reprogramming Software

American Honda Motor Co., Inc. ("Honda

Motor Co., Inc. ("Honda ") offers the i-HDS (Honda

") offers the i-HDS (Honda Diagnostic System) software suite for the diagnosis and repair of electronic systems on Honda

Diagnostic System) software suite for the diagnosis and repair of electronic systems on Honda and Acura

and Acura automobiles, and for the reprogramming of electronic control units (including, but not limited to, ECMs and PCMs). This software provides access to all Honda

automobiles, and for the reprogramming of electronic control units (including, but not limited to, ECMs and PCMs). This software provides access to all Honda and Acura

and Acura vehicle systems (access to the immobilizer security system requires a Security Professional level software subscription and Vehicle Security Professional [VSP] registration with NASTF). To use the i-HDS software, you need to purchase one of our convenient subscription options. In addition, you will need a pass-thru Vehicle Communication Device (VCI) that is compliant with SAE J2534-1 and J2534-2 in order to communicate with the vehicle

vehicle systems (access to the immobilizer security system requires a Security Professional level software subscription and Vehicle Security Professional [VSP] registration with NASTF). To use the i-HDS software, you need to purchase one of our convenient subscription options. In addition, you will need a pass-thru Vehicle Communication Device (VCI) that is compliant with SAE J2534-1 and J2534-2 in order to communicate with the vehicle

Vehicle Communication Interfaces (VCI)

The i-HDS software supports the use of a generic pass-thru VCI that is compliant with SAE J2534-1 and J2534-2. However, Honda recommends the Denso DST-i or the Bosch MVCI for use on Honda

recommends the Denso DST-i or the Bosch MVCI for use on Honda and Acura

and Acura vehicles, as Honda

vehicles, as Honda has worked closely with these manufacturers to ensure their hardware and our software interact safely and within the J2534-1 and -2 specifications, for both diagnostics and reprogramming. If you choose to use a generic VCI, please carefully consider the customer and technical support options you will receive from your chosen device supplier. Honda

has worked closely with these manufacturers to ensure their hardware and our software interact safely and within the J2534-1 and -2 specifications, for both diagnostics and reprogramming. If you choose to use a generic VCI, please carefully consider the customer and technical support options you will receive from your chosen device supplier. Honda does not provide technical or customer support for generic VCI devices.

does not provide technical or customer support for generic VCI devices.

The VCI Application Table below lists devices that either are approved and supported by Honda or are known to have completed and passed an independent, exhaustive validation program with our i-HDS software suite.

or are known to have completed and passed an independent, exhaustive validation program with our i-HDS software suite.

| VCI Name | Manufacturer | Version Information | Notes | |

|---|---|---|---|---|

| Firmware | J2534 API | |||

| DST-i | DENSO | 2.02.0002* | 04.04 | This is the current generation VCI used by Honda and Acura and Acura dealers. Honda dealers. Honda routinely validates the functionality and provides customer support for this device. routinely validates the functionality and provides customer support for this device. |

| DST-nano | DENSO | 2.02.0002* | 04.04 | This is the current generation VCI used by Honda Canada Inc. Honda Canada Inc. Honda and Acura and Acura dealers. Honda dealers. Honda routinely validates the functionality and provides customer support for this device. routinely validates the functionality and provides customer support for this device. |

| MVCI | Bosch | 3.01.60* | 04.04 | This is the previous generation VCI used by Honda and Acura and Acura dealers. Honda dealers. Honda routinely validates the functionality and provides customer support for this device. routinely validates the functionality and provides customer support for this device. |

| MongoosePro Honda |

Drew Technologies | 1.9.5** | 04.04 | This company has completed an independent i-HDS validation and claims it to function with the i-HDS software. Honda does not provide ongoing validation, nor customer support for this device. does not provide ongoing validation, nor customer support for this device. |

| d-briDGe Pro | Dearborn Group | 3.303** | 04.04 | This company has completed an independent i-HDS validation and claims it to function with the i-HDS software. Honda does not provide ongoing validation, nor customer support for this device. does not provide ongoing validation, nor customer support for this device. |

* These versions may have been superseded. Honda provides the latest supported versions to current i-HDS subscribers.

provides the latest supported versions to current i-HDS subscribers.

** Version used in validation program. See Terms and Conditions and Important Notice Regarding Reprogramming below for more details.

Reprogramming with the J2534 Rewrite Application in i-HDS

Included in the i-HDS software suite is a new reprogramming application called J2534 Rewrite. This application is made available to all subscribers of the i-HDS software suite and replaces the previous generation software, J2534 Honda Pass-thru Reprogramming Software.

Pass-thru Reprogramming Software.

This new application is compatible with generic VCIs that comply with SAE J2534. It must be used to reprogram any Honda /Acura

/Acura vehicle equipped with ECUs that support reprogramming. Refer to the table below for legacy applicability for the programming of ECMs and PCMs. Though system dependent, late-model vehicles may be equipped with other ECUs that support reprogramming as well, e.g. ABS or VSA. J2534 Rewrite must be used to reprogram these control modules, as instructed in an applicable service bulletin.

vehicle equipped with ECUs that support reprogramming. Refer to the table below for legacy applicability for the programming of ECMs and PCMs. Though system dependent, late-model vehicles may be equipped with other ECUs that support reprogramming as well, e.g. ABS or VSA. J2534 Rewrite must be used to reprogram these control modules, as instructed in an applicable service bulletin.

As shown in this table, not all legacy Honda /Acura

/Acura models are equipped with a reprogrammable ECM/PCM. Furthermore, all 2007 and later models not listed in the table are fully supported with this application.

models are equipped with a reprogrammable ECM/PCM. Furthermore, all 2007 and later models not listed in the table are fully supported with this application.

DST-i Information:

MVCI Information:

- J2534 Pass-Thru Programmer: TOPDON RLink J2534 is an advanced diagnostic and reprogramming tool that support all J2534 protocols, as well as D-PDU, CAN-FD and DoIP, ensuring compatibility with a wide range of modern vehicles. It offers extensive versatility with support for over 17 major automotive brands, including Chrysler, Ford, GM, Nissan, Toyota

, Honda

, Honda , Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen

, Subaru, Land Rover/Jaguar, Volvo, Wuling, Volkswagen , Mercedes-Benz, and BMW

, Mercedes-Benz, and BMW , and so on, enjoy dealership-level functions at your fingertips

, and so on, enjoy dealership-level functions at your fingertips - All-in-One OEM Diagnostics: This J2534 ECU programming tool elevates your automotive repair capabilities to new heights by delivering complete OEM diagnosis. Boasting comprehensive full-system diagnostics, intuitive repair guides, advanced ECU programming and coding, common reset services, a vast library of repair information and more, this all-in-one solution empowers technicians to effortlessly tackle complex vehicle issues with ease

- Proven Performance You Can Trust: Backed by over 10000 real vehicle tests and benefit from a wealth of practical experience, this OEM reprogramming tool guarantees stable and exceptional performance. Supported by TOPDON's dedicated technical experts with in-depth knowledge of both auto repair and J2534 Pass-Thru programming, the RLink J2534 provides prompt and professional assistance, ensuring a smooth setup and reliable compatibility

- Integrated Excellence, Always Up-to-Date: Featuring the exclusive RLink Platform to provide a streamlined experience with one-click driver installation and management, ensuring flawless integration with your OE software, maintaining the original performance quality. The built-in operation guide makes mastering OE software quick and easy, so you can get started right away. Plus, with lifetime free updates, your diagnostics will stay current with the latest drivers and innovations

- Efficiency Meets Versatility: Engineered to support three CAN channels simultaneously - CAN FD and CAN-CC included, giving you the edge in fast troubleshooting. To perfectly synchronized with the OE software, please diagnose with active subscriptions and make sure your computer system is running a compatible 64-bit Windows version (7, 8, 10 or later) to fully leverage the power of RLink J2534. *We don't provide extra OE software

- 【J2534 PROTOCOL WITH SMARTLINKC】 LAUNCH X431 PRO3S+ ELITE scan tool with newly upgraded smartlinkC V2.0. The SmartLinkC is a communication interface supporting J2534 specifications. Of course, it also can be used as a J2534 PassThru device, working together with the PC installed with the OEM diagnostic software to perform the J2534 protocol.J2534 protocol is the only solution for problems ranging from driveability and loss of power to poor fuel economy.

- 【INTELLIGENT TOPOLOGY MAP TO FASTER FULL SYSTEMS DIAGNOSIS】 X431 PRO3S+ELITE bidirectional scan tool with new-added intuitive topology mapping. Harnesses intuitive topology mapping for comprehensive visualization of the vehicle all system. It shows all available control units in different colors, the numbers of system, the scanned system, and the scan results, bringing maximum convenience & superfast speed for you to do swift diagnosis & high-level repairs.

- 【TOP HARDWARE CONFIGURATION, UPGRADED OF LAUNCH X431 PRO3S+】 LAUNCH X431 PRO3S+ELITE diagnostic scanner possess with Android 10.0 OS; CPU 4-Core Processor, 2.0 GHz. Greatly increased the speed of running multiple task. 2.4GHz/5GHz; 6300mAh/7.6V stronger battery capacity; 10.1 Inch Touchscreen with 8MP camera; AUTO VIN; 4GB+64GB storage memory; 20X faster transmission rate, save more vehicle documents and customer data; Supports 25+ Software Languages, such as EN, DE, FR, SP nd JP and so on.

- 【3000+ ACTIVE TEST/BI-DIRECTIONAL CONTROL LAUNCH SCANNER】 LAUNCH X431 PRO3S+ELITE HD automotive scanner is a cost-effective bidirectional scanner that deserves owned by every repairing DIYers and mechanics. You can easily send command signal at fingertips from the scanner to various module actuators to test component integrity and functionality in minutes or even seconds to tell if replacement or repair is needed.

- 【COMPLETE 60+ HOT RESETS, CALIBRATION, INITIALIZATION, RELEARN】 LAUNCH X431 PRO3S+ELITE SmartLinkC escaner automotriz professional enjoys 60+ special service, such as Oil Reset, ABS brake bleed, EPB, SAS, BMS, Suspension, Injector reset, Power Balance, Turbo Calibration, VGT, Transmission Adaption, Throttle Adaptation, matching and etc. rigorous on-site testing has been performed to ensure 100% availability.

- ALL OF THE J2534 PROTOCOLS - This single unit has all of the protocols you need for your OEM J2534 reprogramming and diagnostics including the latest in DoIP and CanFD

- J2534 TECHNICAL SUPPORT - FREE for the life of the tool. Staffed by technicians who understand vehicle repair and J2534 Pass‑thru

- TOOLBOX WITH OEM APPLICATION DESCRIPTIONS - educational video tutorials and real-time news – Giving you the confidence and up-to-date knowledge to get the job done

- J2534 v05.00 API - The newest version of J2534 to give you the latest in pass-thru technology

- FUTURE PROOF WITH 4 CAN CHANNELS - Going beyond the 3 required by select Chrysler/FCA models, CarDAQ-Plus 3 also provides a 4th to meet the needs of future OEM applications

- 🌐【Works with Autel Elite II Elite MS908 MS908S Pro II MS908CV II MK908P MK908 Pro II】Autel J2534 work with these tools to program ECUs on specific BM.W/ BE.NZ for specific functions. ★★NOTE: J2534 CANNOT directly work with these single devices. After you received the J2534, you HAVE TO send us both the S/N(12 digits) of your scanner MS908S(etc.) and J2534. So, technically, Autel engineers can help you bind J2534 with your devices. If need any supports, contact us via: 🚘auteldirect @ outlook. com🚘.

- 🌐【SAE J2534-1 & J2534-2 Standards】Autel MaxiFlash Elite J2534 is a fully compliant SAE J2534-1 & SAE J2534-2 (March 2006) device, which performs standard PassThru J2534 functionality: Compatible with for Toyota

Techstream, Volvo VIDA, Honda

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility.

HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility. - 🌐【High-speed Transmission Speed】Autel MaxiFlash Elite Reprogramming Device J2534 supports simultaneous communication definition in J2534-1, running 3 protocols at the same time, which greatly improves reprogramming and diagnostic speed. Embedded with the ARM9 Dual-core processor (clocked up to 500MHz), which further boosts the communicating speed to save more times and win more business.

- 🌐【Multiple Devices Connected with P-C】Autel MaxiFlash Elite J2534 also supports multiple device connections to the P-C, which can operate diagnostic and reprogramming functions on more than one vehicle at the same time. Autel MaxiFlash Elite J2534 built-in wireless and data storage, which can update via Internet. It also ensures quickly reprogramming even the newest controllers.

- 🌐【Extensive Compatibility】Autel MaxiFlash J2534 is compatible with Toyota

Techstream, Volvo VIDA, Honda

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

- CUSTOM-DESIGNED FOR USE WITH FORSCAN: Works with all FORScan compatible vehicles and is recommended by the FORScan Team

- DEALERSHIP-LEVEL DIAGNOSTICS: OBDLink EX supports all Ford protocols, modules, and advanced features of FORScan

- ELECTRONIC SWITCH allows FORScan to access all CAN buses simultaneously and enables advanced functions not possible with “toggle switch” adapters

- MAXIMUM THROUGHPUT -- up to 20 times faster than “toggle switch” adapters

- ROCK-SOLID CONNECTION avoids data corruption and dropped packets

- 🌎【Autel All-in-1 Reprogramming Tool】As an OEM Vehicle interface for multiple makes, Autel J2534 pass-thru programmer is a multi-functional programming and communication device. Work with Autel MS909 Ultra Lite Elite 2 Pro MS909 MS909CV MS909EV to directly program on Merce.des-Be.nz & BM.W. Autel MaxiFlash VCI also works with P-C to download OEM vehicle software, seamlessly conduct OE-level diagnostic-programming-coding. Enhanced multi-protocol: SAE J2534/ CAN FD/ DoIP/ D-PDU/ RP1210, Autel Maxiflash VCI J2534 is a must have aftermarket programming device for any mechanic/ technician in the programming wo.rld!

- 📢【Kind Tips】After purchasing the J2534, you need to update the firmware first. Steps: ✅𝟭. Access to Autel official website > click "Support" - "Download" > download "Maxi P-C Suite" APP ✅𝟮. connect J2534 and compu-ter via USB Cable ✅𝟯. Install "Maxi P-C Suite" APP on the compu-ter and update to the latest version > go to the vehicle website to purchase the corresponding OEM software for use. 📢Note: J2534 is only compatible with Windows compu-ters, and OEM software needs to be purchased.

- 🌎【Compatible with Autel Elite II Pro Ultra Lite MS909 MS909CV MS909EV & P-C/ WIND.OWS】This 2025 latest Autel J2534 Pass-Thru VCI is 100% compatible with Autel Elite II Pro Ultra Lite MS909 MS909CV MS909EV to perform advanced functions from diagnose to programming. Besides, it can connect to P-C with Easy Steps: 1) Connect to P-C via a USB cable 2) download OEM vehicle software 3) Start Diagnose. Take For.d for example, you can download OEM software on mot.orcraft.erservi.ce website, such as: For.d Diagnostic Software downloads, As B.uilt Data, Updated Cali.bration information, then use different software do relevant features.

- 🌎【Enhanced Protocol: CAN FD/DoIP/D-PDU/RP1210/J2534】Autel MaxiFlash JVCI is a blueto.oth communicate device, it supports latest CAN FD DoIP CAN protocols, compliant with automotive D-PDU/ J2534/ RP1210 standards. It can perform standard PassThru J2534 functions: compatible with Toyota

Techstream, Volvo VIDA, Honda

Techstream, Volvo VIDA, Honda HDS, Jaguar Land Rover IDS and BM.W 3G for OEM diagnostics. CAN FD protocol is mainly for GM 2019+, DoIP protocol is mainly for Volvo 2018+, for L-and Rover/for Jaguar 2017+, for BM.W F chassis and G chassis.

HDS, Jaguar Land Rover IDS and BM.W 3G for OEM diagnostics. CAN FD protocol is mainly for GM 2019+, DoIP protocol is mainly for Volvo 2018+, for L-and Rover/for Jaguar 2017+, for BM.W F chassis and G chassis. - 🌎【ECU Programming Coding】Tailored to ECU programming & coding, Autel J2534 Pass-Thru VCI can communicate effectively with the ECU across different vehicle makes and models. After you purchased OEM software, J2534 pass thru programmer can work with P-C: Update vehicle software to the latest version, optimize the histo.rical le.gacy of the car's old version, Replace existing software/ firmware, reprogram component after replacement.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.