| “This site contains affiliate links for which OEMDTC may be compensated” |

B16-008

October 4, 2016

04983 Version 3

High Pressure Fuel Pump Chirps

(Supersedes 16-008, dated April 30, 2016, to revise the information highlighted in yellow)

AFFECTED VEHICLES

| Year | Model | Trim | VIN range |

| 2014–17 | MDX | ALL | ALL |

| 2015–17 | TLX | ALL with V6 | ALL |

| 2014–17 | RLX | ALL | ALL |

| 2014 and 2016 | RLX Hybrid | ALL | ALL |

REVISION SUMMARY

Under AFFECTED VEHICLES, the model year 2017 was added to the MDX, TLX, and RLX.

SYMPTOM

The high pressure fuel pump area chirps after the engine is warm.

POSSIBLE CAUSES

The high pressure fuel pump is making a chirp.

NOTE: This noise does not impact pump, engine function, or reliability.

CORRECTIVE ACTION

Replace the high pressure fuel pump.

PARTS INFORMATION

| Part Name | Part Number | Quantity |

| Fuel Joint Pipe Set | 16012-R9P-305 | 1 |

| High Pressure Fuel Pump | 16790-5J6-305 | 1 |

| Retainer | 17711-S0X-931 | 1 |

| Intake Manifold Gasket (top) | 17112-5G0-A01 | 1 |

| Intake Manifold Gasket | 17105-R9P-A01 | 1 |

| Intake Manifold Base Gasket (RR) | 17065-R9P-A01 | 1 |

| Intake Manifold Base Gasket (FR) | 17055-R9P-A01 | 1 |

WARRANTY CLAIM INFORMATION

The normal warranty applies.

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 1211U6 | Replace the high pressure fuel pump (MDX). | 1.8 hrs | 03214 | 04201 | 16-008N | 16790-5J6-305 |

| 1211FG | Replace the high pressure fuel pump (TLX). | 1.9 hrs | 03214 | 04201 | 16-008P | 16790-5J6-305 |

| 1211U6 | Replace the high pressure fuel pump (RLX). | 1.7 hrs | 03214 | 04201 | 16-008Q | 16790-5J6-305 |

| 1211U6 | Replace the high pressure fuel pump (RLX Hybrid). | 1.7 hrs | 03214 | 04201 | 16-008R | 16790-5J6-305 |

Skill Level: Repair Technician

DIAGNOSIS

- If the noise is coming from the high pressure fuel pump, go to REPAIR PROCEDURE.

- If the noise is coming from the timing belt area, refer to service bulletin 14-025, Timing Belt Chirps.

- If the noise is not coming from the high pressure fuel pump or timing belt, continue with normal troubleshooting.

REPAIR PROCEDURE

- Relieve the fuel pressure.

- Set the No. 1 piston at top dead center (TDC).

- Remove the intake manifold and intake manifold base. See service information.

Note: Removal of the throttle body from the intake manifold is not required. Seal the two water hoses and leave it attached to the intake manifold

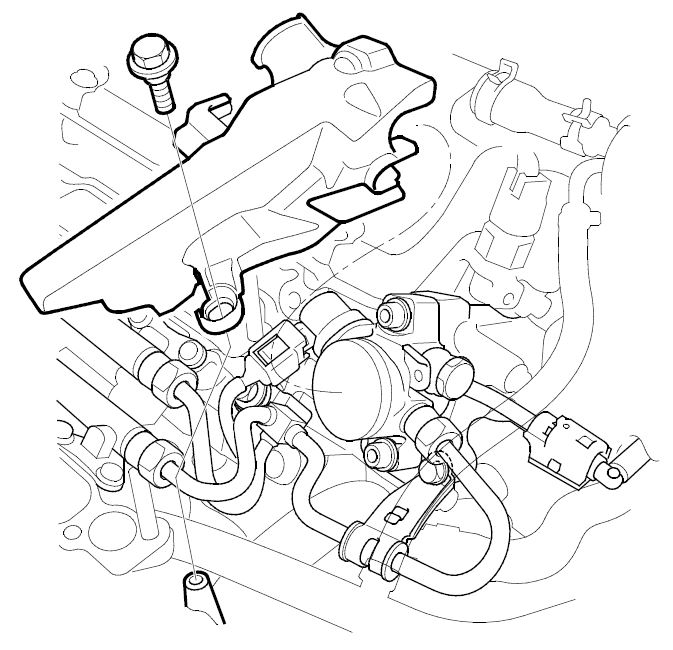

- Remove the high pressure fuel pump cover.

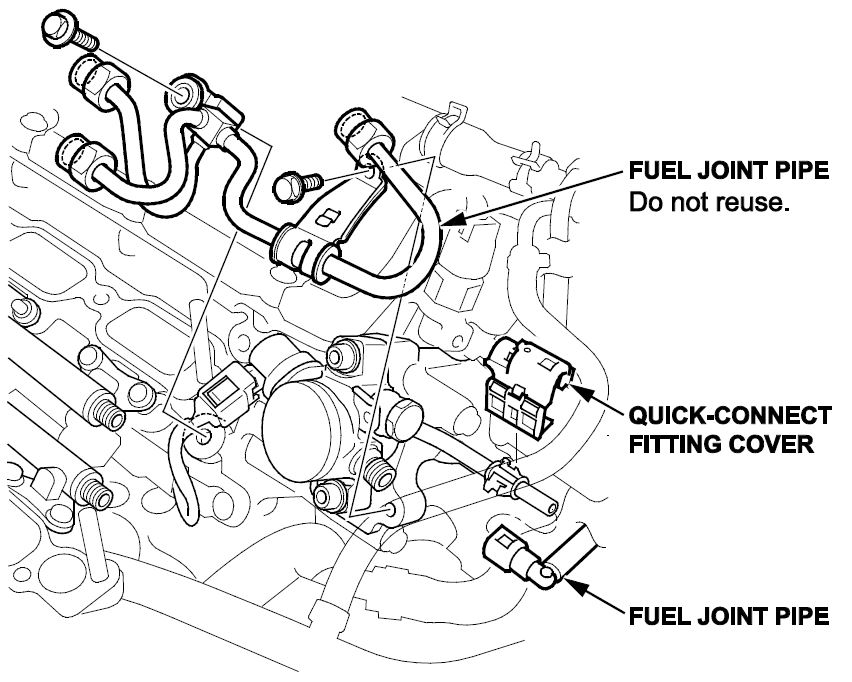

- Remove the quick-connect fitting cover.

- Disconnect the quick-connect fitting.

- Remove the fuel joint pipe.

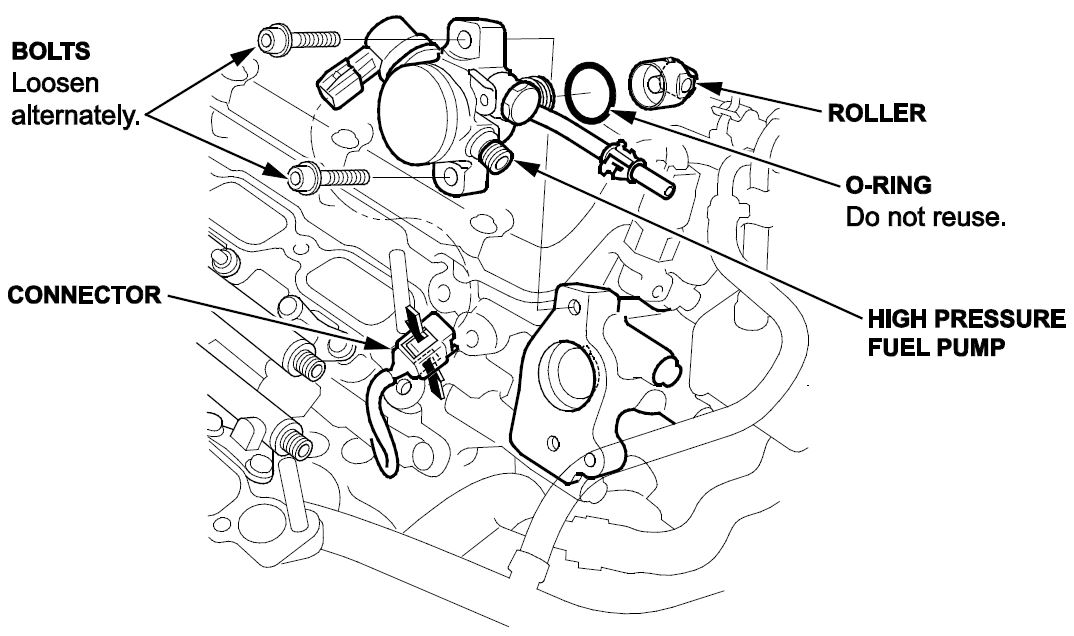

- Disconnect the high pressure fuel pump connector.

- Remove the bolts by loosening them alternately, then remove the high pressure fuel pump and the roller.

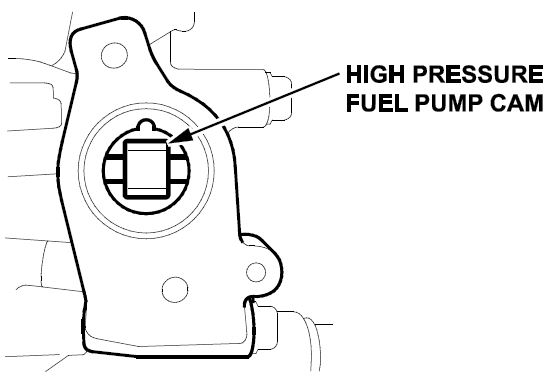

- Rotate the crankshaft and check the high pressure fuel pump cam for pits, scores, and excessive wear. If needed, replace the rear camshaft.

- Set the No. 1 piston at top dead center (TDC).

- Install the roller onto the high pressure fuel pump cam.

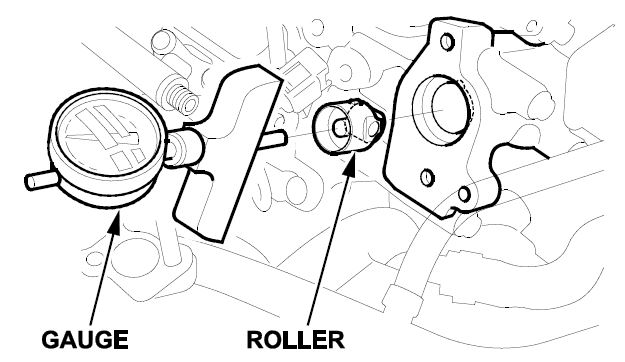

- Set the gauge on the roller and hold it, then set the dial to zero.

- Rotate the crankshaft 720° and measure the three cam lobes height. If the cam lobes are excessively worn, replace the rear camshaft.

NOTE: The high pressure fuel pump cam has three cam lobes. Cam Lobe Height Standard (New): 0.236 in (6.0 mm)

- Set the No. 1 piston at top dead center (TDC).

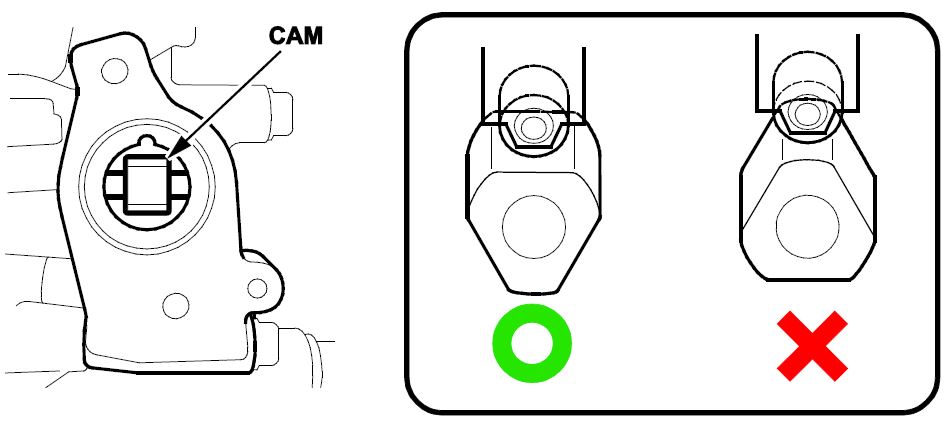

- Check the position of the cam that drives the high pressure fuel pump as shown.

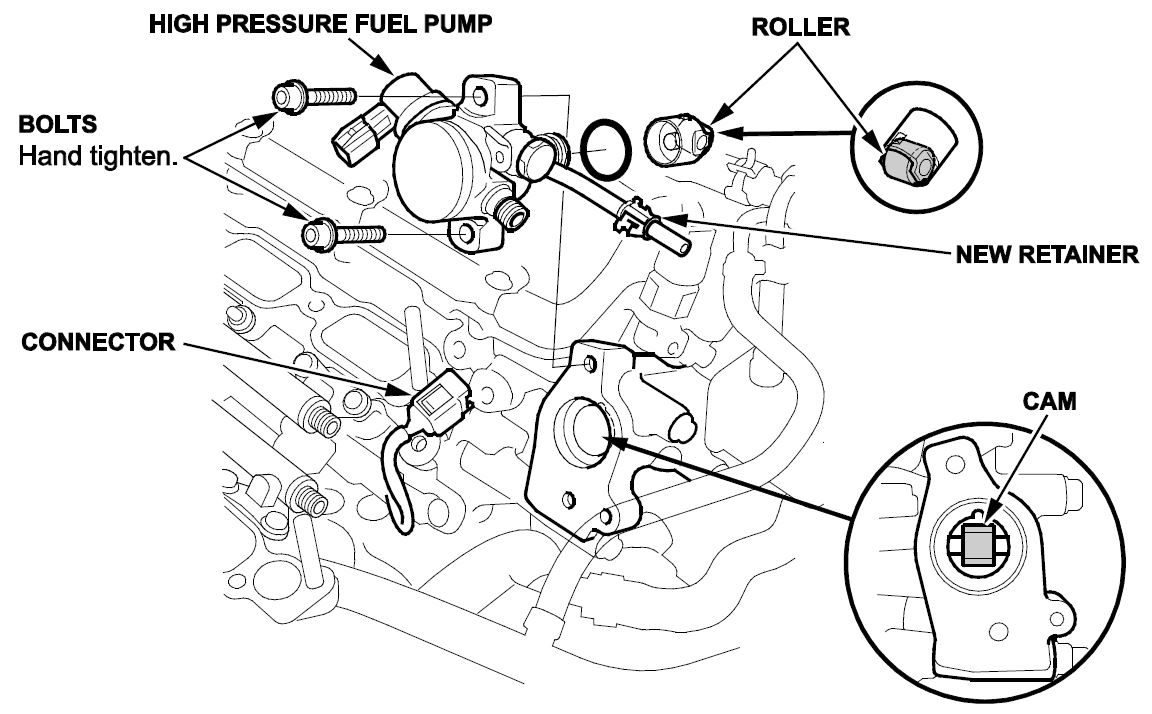

- Coat the roller and the cam with clean engine oil.

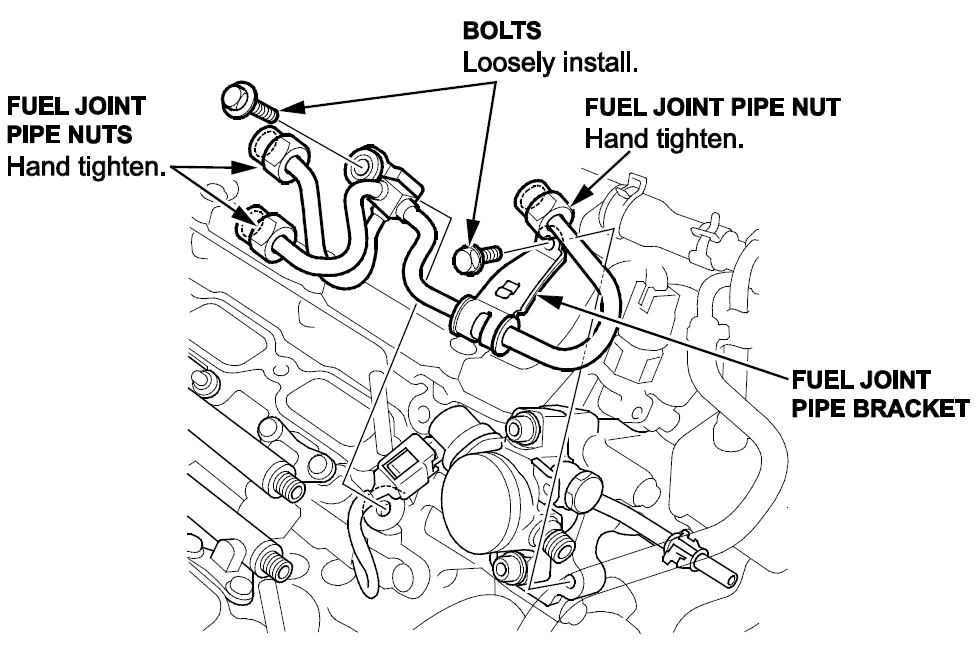

- Install the roller and the high pressure fuel pump. Install the bolts loosely by hand in an alternate pattern. Connect the connector.

NOTE: Failure to install a new fuel joint pipe will cause fuel leaks.

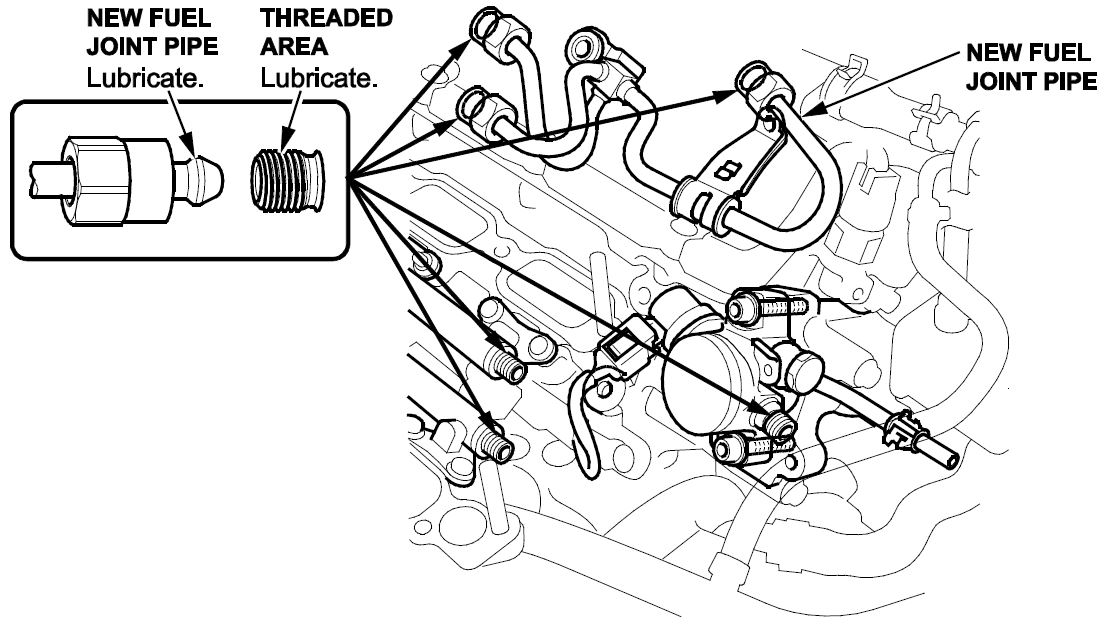

- Lubricate the top of the new fuel joint pipe and the threaded area of the fuel rails and the high pressure fuel pump with polyethylene glycol included in the new fuel joint pipe kit. NOTE: Do not reuse the fuel joint pipe.

- Tighten the fuel joint pipe nuts by hand until the end of the joint pipe is seated on the fuel rails and high pressure fuel pump.

- Set the fuel joint pipe bracket on the cylinder head and loosely install the bolts

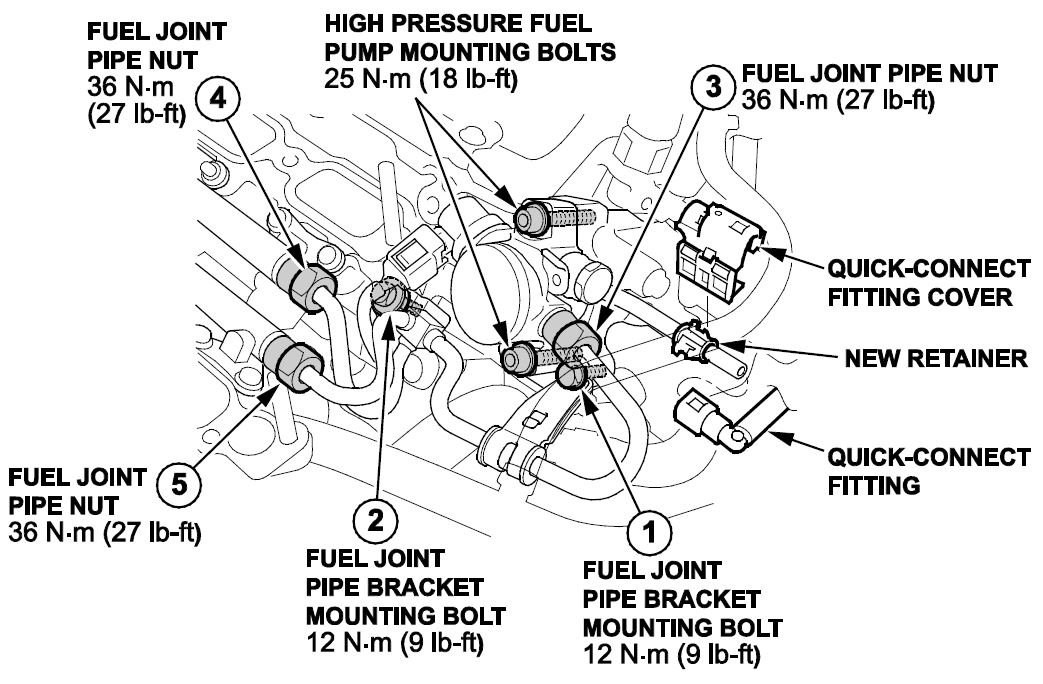

- Tighten the high pressure fuel pump mounting bolts to the specified torque.

- Tighten the fuel joint pipe bracket mounting bolts and the fuel joint pipe nuts to the specified torque in the numbered sequence shown.

NOTE:

- A crowfoot-type special tool increases the torque applied by the torque wrench. Refer to Torque Specifications for details on how to recalculate the torque wrench setting.

- Failure to tighten the fuel joint pipe nuts to the proper torque will cause a fuel leak.

- Connect the quick-connect fitting and install the quick-connect fitting cover.

- Set the power mode to ON, but do not start the engine. After the fuel pump runs for about 2 seconds, the fuel line will be pressurized. Repeat this two or three times, then check for fuel leakage.

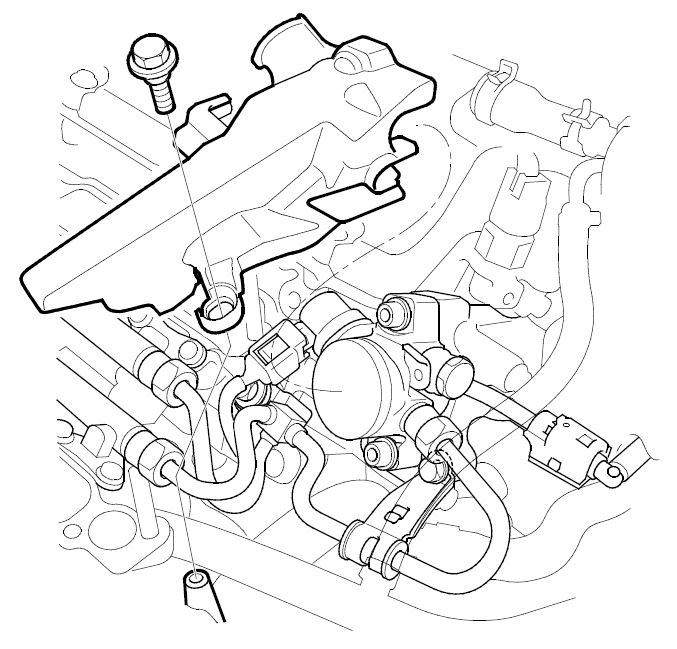

- Install the high pressure fuel pump cover and torque it to 12 N·m (9 lb-ft).

- Install the intake base and intake manifold.

END

Loading...

Loading...