| “This site contains affiliate links for which OEMDTC may be compensated” |

A14-047

August 2, 2014

ATB 51986 (1408)

Noise From the Rear Differential

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2012-14 | CR-V | AWD Only | ALL |

SYMPTOM

There is a creak or groan from the rear differential upon light acceleration from a stop.

POSSIBLE CAUSES

The electric oil pump motor on the rear differential has too much internal clearance.

CORRECTIVE ACTION

Replace the rear differential pump motor.

PARTS INFORMATION

| Part Name | Part Number | Quantity |

| Rear Differential Pump Motor Kit (includes O-ring and intermediate drive joint) | 41013-R7L-000 | 1 |

REQUIRED MATERIAL

| Part Name | Part Number | Quantity |

| Hard Wall PVC Tubing: 12 inch length, ½ inch ID and 5/8 inch OD, 1/16 inch wall thickness.(commercially available, McMaster-Carr) | 53945K15 | 1 |

WARRANTY CLAIM INFORMATION

The normal warranty applies.

| Operation Number | Description | Flat Rate Time | Template ID | Failed Part Number |

| 2191X1 | Replace rear differential pump motor. | 0.4 hour | 14-047A | 48900-R7L-033 |

Defect Code: 06201

Symptom Code: 04216

Skill Level: Repair Technician

DIAGNOSIS

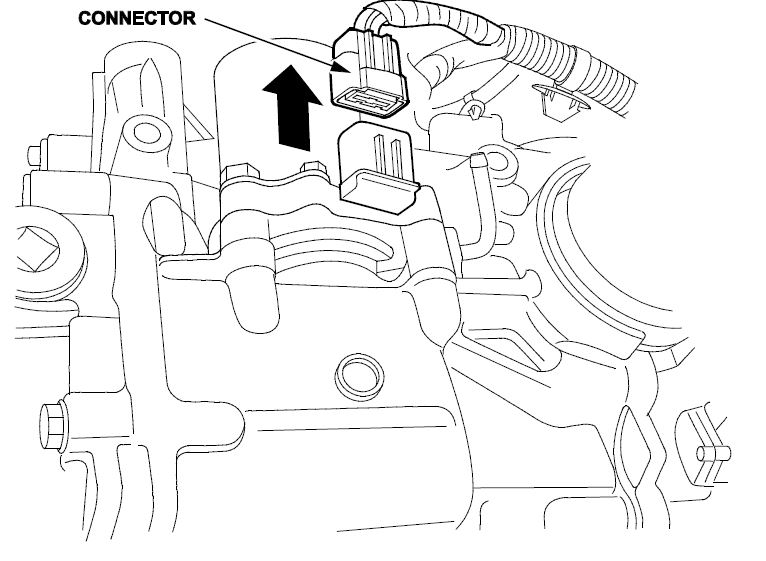

- Raise the vehicle on a lift, then disconnect the rear differential oil pump motor 2P connector.

- Lower the vehicle.

- Start the vehicle. Apply the brake pedal, put the transmission in gear, and listen for the noise as soon as you release the brake.

- If there is no noise, go to REPAIR PROCEDURE.

- If the noise is still present, this bulletin does not apply. Continue with normal troubleshooting.

REPAIR PROCEDURE

- Raise the vehicle on a lift.

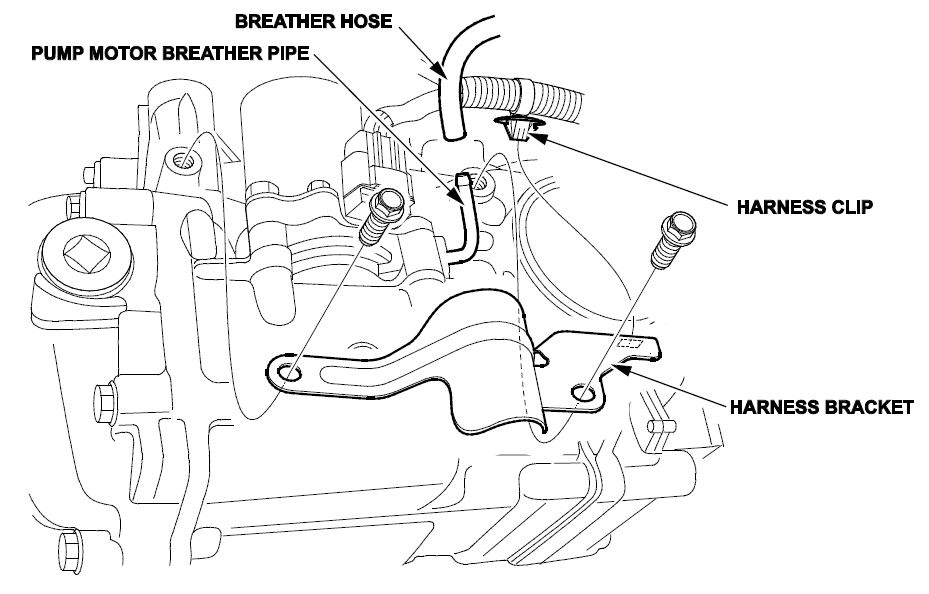

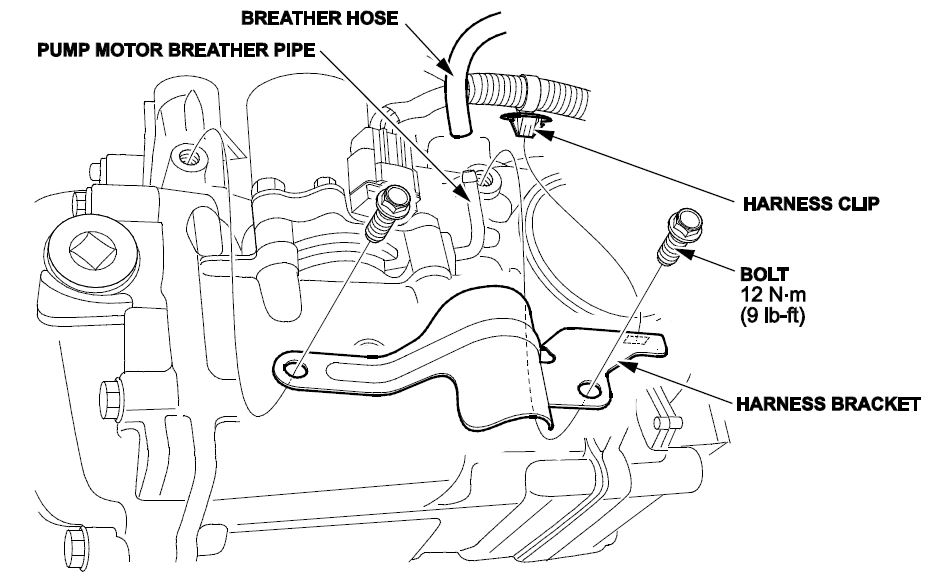

- Disconnect the breather hose from the pump motor breather pipe.

- Remove the harness clip and the harness bracket.

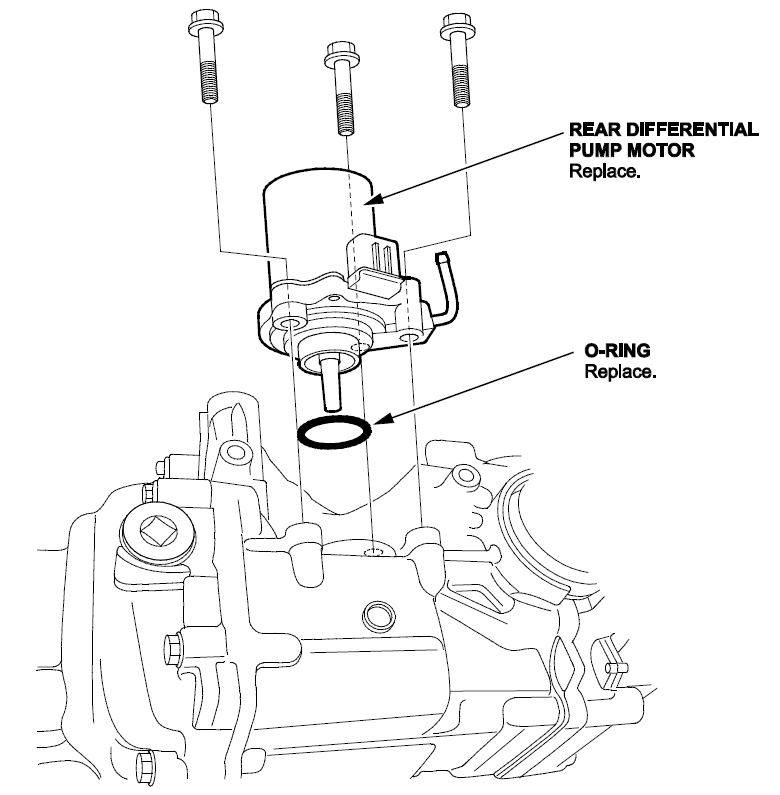

- Remove the rear differential pump motor and the O-ring.

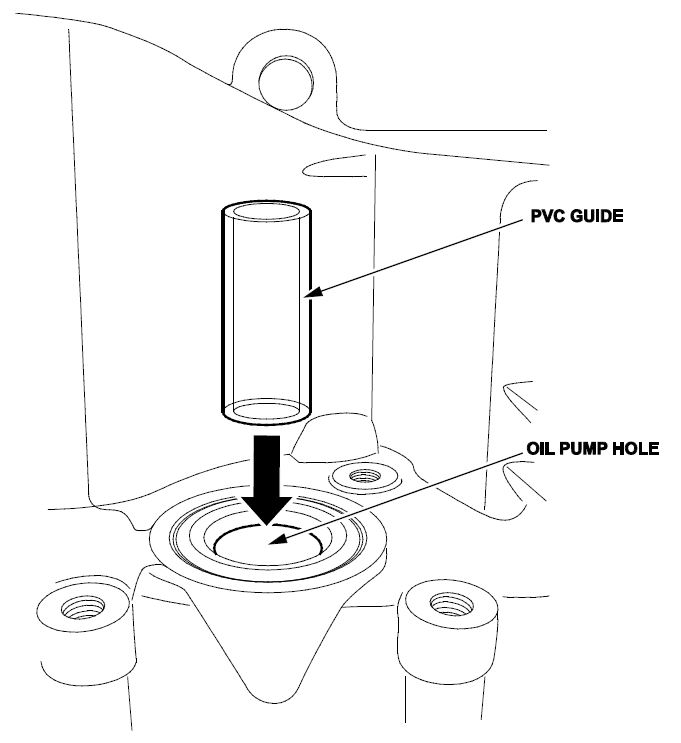

- Cut a 1 ¾ inch length of the hard wall clear PVC tubing and chamfer the newly cut edges.

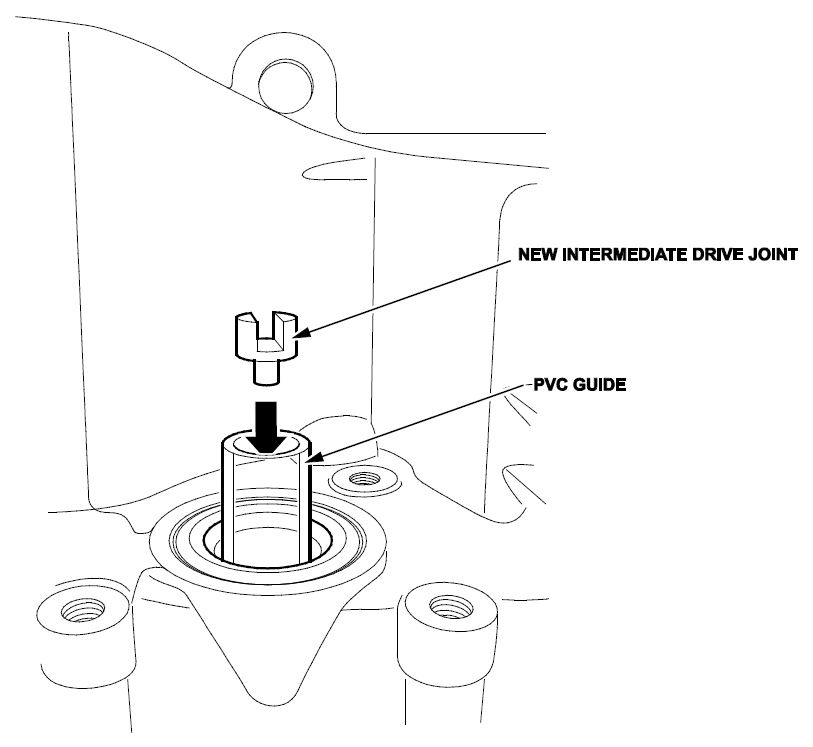

NOTE: The tubing will be used as a guide to install the new intermediate oil pump drive joint and prevent it from falling into the differential assembly where it cannot be removed.

- Insert the hard wall PVC tube guide you just cut into the oil pump hole and center it over the internal oil pump drive shaft.

- Insert the new intermediate drive joint into the PVC guide as shown.

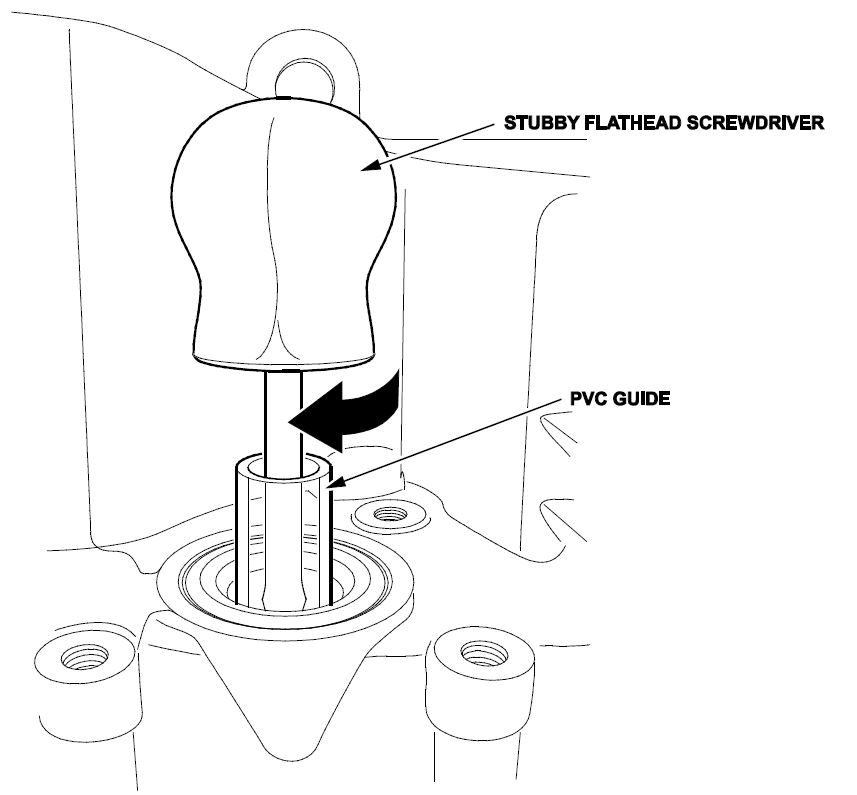

- With the PVC guide still in place, use a stubby flathead screwdriver to rotate the intermediate drive joint until it fully engages into the internal oil pump drive shaft.

- Carefully remove the guide from the oil pump hole by slowly pulling it straight out.

NOTE: If the intermediate drive joint pulls out of place, it may fall into an area where it cannot be removed without additional differential disassembly.

- Use a small telescoping mirror to verify that the new intermediate drive joint is still in place.

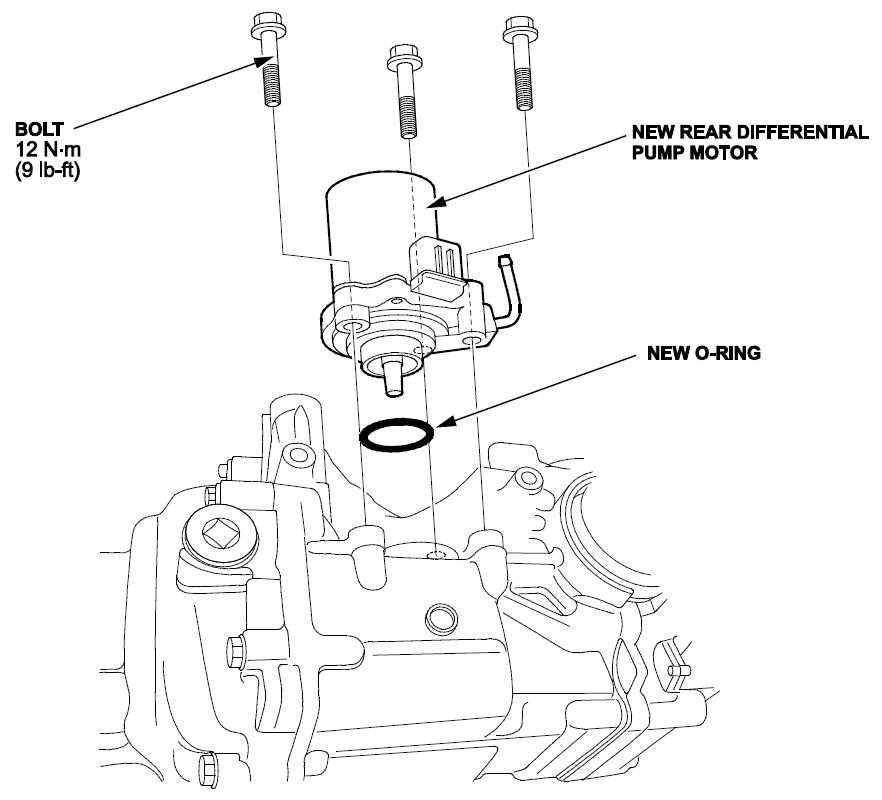

- Align the pump shaft to the new intermediate drive joint. Then install the new rear differential pump motor with a new O-ring and torque the bolts to 12 N∙m (9 lb-ft).

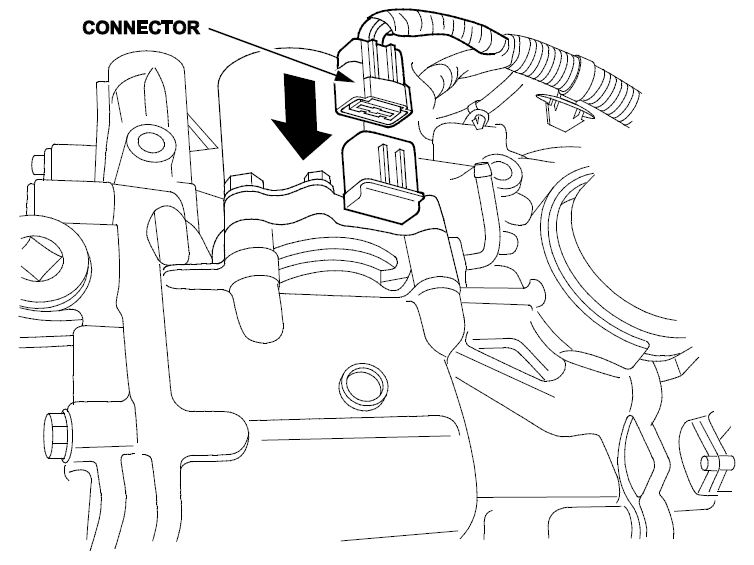

- Connect the connector.

- Install the harness bracket and torque the bolts to 12 N∙m (9 lb-ft). Then install the harness clip.

- Connect the breather hose to the pump motor breather pipe.

END

Loading...

Loading...