| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10084521

Manufacturer Communication Number: A16-035

Summary

SERVICE BULLETIN – A CREAK IS HEARD FROM THE BASE OF THE B-PILLAR WHEN DRIVING ON UNEVEN SURFACES OR DURING ACCELERATION AND BRAKING. THE SHEET METAL HAS A TOUCH POINT DEEP WITHIN THE BASE OF THE B-PILLAR. TO REMEDY THIS CONDITION, SEPARATE THE SHEET METAL AT THE TOUCH POINT AT THE B-PILLAR ON AFFECTED SIDE ONLY.

A16-035

November 3, 2016

05097 Version 2

03969 Version 1

Creak From the B-pillar

(Supersedes 16-035, Dated July 23, 2016, to revise the information highlighted in yellow)

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2014–15 | Odyssey | ALL | ALL |

| 2016 | Odyssey | ALL | 5FNRL….GB000001 thru 5FNRL….GB044289 |

REVISION SUMMARY

REPAIR PROCEDURE A has been added.

SYMPTOM

A creak is heard from the base of the B-pillar when driving on uneven surfaces or during acceleration and braking.

POSSIBLE CAUSES

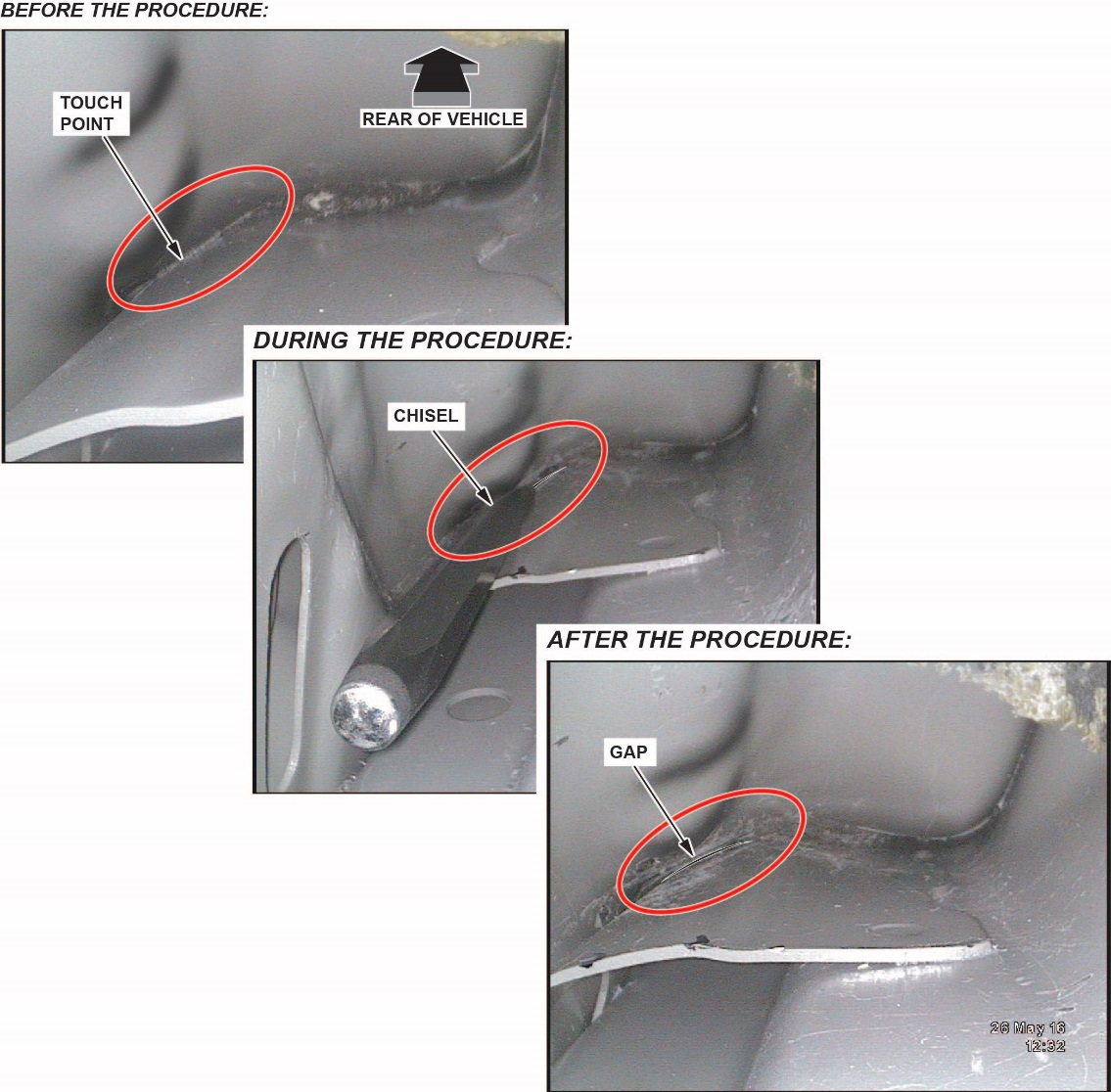

The sheet metal has a touch point deep within the base of the B-pillar.

CORRECTIVE ACTION

Separate the sheet metal at the touch point at the B-pillar on affected side only.

TOOL INFORMATION

| Tool Name | Tool Number | Quantity |

| Snap-on Borescope | BK5600 | 1 |

| Chisel (5.5” X 3/8”) | Snap-on PPC812B or similar | 1 |

| Acid Brush | Commercially Available | 1 |

REQUIRED MATERIALS

| Part Name | Part Number | Quantity |

| Expanding Foam | Commercially Available | 1 |

| Undercoat | Commercially Available | 1 |

DIAGNOSIS

- Test drive the vehicle on an uneven surface (driveway) to determine if the noise is coming from the B-pillar area.

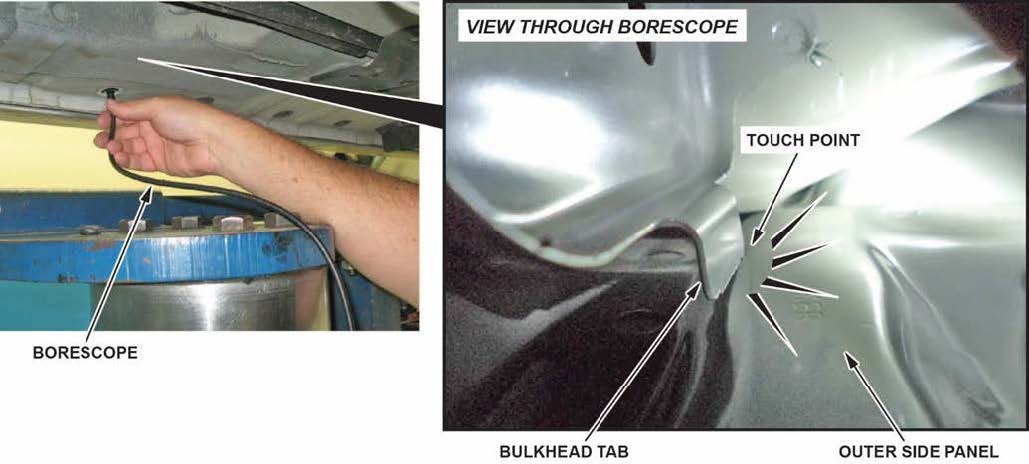

- If the noise is coming from the B-pillar area, raise the vehicle on a lift and, remove the front 20 mm grommet on the side that is making the noise.

- Use a borescope to look straight up into the hole.

- If the bulkhead tab is touching the outer side panel, go to REAPIR PROCEDURE A.

- If the bulkhead tab is not touching the outer side panel, go to REAPAIR PROCEDURE B.

REPAIR PROCEDURE A

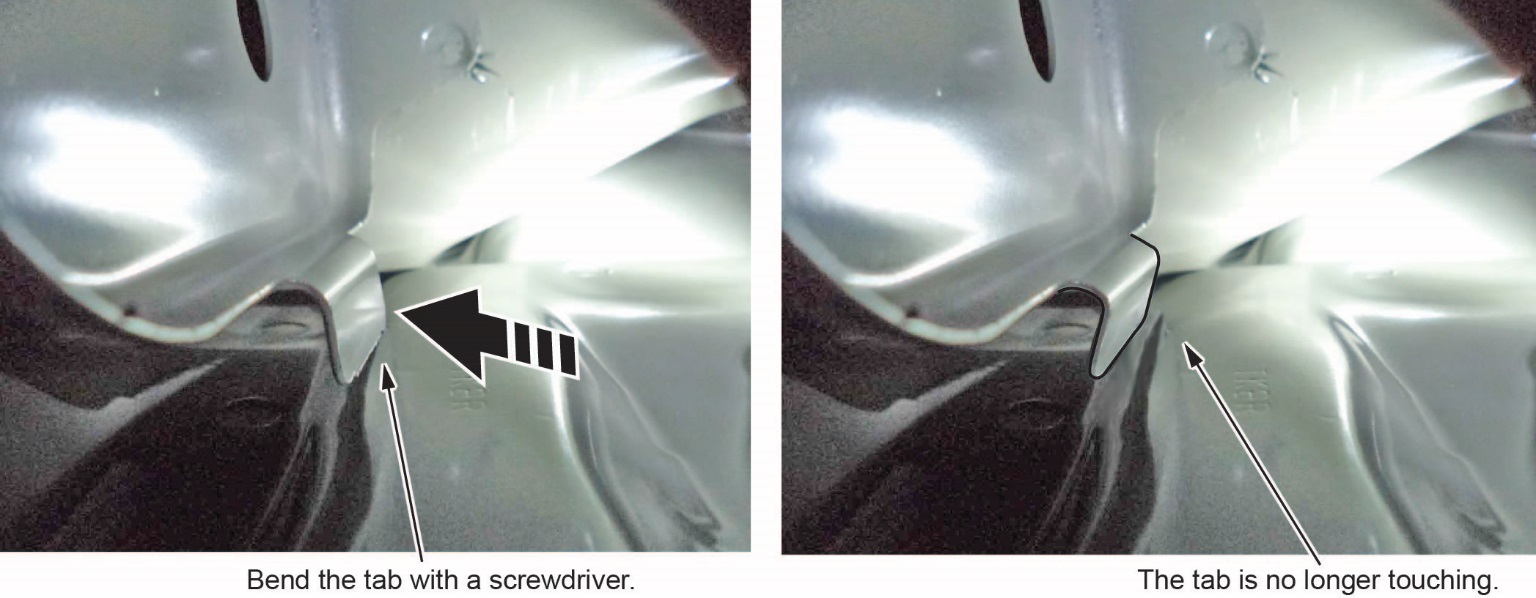

- Use a screwdriver to bend the tab away from the outer side panel.

- After bending the bulkhead tab, test-drive the vehicle to confirm the noise has been eliminated.

- If the noise is gone, no further action is needed.

- If the noise is still present, go to REPAIR PROCEDURE B.

REPAIR PROCEDURE B

NOTE: This procedure is in an outline form. For more information on how to remove these items, refer to the service information.

- Move the seat position and the recliner as far forward as possible.

- Disconnect the battery and wait 3 minutes.

- Remove the middle row seat.

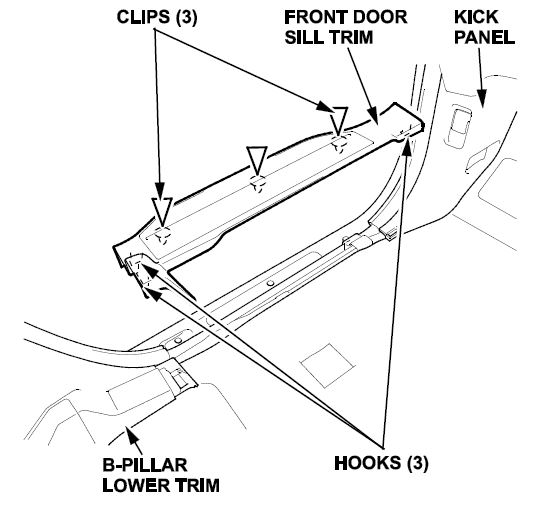

- Remove the front door sill trim.

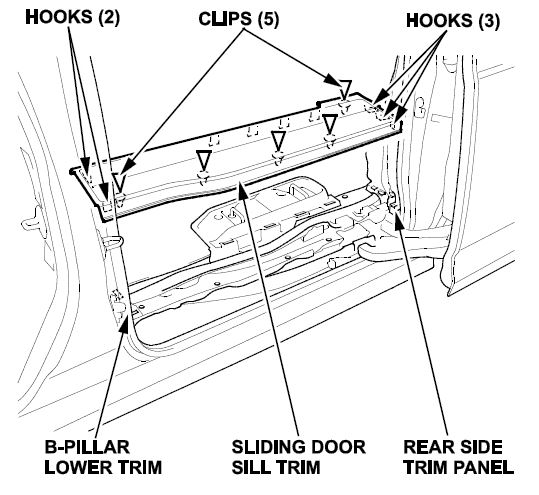

- Remove the sliding door sill trim.

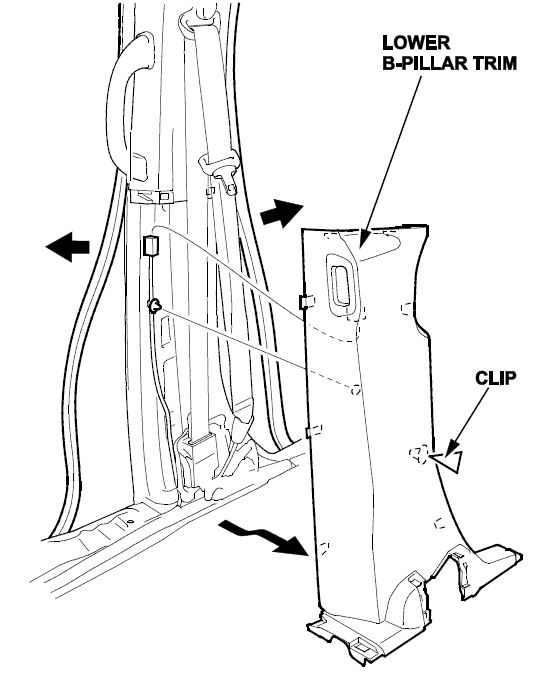

- Remove the lower B-pillar trim.

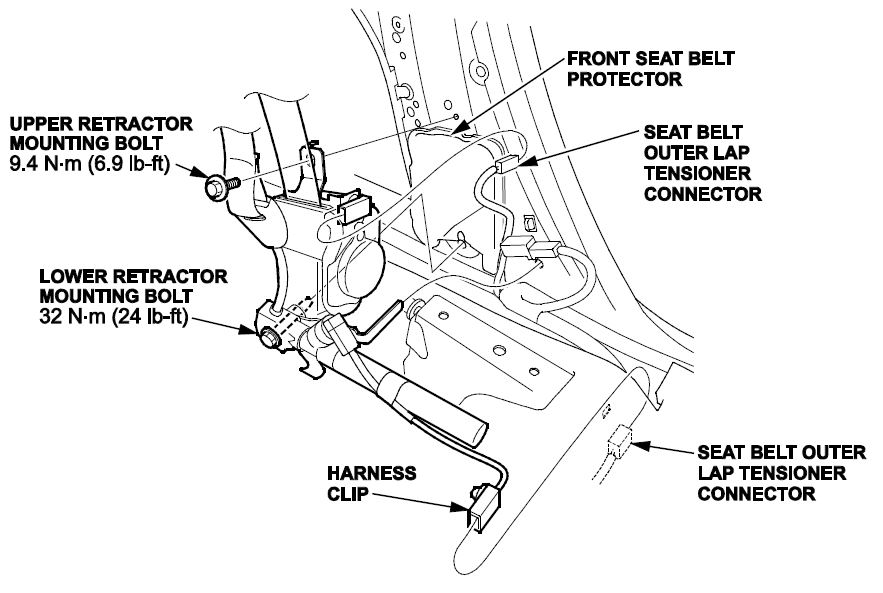

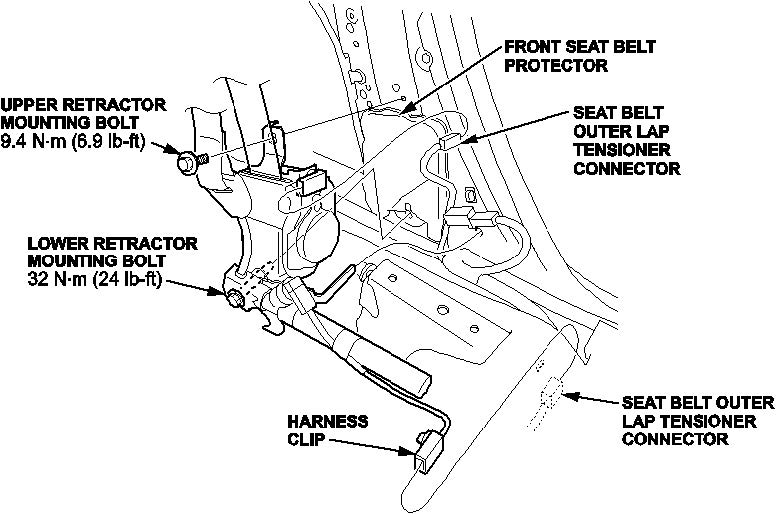

- From under the carpet, disconnect the seat belt tensioner connectors and detach the harness clip. Disconnect the seat belt outer lap tensioner connector, then place the retractor on the front seat.

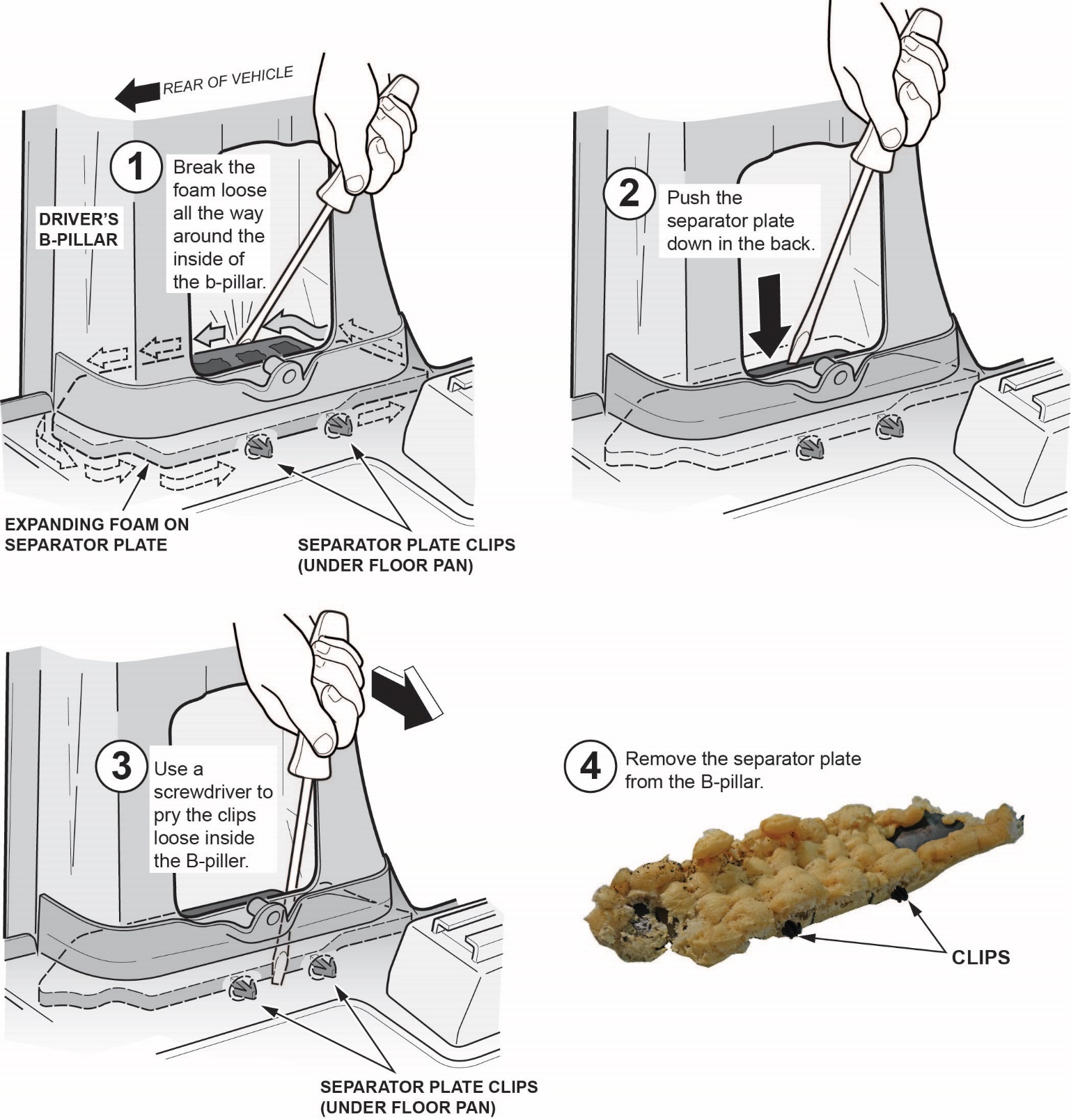

- Use a large flat-blade screwdriver or pry bar to separate the expanding foam that is applied to the plastic separator plate from the inner walls of the B-pillar as shown. Push the back edge of the separator plate down into the B-pillar, then remove the separator plate.

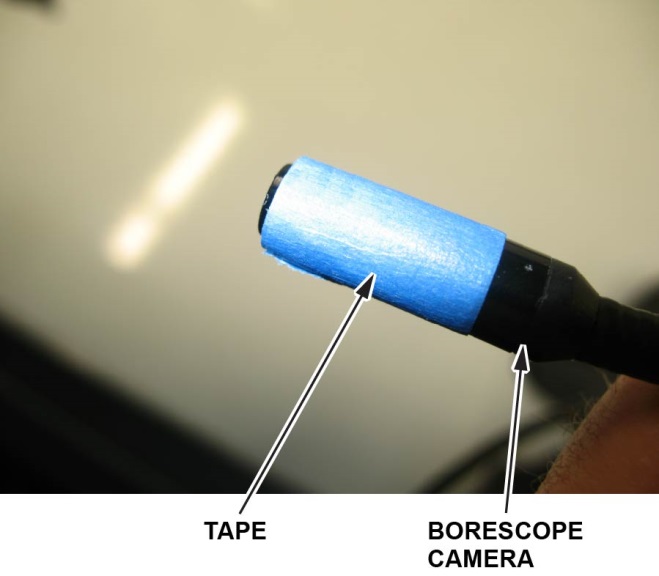

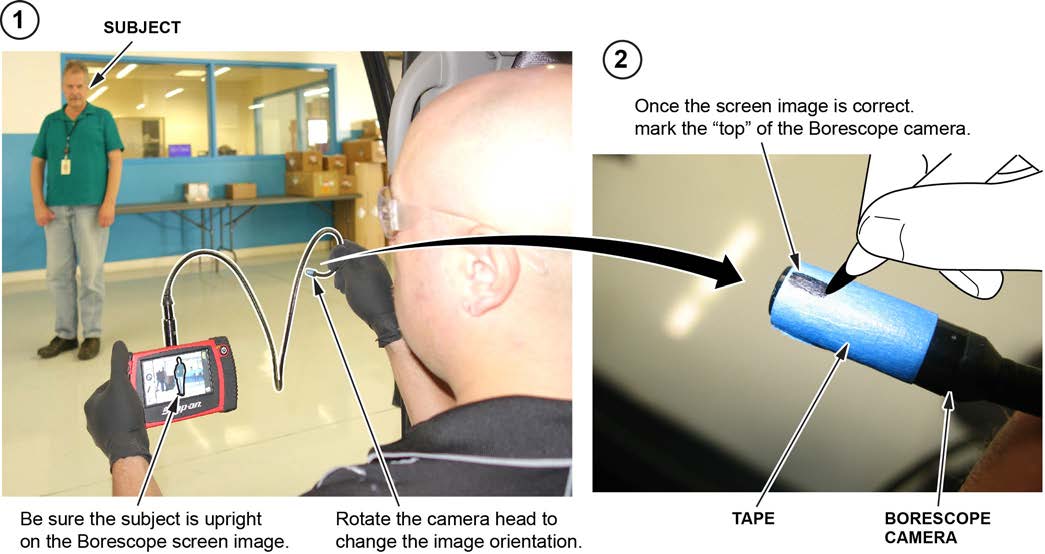

- Wrap some masking tape around the front edge of the borescope camera.

- Turn on the borescope and adjust the camera until you get the display level as shown. Then, put a mark on top of the tape to show the correct orientation for the display.

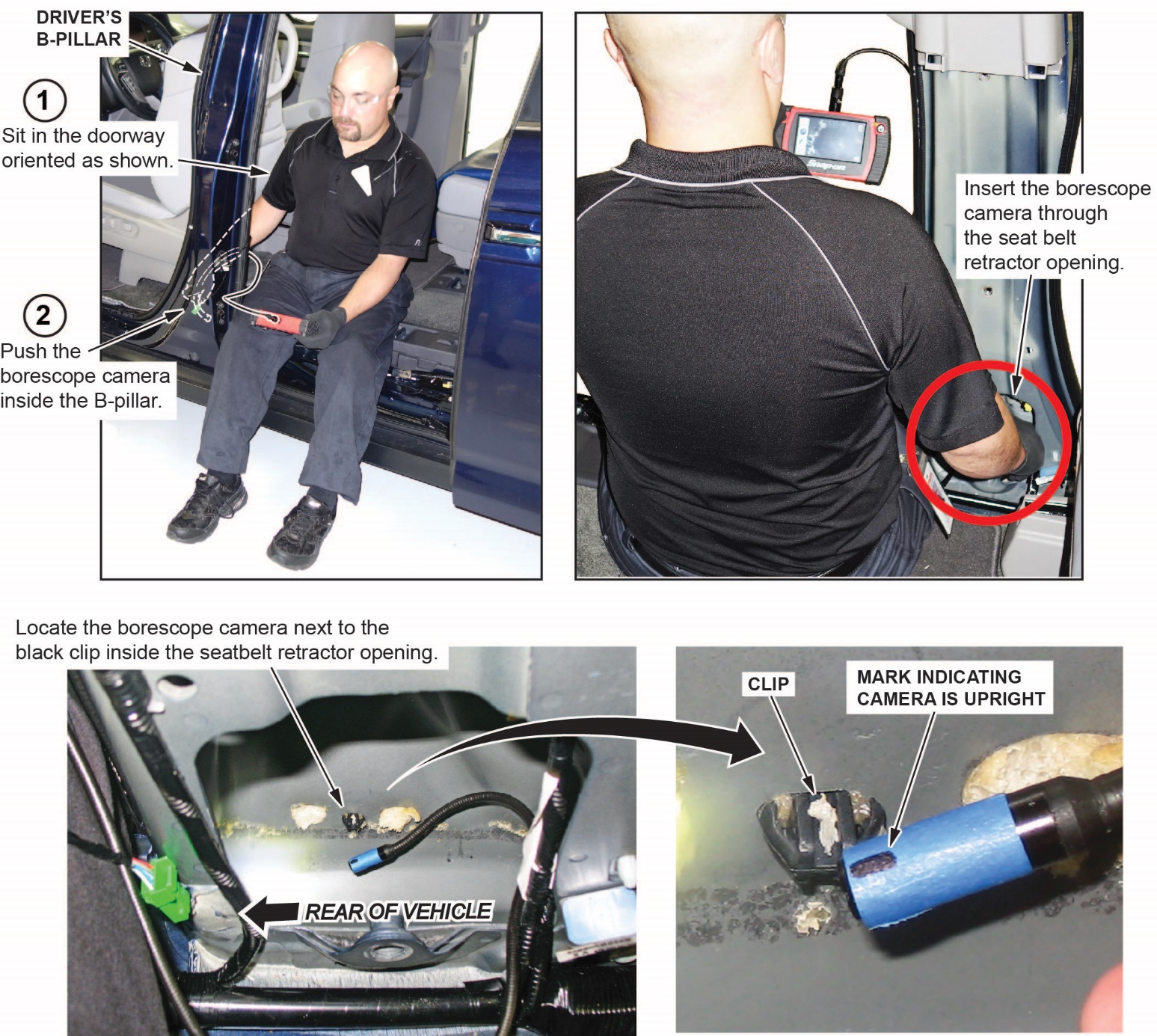

- From a sitting position in the door opening, insert the borescope camera down into the seat belt retractor opening. Place the camera near the black plastic clip and aim toward the rear of the vehicle as shown.

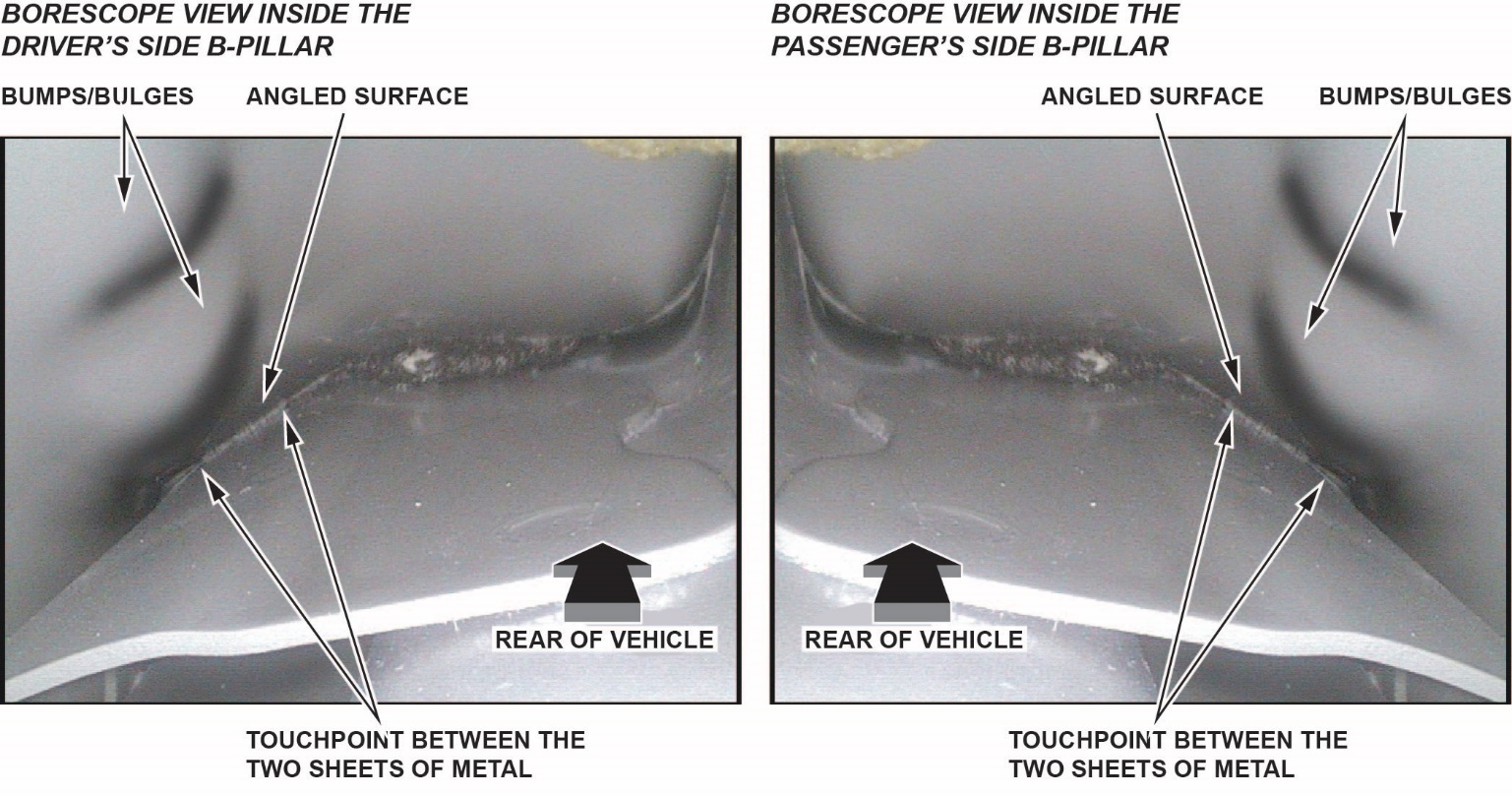

- Position the camera to inspect the specified location to confirm the touch point area.

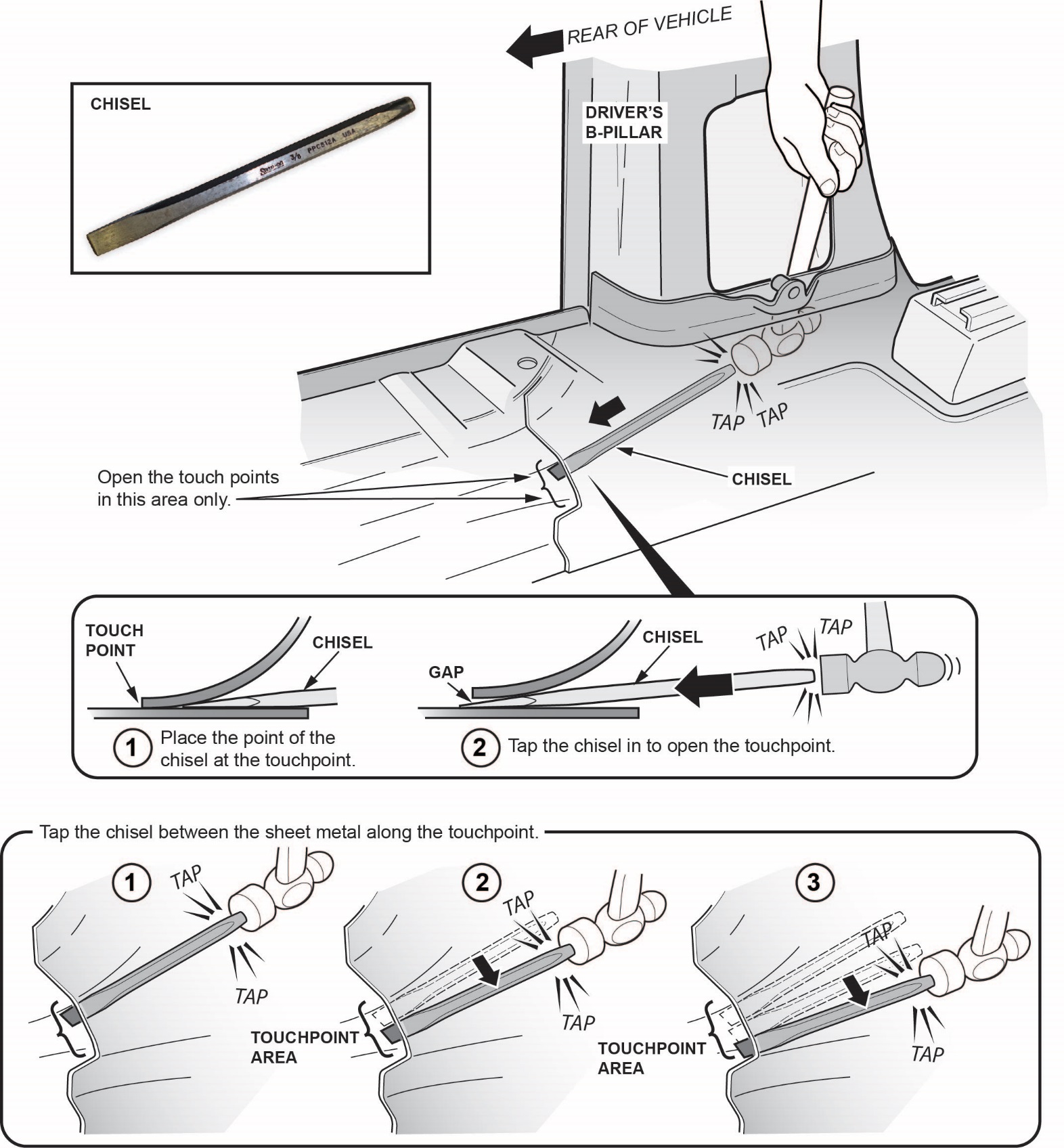

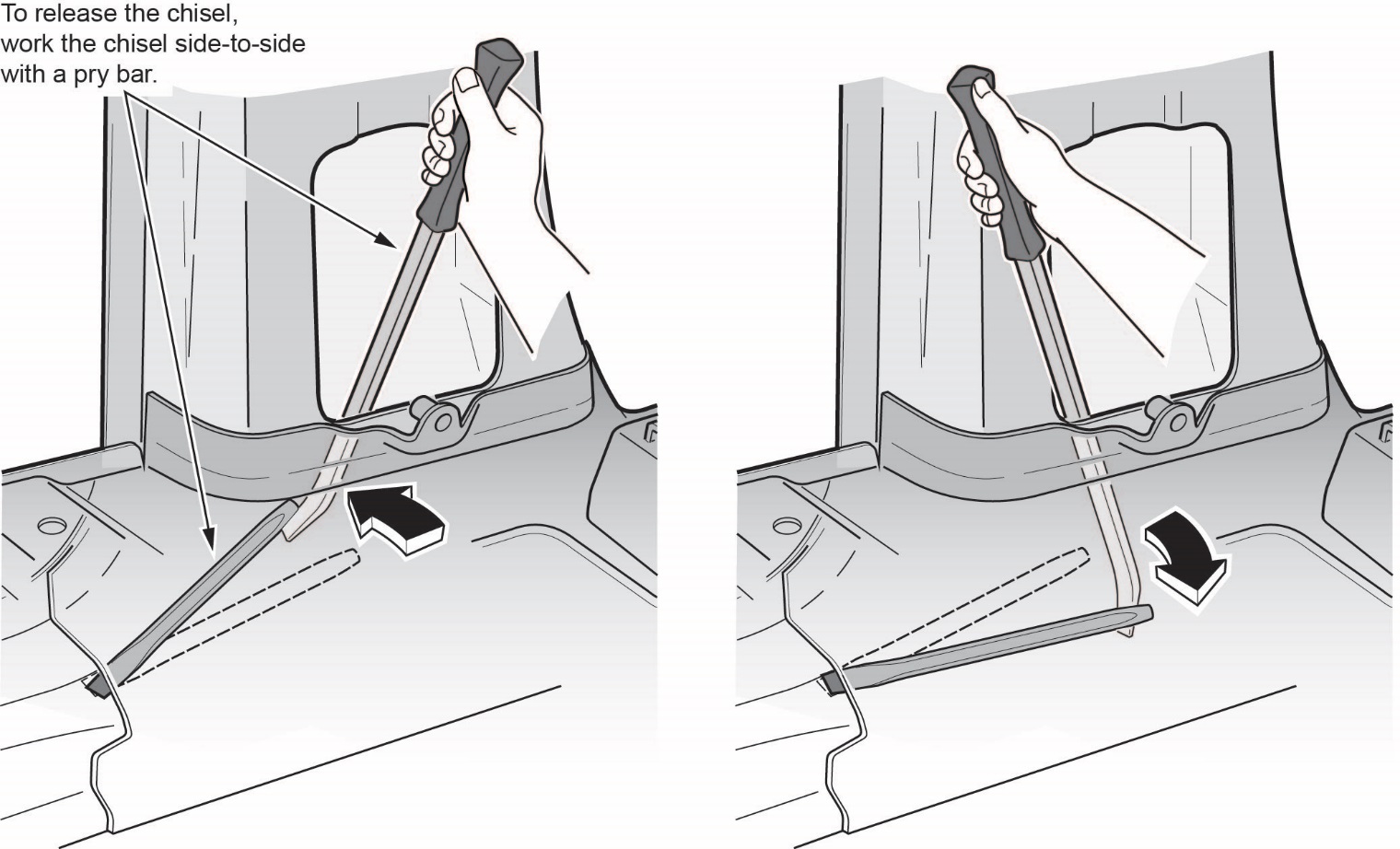

- Using a hammer and a small chisel, separate the sheet metal all along the touch points. Tap the chisel several times to obtain separation. NOTE:

- Drive the chisel in between the sheet metal in several locations to get the proper separation along the touch point area.

- You will need to use a pry bar to remove the chisel from the B-pillar. Work it side to side to remove it.

- DO NOT pry up or down on the chisel; it could break off in the B-pillar.

- After separating the sheet metal, temporarily install the seatbelt retractor and reconnect the battery.

- Test-drive the vehicle to confirm the noise has been eliminated.

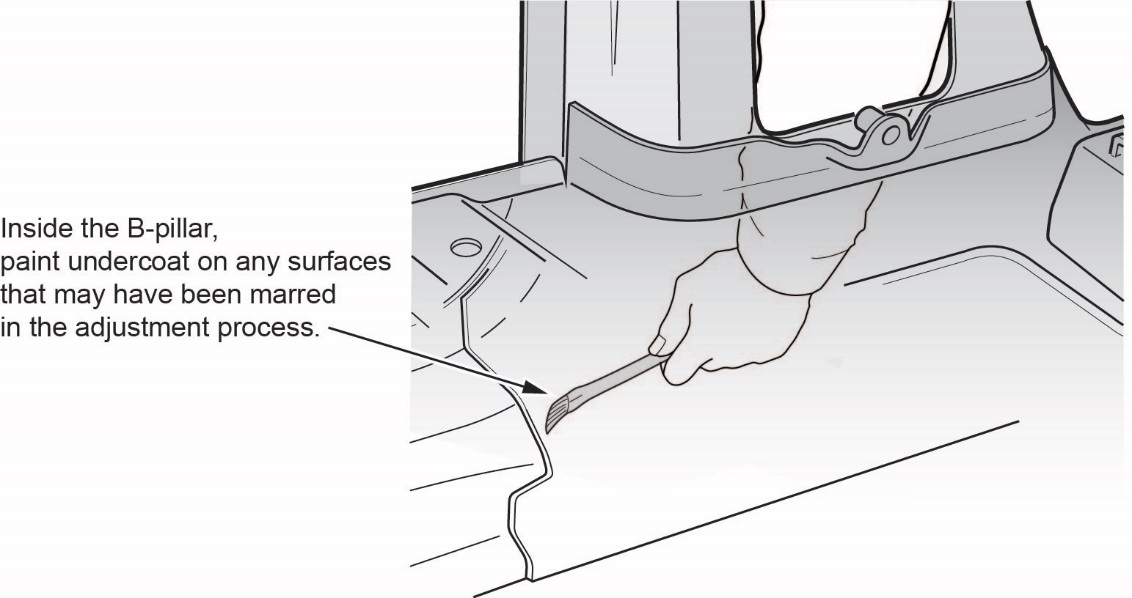

- Apply undercoat to the separation area to prevent rust.

- Install the plastic separator plate.

NOTE: The clips on the plastic separator may have been deformed during removal. Bend or trim the clips as needed to help inserting them back into the holes.

- Seal the plastic separator by applying commercially available expanding foam around the perimeter.

- Install all removed parts and torque the retractor upper mounting bolts to 4 N·m (6.9 lb-ft) and the lower retractor mounting bolts to 32 N·m (24 lb-ft).

- Repeat on the opposite side if necessary.

END

3 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

HONDA | ODYSSEY | 2014-2016 |

1 Associated Document

Service Bulletin Document

A16-035

July 23, 2016

03969 Version 1

SB-10084521-2280.pdf 1929.683KB

Loading...

Loading...

- Expands To Fill: Loctite Tite Foam Gaps & Cracks fills, seals, and insulates effectively around gaps and cracks up to 1 inch in size

- Premium Durability: Polymer foam based on purified and concentrated ingredients withstands harsh UV rays for long-lasting results

- High Density Foam: Offers high density with a uniform cell structure for durability and overall insulation for your remodeling needs

- Superior Flexibility: Withstands building and material movement without compromising its seal

- Strong Adhesion: Sealant bonds to most building materials like wood, concrete, brick, stone, metal, pvc, and more

- Expands To Fill: Loctite Tite Foam Big Gaps fills, seals, and insulates effectively around gaps and cracks up to 3 inches in size

- High Density Foam: Offers high density with a uniform cell structure for durability and overall insulation for your remodeling needs

- Superior Flexibility: Withstands building and material movement without compromising its seal

- Strong Adhesion: Sealant bonds to most building materials like wood, concrete, brick, stone, metal, pvc, and more

- UV Resistance: Withstands harsh UV rays for long lasting results

- THE GAP AND CRACK ATTACKER! Reduce drafts and save energy

- THE GAP AND CRACK ATTACKER! Reduce drafts and save energy

- No drips, less mess - foam stops where you stop

- Reusable for up to 30 days - use again and again

- Precise, greater control

- Forms a permanent weather-tight seal to minimize drafts and insect infestation

- Exceptional adhesion to building materials

- Interior or exterior use

- Tack free in 6 minutes; Trims in 30 minutes

- Foam elasticity allows for movement/shifting within a structure

- FILLS LARGE HOLES, GAPS & CRACKS: Ideal for insulating and preventing drafts

- USE INSIDE OR OUTSIDE: Can be used anywhere around the home

- SANDABLE, PAINTABLE & STAINABLE: Can be sanded, painted or stained after curing

- ADHERES TO: Painted and unpainted wood, concrete, cinder block, aluminum & fiberglass

- SOLVENT CLEAN UP: Requires the use of a solvent for cleanup

- Multi-purpose formula: This polyurethane sealant is an ideal foam insulation and gap filler of up to 1 inch voids or cracks

- Fast dry: Gorilla insulation foam dries fast and is trimmable in 45 minutes, sealing out air, moisture, pests, and insects quickly

- No warping/bowing formula: Our spray insulation meets AAMA 812-19, meaning no warping or bowing

- No shrinkage: When cured, our spray foam insulation maintains its integrity even in extreme temperature swings

- Use on: Our polyurethane foam is ideal for wood, metal, glass, masonry, plumbing, HVAC, electrical**, basements, crawlspaces, attics, ceilings, skylights, and more.

- Tomcat Rodent Block Expanding Foam Barrier fills gaps and cracks to block mice from coming inside your home

- Our spray foam is the pesticide-free way to create a rodent barrier

- This expanding foam provides a long-lasting, airtight, and water-resistant bond to most building materials

- Spray in crevices inside and outside your house, including the garage, attic, basement, and foundation

- Tomcat Rodent Block Expanding Foam Barrier can be trimmed, sanded, and painted if desired

- EASY TO DISPENSE: Kraken Bond Spray Foam Insulation features a single-component, moisture-curing, and self-expanding aerosol polyurethane foam. Designed for easy dispensing through the straw adapter included with each can.

- SAFETY & QUALITY ASSURED – Kraken Bond expanding foam sealant is UL 723 certified, meeting strict safety and performance standards for ultimate reliability.

- OPTIMAL TEMPERATURE GUIDANCE FOR BEST RESULTS: Achieve peak performance by ensuring the can is at an optimal temperature of 68°F before use. Application is effective in a range of 41°F to 86°F, allowing for flexibility in varying weather conditions. For cold climates, let the can acclimate to room temperature to maintain top-notch results without any compromise in product quality or performance.

- VERSATILE USE: Perfect for filling window and door frames, large gaps, joints, cavities, electrical outlets, water pipes, and wall penetrations. A dependable solution for multiple applications.

- SAFE AND EFFECTIVE: Recommended for use with Kraken Bond Spray Foam Cleaner (sold separately). Ensure safety by wearing protective gloves, safety glasses, and protective clothing during application.

- FILL BIGGER GAPS. This expanding foam insulation fills, seals and insulates gaps up to 3". This ready-to-use sealant is specially formulated to take on common areas of energy loss such as rim joists/sill plates, plumbing, HVAC and larger penetrations.

- STRAW-APPLIED. Save time on your projects with this simple to use spray foam — the straw applicator makes any project a breeze and helps you deliver the right amount of insulating foam even in hard to reach spaces.

- SPRAY ANYWHERE. Tackle a variety of projects with exceptional adhesion to building materials on both the interior and exterior of your home. Adheres to wood, metal, masonry, glass and most plastics.

- QUICK-CURE. Stop waiting around and keep the pace of your projects on target. This foam sealant dries tack-free in 20 minutes and cures rigid for trimming in 1 hour. Trim, sand, stain and paint for a truly GREAT finish to your projects.

- FILL MORE GAPS. Get the job done right the first time with this cost-effective bulk case of polyurethane foam crack filler from GREAT STUFF. Includes an 8-count of 12 oz. cans, each with dispensing straws to cover all your gaps and cracks.

- Use foam insulation sprayer to fill, air seal, and insulate stud wall cavities, rim joists, crawlspaces, attics and basements on homes and buildings

- Closed cell spray foam formula keeps moisture out of structures and is Class A Fire Rated to meet building codes; interior use on a variety of materials: including wood, masonry, metals, drywall

- Foam dries tack free in 7 to 12 minutes and fully cures in 4 hours (depending on foam thickness, temperature/humidity)

- Patent pending technology provides spray similar to a two-component product in an easy one part system; Wide spray applicator with responsive flow control trigger and a consistent wide-angle pattern

- Enhances R-Value of structures, seals out air and provides thermal insulation savings year round; saves energy and up to 30% on energy costs - meets ASTM C518 Aged R-Value of 4.1 at 1" (25mm)

SEOCONTENT-START

CUSTOMER INFORMATION: The information in this bulletin is intended for use only by skilled technicians who have the proper tools, equipment, and training to correctly and safely maintain your vehicle. These procedures should not be attempted by “do-it-yourselfers,” and you should not assume this bulletin applies to your vehicle, or that your vehicle has the condition described. To determine whether this information applies, contact an authorized Honda automobile dealer. © 2016 American Honda Motor Co., Inc. – All Rights Reserved Page 1 of 13

Service Bulletin 16-035

July 23, 2016 03969 Version 1 Creak From the B-pillar AFFECTED VEHICLES

Year Model Trim VIN Range

2014–15 Odyssey ALL ALL

2016 Odyssey ALL 5FNRL….GB000001 thru 5FNRL….GB044289 SYMPTOM

A creak is heard from the base of the B-pillar when driving on uneven surfaces or during acceleration and braking.

POSSIBLE CAUSES

The sheet metal has a touch point deep within the base of the B-pillar. CORRECTIVE ACTION

Separate the sheet metal at the touch point at the B-pillar on affected side only. TOOL INFORMATION

Tool Name Tool Number Quantity

Snap-on Borescope BK5600 1

Chisel (5.5” X 3/8”) Snap-on PPC812B or similar 1

Acid Brush Commercially Available 1 REQUIRED MATERIALS

Part Name Part Number Quantity

Expanding Foam Commercially Available 1

Undercoat Commercially Available 1 WARRANTY CLAIM INFORMATION

The normal warranty applies. Operation Number

8570A8 Description

Separate the sheet metal at the touch point at the B-pillar on affected side only (left or right side). Flat Rate Time

1.9 hrs Defect Code

07406 Symptom Code

04201 Template ID

16-035A Failed Part Number

63610-TK8-306ZZ 8570A8

A Separate the sheet metal at the touch point at the B-pillar on affected side only (left or right side).

For additional side (if necessary) – add 1.9 hrs

1.9 hrs 07406 04201 16-035B 63610-TK8-306ZZ Skill Level: Repair Technician DIAGNOSIS

1. Test drive the vehicle on an uneven surface (driveway) to determine if the noise is coming from the B-pillar area.

• If the noise is coming from the B-pillar. Go to REPAIR PROCEDURE.

• If the noise is not coming from the B-pillar, continue with normal troubleshooting. REPAIR PROCEDURE

NOTE: This procedure is in an outline form. For more information on how to remove these items, refer to the service information.

1. Move the seat position and the recliner as far forward as possible.

2. Disconnect the battery and wait 3 minutes.

3. Remove the middle row seat.

4. Remove the front door sill trim. Page 2 of 13 5. Remove the sliding door sill trim.

HOOKS (2) CLIPS (3) \

l c:: J B-PILLAR LOWER TRIM SLIDING DOOR REAR SIDE SILL TRIM TRIM PANEL 6. Remove the lower B-pillar trim. LOWER

B-PILLAR TRIM p Page 3 of 13 7. From under the carpet, disconnect the seat belt tensioner connectors and detach the harness clip. Disconnect the seat belt outer lap tensioner connector, then place the retractor on the front seat. Page 4 of 13 8. Use a large flat-blade screwdriver or pry bar to separate the expanding foam that is applied to the plastic separator plate from the inner walls of the B-pillar as shown. Push the back edge of the separator plate down into the B-pillar, then remove the separator plate. Page 5 of 13 9. Wrap some masking tape around the front edge of the borescope camera. 10. Turn on the borescope and adjust the camera until you get the display level as shown. Then, put a mark on top of the tape to show the correct orientation for the display. Page 6 of 13 11. From a sitting position in the door opening, insert the borescope camera down into the seat belt retractor opening. Place the camera near the black plastic clip and aim toward the rear of the vehicle as shown. Page 7 of 13 12. Position the camera to inspect the specified location to confirm the touch point area. Page 8 of 13 13. Using a hammer and a small chisel, separate the sheet metal all along the touch points. Tap the chisel several times to obtain separation.

NOTE:

• Drive the chisel in between the sheet metal in several locations to get the proper separation along the touch point area.

• You will need to use a pry bar to remove the chisel from the B-pillar. Work it side to side to remove it.

• DO NOT pry up or down on the chisel; it could break off in the B-pillar. . Page 9 of 13 Page 10 of 13 Page 11 of 13 14. After separating the sheet metal, temporarily install the seatbelt retractor and reconnect the battery.

15. Test-drive the vehicle to confirm the noise has been eliminated.

16. Apply undercoat to the separation area to prevent rust. 17. Install the plastic separator plate.

NOTE: The clips on the plastic separator may have been deformed during removal. Bend or trim the clips as needed to help inserting them back into the holes.

18. Seal the plastic separator by applying commercially available expanding foam around the perimeter. Page 12 of 13 Page 13 of 13

19. Install all removed parts and torque the retractor upper mounting bolts to 9.4 N·m (6.9 lb-ft) and the lower retractor mounting bolts to 32 N·m (24 lb-ft).

20. Repeat on the opposite side if necessary.

END

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.