| “This site contains affiliate links for which OEMDTC may be compensated” |

B10-004

February 10, 2010

Applies To: 2002–06 RSX – ALL

Clunk and/or Vibration When Accelerating, Decelerating, or Shifting Gears

SYMPTOM

There is a clunk and/or excessive vibration while accelerating, decelerating, or shifting gears.

PROBABLE CAUSE

The side engine mount may have been misaligned, causing it to break.

CORRECTIVE ACTION

Replace the side engine mount, and properly align it.

PARTS INFORMATION

| Engine Side Mount: P/N | 50820-S6M-023 |

| Flange Bolt, 10 x 20 (three required): P/N | 90163-S5A-000 |

WARRANTY CLAIM INFORMATION

The normal warranty applies.

| OP# | Description | FRT |

| E | Replace side engine mount.

Adjust engine mount. | 0.3 |

| 0.8 |

Failed Part: P/N 50820-S6M-023

Defect Code: 07404

Symptom Code: 04504

Skill Level: Repair Technician

REPAIR PROCEDURE

- Remove the intake manifold cover.

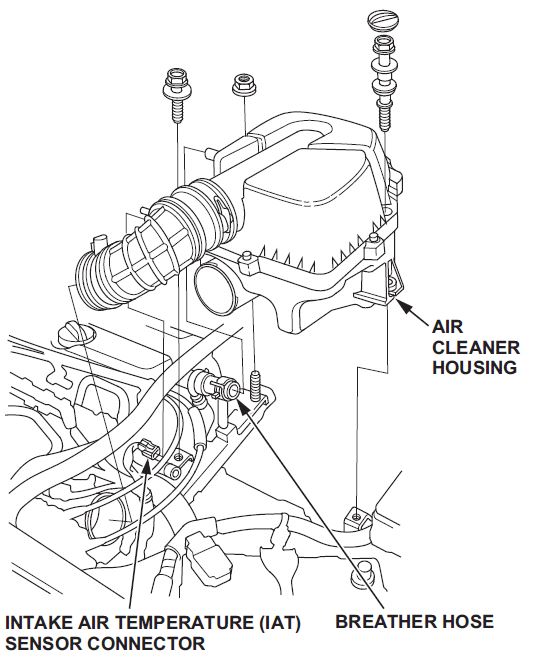

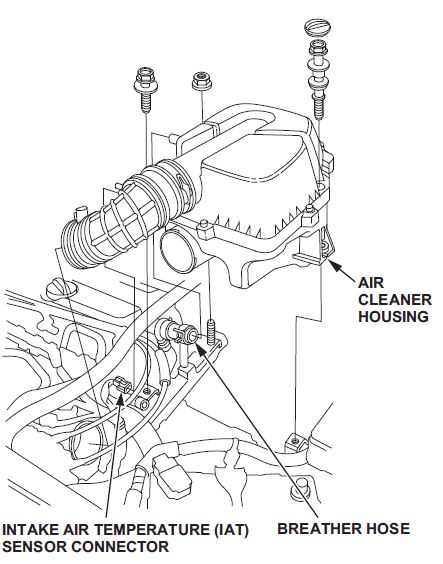

- Disconnect the intake air temperature (IAT) sensor connector, remove the breather hose, then remove the air cleaner housing.

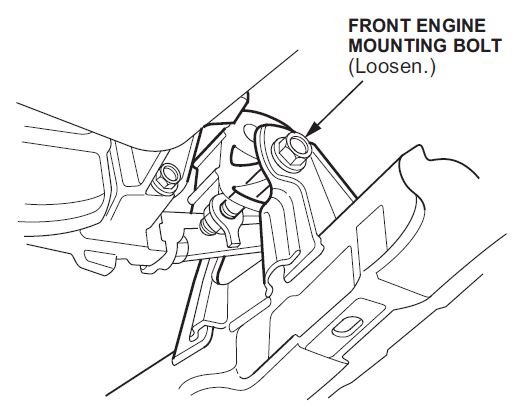

- Loosen the front engine mount bolt about 4 mm.

- Lower the vehicle.

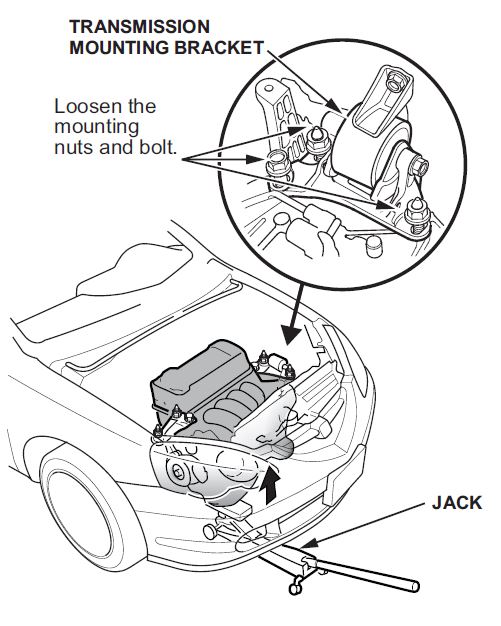

- Place a jack with a block of wood under the engine. Loosen the transmission mounting bracket bolt and nuts about 4 mm.

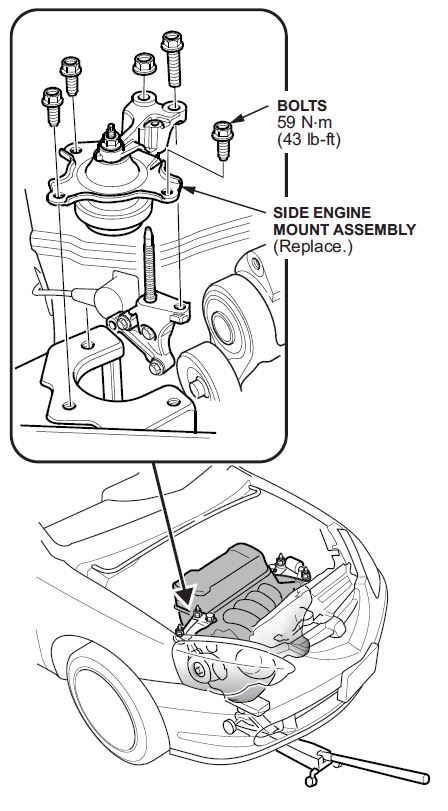

- While supporting the engine with a jack (making sure the engine is up against the mount), replace the side engine mount and its three mounting bolts.

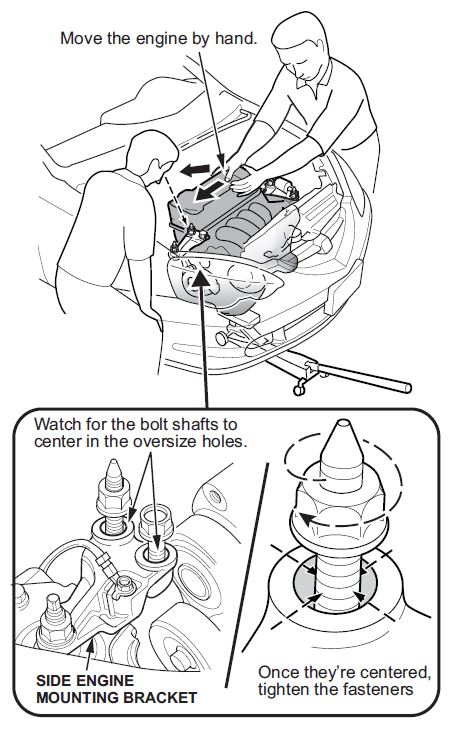

- Move the engine (not the bracket) in the directions of the arrows to center the bolt and nut in the oversized bolt holes of the side engine mounting bracket. Torque the bolt and the nut to 54 N.m (40 lb-ft).

NOTE: Two people may be needed, one to move the engine, and the other to observe the alignment and tighten the fasteners.

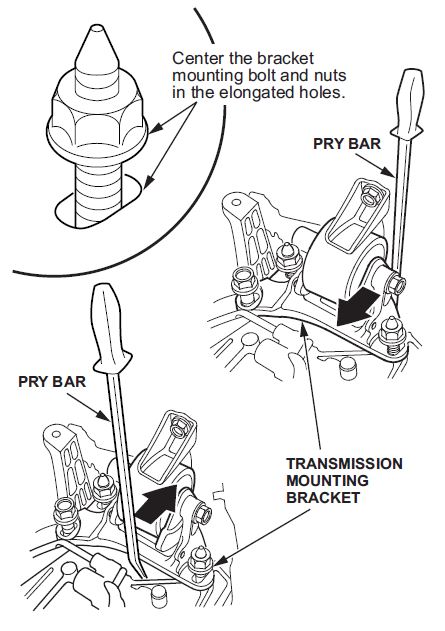

- With the jack still under the engine, place a pry bar against the transmission mounting bracket, and move the bracket in the direction of the arrow until the oversized hole is covered by the centered bolt and nut, then torque the bolt to 54 N.m (40 lb-ft).

- Remove the jack, then raise the vehicle on the lift.

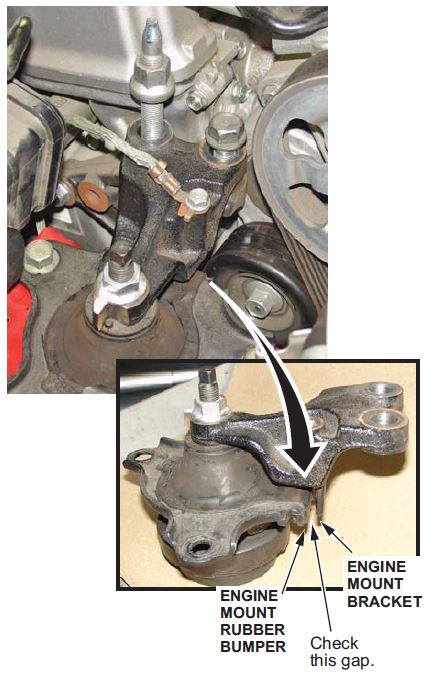

- Check for a gap of 4 mm (± 2 mm) between the metal tab of the engine mount bracket and the engine mount rubber bumper. Repeat step 10 if the clearance is not within the parameters.

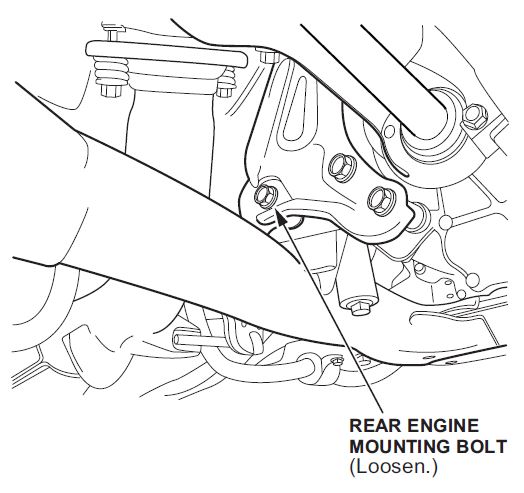

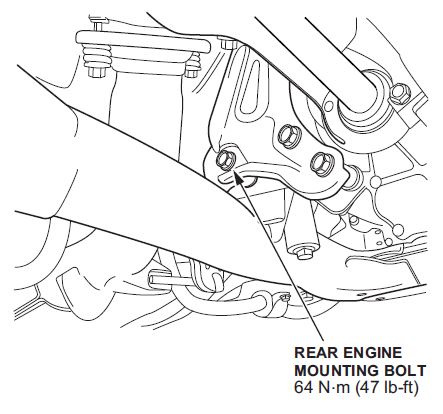

- Tighten the rear mounting bolt.

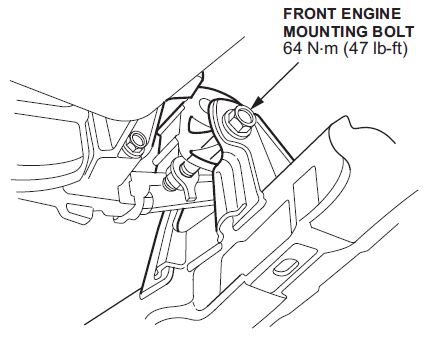

- Tighten the front mounting bolt.

- Lower the vehicle.

- Reinstall the air cleaner housing and the breather hose, then reconnect the IAT sensor connector.

- Reinstall the intake manifold cover.

Loading...

Loading...