| “This site contains affiliate links for which OEMDTC may be compensated” |

April 12, 2019

Timing Belt Teeth May Separate

Teeth separation from the timing belt may result in an engine stall, increasing the risk of crash.

NHTSA Campaign Number: 19V298

Manufacturer Honda (American Honda

(American Honda Motor Co.)

Motor Co.)

Components ENGINE AND ENGINE COOLING

Potential Number of Units Affected 93,946

Summary

Honda (American Honda

(American Honda Motor Co.) is recalling certain 2018-2019 Acura

Motor Co.) is recalling certain 2018-2019 Acura MDX and Honda

MDX and Honda Pilot vehicles and 2019 Acura

Pilot vehicles and 2019 Acura RLX, RLX Sport Hybrid, TLX and Honda

RLX, RLX Sport Hybrid, TLX and Honda Odyssey and Ridgeline vehicles. The timing belt teeth may separate from the belt.

Odyssey and Ridgeline vehicles. The timing belt teeth may separate from the belt.

Remedy

Honda will notify owners, and dealers will inspect the vehicle and replace any affected timing belt free of charge. Vehicles receiving a replacement timing belt will also have the engine inspected and any damaged components will be replaced for free. The recall is expected to begin June 1, 2019. Honda

will notify owners, and dealers will inspect the vehicle and replace any affected timing belt free of charge. Vehicles receiving a replacement timing belt will also have the engine inspected and any damaged components will be replaced for free. The recall is expected to begin June 1, 2019. Honda owners may contact customer service at 1-888-234-2138. Honda

owners may contact customer service at 1-888-234-2138. Honda ’s number for this recall is L4M. Acura

’s number for this recall is L4M. Acura owners may contact customer service at 1-888-234-2138. Acura

owners may contact customer service at 1-888-234-2138. Acura ’s number for this recall is Z4L.

’s number for this recall is Z4L.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Honda has a Recall

Service Bulletin

A19-045

April 12, 2019

Version 2

Safety Recall: 3.5L V6 Timing Belt

Supersedes 19-045, dated April 12, 2019, to revise the information highlighted in yellow

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2019 | Odyssey | ALL | Check the iN VIN status for eligibility. |

| 2018-19 | Pilot | ALL | Check the iN VIN status for eligibility. |

| 2019 | Ridgeline | ALL | Check the iN VIN status for eligibility. |

REVISION SUMMARY

- Under REQUIRED MATERIALS, the Honda

Genuine Motor Oil part number was updated.

Genuine Motor Oil part number was updated. - Under INSPECTION, Step 5 was changed.

BACKGROUND

During production, a supplier produced some timing belts that do not meet specification. These timing belts may shred or slip, causing the cam shafts to fall out of timing. Camshafts that are out of timing will set DTC P0341: CMP Sensor and CKP Sensor Incorrect Phase Detected and/or DTC P0369: CMP Sensor Circuit Intermittent Interruption and the engine will run rough. Additionally, shredded timing belts may cause the vehicle to stall and not be able to restart, which increases the risk of a crash.

CUSTOMER NOTIFICATION

Owners of affected vehicles will be sent a notification of this campaign.

Do an iN VIN status inquiry to make sure the vehicle is shown as eligible.

Some vehicles affected by this campaign may be in your new or used vehicle inventory.

Failure to repair a vehicle subject to a recall or campaign may subject your dealership to claims or lawsuits from the customer or anyone else harmed as a result of such failure. To see if a vehicle in inventory is affected by this safety recall, do a VIN status inquiry before selling it.

CORRECTIVE ACTION

Inspect the timing belt and, if necessary, replace the timing belt. If the lot codes are not visible or the timing belt is damaged, a cylinder leak down test may be required and, based on those results, further repairs may be required.

NOTE

Only a small percentage of vehicles are expected to have timing belts that are out of specification. Only order replacement parts after you have identified an out-of-spec timing belt.

PARTS INFORMATION

NOTES

- Parts are applicable to all models unless otherwise noted.

- Only a small percentage of vehicles are expected to have timing belts that are out of specification. Only order replacement parts after you have identified an out-of-spec timing belt.

- Order the engine block and the applicable cylinder head(s) after a damaged engine is identified by completing a cylinder leak-down test.

Timing Belt Replacement

| Part Name | Part Number | Quantity |

| Timing Belt | 14400-R9P-A01 | 1 |

| Timing Belt Idler Bolt | 14551-RCA-A01 | 1 |

| Flange Bolt (10 x 85) | 90002-R70-A00 | 1 |

| Flange Bolt (10 x 60) | 90168-TA1-A00 | 2 |

| Flange Bolt (10 x 105) | 95801-10105-08 | 2 |

Engine Block and Cylinder Head Replacement – Odyssey

| Part Name | Part Number | Quantity |

| Cylinder Block Assembly | 10002-5MR-A10 | 1 |

| Front Cylinder Head Assembly | 10004-5MR-A00 | 1 |

| Rear Cylinder Head Assembly | 10005-5MR-A00 | 1 |

| Self-Locking Nut (10 mm) | 90212-SA5-003 | 6 |

| Exhaust Pipe Gasket | 18212-SA7-003 | 2 |

| Pre-Chamber Gasket | 18393-SDB-A00 | 2 |

| Flange Bolt (12 x 30) | 90161-SHJ-A00 | 8 |

| Flange Bolt (14 x 125) | 90165-TK8-A00 | 2 |

| Flange Bolt (10 x 25) | 90167-SAA-010 | 4 |

| Self-locking Nut (8 mm) | 90212-RCA-A01 | 8 |

| Front Cylinder Head Gasket Kit | 06110-5MR-A01 | 1 |

| Rear Cylinder Head Gasket Kit | 06120-5MR-A01 | 1 |

| Cylinder Block Gasket Kit | 06111-5J6-000 | 1 |

| Washer Bolt (12 x 163) | 90005-PAA-A01 | 12 |

| Washer Bolt (12 x 188) | 90005-5G0-A01 | 4 |

| EGR Gasket Pipe A | 18716-R70-A01 | 1 |

| EGR Gasket Pipe B | 18719-R70-A01 | 1 |

| Exhaust Chamber Gasket (NIPPON LEAKLESS) | 18115-5G0-A01 | 1 |

| O-Ring (5/8″) | 80871-SN7-003 | 1 |

| O-Ring (8 mm) | 80873-ST7-000 | 1 |

| Castle Nut (14 mm) | 90365-STX-A00 | 2 |

| Split Pin (M14) | 90701-S3V-A01 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Split Pin (3.0 x 22) | 94201-30220 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Flange Bolt (10 x 35) | 90163-SDA-A01 | 2 |

| Flange Nut (12 mm) | 90371-SAA-010 | 4 |

| Flange Bolt (10 x 30) | 90163-SDB-A00 | 3 |

| Flange Bolt (12 x 75) | 90163-TA0-A00 | 4 |

| Fuel Joint Pipe Set | 16012-R9P-315 | 1 |

| O-Ring | 91311-5A2-A01 | 1 |

| Injector Clip | 16451-5R1-J01 | 6 |

| Injector Seal Set | 16452-RLV-A00 | 2 |

Engine Block and Cylinder Head Replacement – Pilot

| Part Name | Part Number | Quantity |

| Cylinder Block Assembly | 10002-5J6-A02 | 1 |

| Front Cylinder Head Assembly | 10004-RLV-A00 | 1 |

| Rear Cylinder Head Assembly | 10005-RLV-X00 | 1 |

| Self-Locking Nut (10 mm) | 90212-SA5-003 | 6 |

| Exhaust Pipe Gasket | 18212-SA7-003 | 2 |

| Pre-Chamber Gasket | 18393-SDB-A00 | 2 |

| Flange Bolt (12 x 30) | 90161-SHJ-A00 | 8 |

| Flange Bolt (14 x 125) | 90165-TK8-A00 | 2 |

| Flange Bolt (10 x 25) | 90167-SAA-010 | 4 |

| Self-locking Nut (8 mm) | 90212-RCA-A01 | 8 |

| Front Cylinder Head Gasket Kit | 06110-RLV-000 | 1 |

| Rear Cylinder Head Gasket Kit | 06120-RLV-000 | 1 |

| Cylinder Block Gasket Kit | 06111-5J6-000 | 1 |

| Washer Bolt (12 x 163) | 90005-PAA-A01 | 12 |

| Washer Bolt (12 x 188) | 90005-5G0-A01 | 4 |

| EGR Gasket Pipe A | 18716-R70-A01 | 1 |

| EGR Gasket Pipe B | 18719-R70-A01 | 1 |

| Exhaust Chamber Gasket (NIPPON LEAKLESS) | 18115-5G0-A01 | 1 |

| O-Ring (5/8″) | 80871-SN7-003 | 1 |

| O-Ring (8 mm) | 80873-ST7-000 | 1 |

| Castle Nut (14 mm) | 90365-STX-A00 | 2 |

| Split Pin (M14) | 90701-S3V-A01 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Split Pin (3.0 x 22) | 94201-30220 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Flange Bolt (10 x 35) | 90163-SDA-A01 | 2 |

| Flange Nut (12 mm) | 90371-SAA-010 | 4 |

| Flange Bolt (10 x 30) | 90163-SDB-A00 | 3 |

| Flange Bolt (12 x 75) | 90163-TA0-A00 | 4 |

| Fuel Joint Pipe Set | 16012-R9P-315 | 1 |

| O-Ring | 91311-5A2-A01 | 1 |

| Injector Clip | 16451-5R1-J01 | 6 |

| Injector Seal Set | 16453-R9P-A00 | 2 |

Engine Block and Cylinder Head Replacement – Ridgeline

| Part Name | Part Number | Quantity |

| Cylinder Block Assembly | 10002-5MJ-A00 | 1 |

| Front Cylinder Head Assembly | 10004-5MJ-A00 | 1 |

| Rear Cylinder Head Assembly | 10005-5MJ-A00 | 1 |

| Self-Locking Nut (10 mm) | 90212-SA5-003 | 6 |

| Exhaust Pipe Gasket | 18212-SA7-003 | 2 |

| Pre-Chamber Gasket | 18393-SDB-A00 | 2 |

| Flange Bolt (12 x 30) | 90161-SHJ-A00 | 8 |

| Flange Bolt (14 x 125) | 90165-TK8-A00 | 2 |

| Flange Bolt (10 x 25) | 90167-SAA-010 | 4 |

| Self-locking Nut (8 mm) | 90212-RCA-A01 | 8 |

| Front Cylinder Head Gasket Kit | 06110-RLV-000 | 1 |

| Rear Cylinder Head Gasket Kit | 06120-RLV-000 | 1 |

| Cylinder Block Gasket Kit | 06111-5J6-000 | 1 |

| Washer Bolt (12 x 163) | 90005-PAA-A01 | 12 |

| Washer Bolt (12 x 188) | 90005-5G0-A01 | 4 |

| EGR Gasket Pipe A | 18716-R70-A01 | 1 |

| EGR Gasket Pipe B | 18719-R70-A01 | 1 |

| Exhaust Chamber Gasket (NIPPON LEAKLESS) | 18115-5G0-A01 | 1 |

| O-Ring (5/8″) | 80871-SN7-003 | 1 |

| O-Ring (8 mm) | 80873-ST7-000 | 1 |

| Castle Nut (14 mm) | 90365-STX-A00 | 2 |

| Split Pin (M14) | 90701-S3V-A01 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Split Pin (3.0 x 22) | 94201-30220 | 2 |

| Flange Nut (12 mm) | 90362-SZA-A00 | 2 |

| Flange Bolt (10 x 35) | 90163-SDA-A01 | 2 |

| Flange Nut (12 mm) | 90371-SAA-010 | 4 |

| Flange Bolt (10 x 30) | 90163-SDB-A00 | 3 |

| Flange Bolt (12 x 75) | 90163-TA0-A00 | 4 |

| Fuel Joint Pipe Set | 16012-R9P-315 | 1 |

| O-Ring | 91311-5A2-A01 | 1 |

| Injector Clip | 16451-5R1-J01 | 6 |

| Injector Seal Set | 16452-RLV-A00 | 2 |

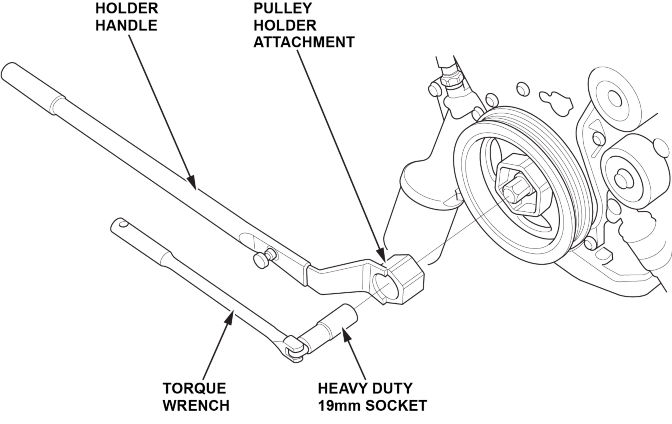

REQUIRED TOOLS

| Part Name | Part Number | Quantity |

| Holder Handle | 07JAB-001020B | 1 |

| 50 mm Offset Holder Attachment | 07MAB-PY3010A | 1 |

| 19 mm Socket | 07JAA-001020A | 1 |

| Cylinder Leak Down Tester | Commercially available | 1 |

REQUIRED MATERIALS

| Material Name | Part Number | Quantity |

Honda Long-Life Antifreeze/Coolant Type 2 Long-Life Antifreeze/Coolant Type 2 | OL999-9011 | 3 |

Honda Genuine Motor Oil 0W-20 Genuine Motor Oil 0W-20 | 08798-9036 | 6 |

| Hondabond HT (1 tube repairs 4 vehicles) | 08718-0004 | 1 |

WARRANTY CLAIM INFORMATION

Timing Belt Inspection

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 1105C3 | Odyssey | 0.5 hr | 6CX00 | L4M00 | A19045A | 14400-R9P-A01 |

| 1105C3 | Pilot | 0.5 hr | 6CX00 | L4M00 | A19045B | 14400-R9P-A01 |

| 1105C3 | Ridgeline | 0.5 hr | 6CX00 | L4M00 | A19045C | 14400-R9P-A01 |

Timing Belt Inspection, Replacement, Diagnosis (Cylinder Leak Down and Valve Timing), and Verify Valve Timing

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 1105C5 | Odyssey | 3.1 hr | 6CX00 | L4M00 | A19045D | 14400-R9P-A01 |

| 1105C5 | Pilot | 3.2 hr | 6CX00 | L4M00 | A19045E | 14400-R9P-A01 |

| 1105C5 | Ridgeline | 3.4 hr | 6CX00 | L4M00 | A19045F | 14400-R9P-A01 |

Timing Belt Inspection, Diagnosis, and Replace the Engine Block and One Cylinder Head

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 1105C6 | Odyssey | 13.6 hr | 6CX00 | L4M00 | A19045G | 14400-R9P-A01 |

| 1105C6 | Pilot 2WD | 12.4 hr | 6CX00 | L4M00 | A19045H | 14400-R9P-A01 |

| 1105C6 | Pilot AWD | 12.4 hr | 6CX00 | L4M00 | A19045I | 14400-R9P-A01 |

| A | Add for AWD | 0.4 hr | ||||

| 1105C6 | Ridgeline 2WD | 12.4 hr | 6CX00 | L4M00 | A19045J | 14400-R9P-A01 |

| 1105C6 | Ridgeline AWD | 12.4 hr | 6CX00 | L4M00 | A19045K | 14400-R9P-A01 |

| A | Add for AWD | 0.4 hr |

Timing Belt Inspection, Diagnosis, and Replace the Engine Block and Two Cylinder Heads

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 1105C7 | Odyssey | 13.9 hr | 6CX00 | L4M00 | A19045L | 14400-R9P-A01 |

| 1105C7 | Pilot 2WD | 12.7 hr | 6CX00 | L4M00 | A19045M | 14400-R9P-A01 |

| 1105C7 | Pilot AWD | 12.7 hr | 6CX00 | L4M00 | A19045N | 14400-R9P-A01 |

| A | Add for AWD | 0.4 hr | ||||

| 1105C7 | Ridgeline 2WD | 12.7 hr | 6CX00 | L4M00 | A19045O | 14400-R9P-A01 |

| 1105C7 | Ridgeline AWD | 12.7 hr | 6CX00 | L4M00 | A19045P | 14400-R9P-A01 |

| A | Add for AWD | 0.4 hr |

Skill Level: Repair Technician

INSPECTION

- Place the vehicle on a lift, and remove the right front wheel.

- Remove the top engine cover.

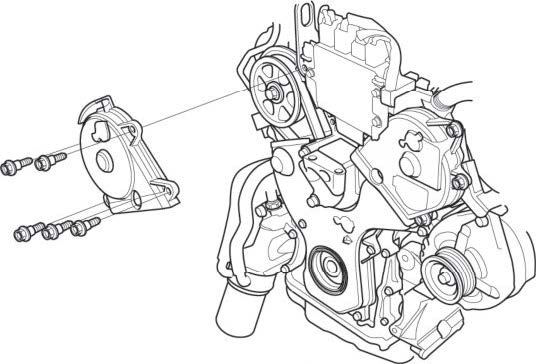

- Remove the rear upper timing belt cover.

3.1 Remove the 5 bolts.

3.2 Remove the rear upper timing belt cover.

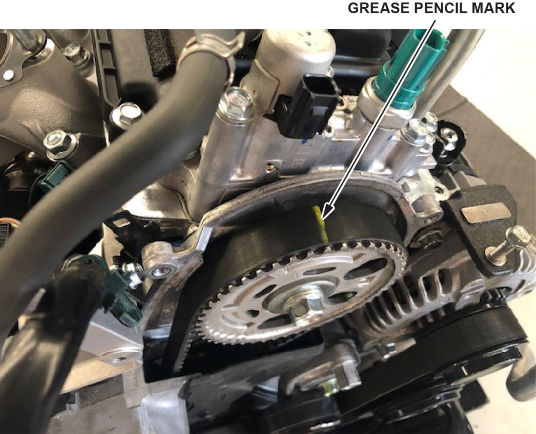

- Mark the side of the timing belt as shown with a grease pen or marker.

- Rotate the engine clockwise until you see the timing belt manufacturing information (lot code) or until the mark you made on the timing belt is visible again.

NOTES

You may need to rotate the engine several times before either the lot code or the mark you made is visible.

- If the lot code is visible, go to step 6.

- If the lot code is not visible, go to TIMING BELT REPLACEMENT.

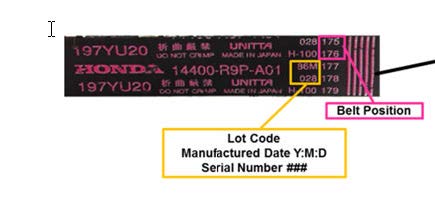

- Check the Lot Code.

-

- If the Lot Code is listed in the table, go to step 7.

- If the Lot Code is not listed in the table, the timing belt is okay, and the inspection is complete. Reassemble the vehicle in the reverse order of removal.

| 85B001 | 85B013 | 85E013 | 85E021 | 85E029 | 85E033 | 85E037 | 85E041 | 85F006 | 85F017 |

| 85F021 | 85F037 | 85F045 | 85F053 | 85G012 | 85G024 | 85G032 | 85G036 | 85G043 | 85G054 |

| 85H004 | 85H012 | 85H024 | 85H052 | 85I017 | 85I032 | 85I037 | 85I040 | 85I044 | 85L013 |

| 85L017 | 85L021 | 85L025 | 85L029 | 85L037 | 85L045 | 85M005 | 85M009 | 85M013 | 85M021 |

| 85N029 | 85N045 | 868039 | 868052 | 86B003 | 86B007 | 86B026 | 86B034 | 86C018 | 86C044 |

| 86C048 | 86I004 | 86I010 | 86I014 | 86J001 | 86J045 | 86J049 | 86J053 | 86K005 | 86K009 |

| 86K013 | 86K025 | 86K029 | 86K033 | 86K039 | 86L016 | 86L028 | 86L032 | 86L040 | 86L044 |

| 86L056 | 86M028 | 86M044 | 86M048 | 86M052 | 86M056 | 86P028 | 86P044 | 86R003 | 86R019 |

| 86R043 | 86R051 | 86S054 | 86T064 | 876006 | 876039 | 87A038 | 87B007 | 87B015 |

- Check the belt position code.

-

- If all of the belt position values are less than 170, the timing belt is okay. Reassemble the vehicle in the reverse order of removal.

- If any of the belt position values are 170 or more, go to TIMING BELT REPLACEMENT.

TIMING BELT REPLACEMENT

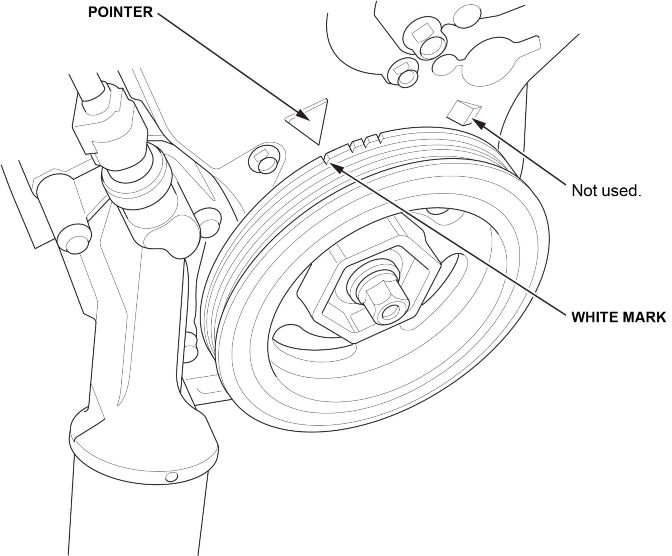

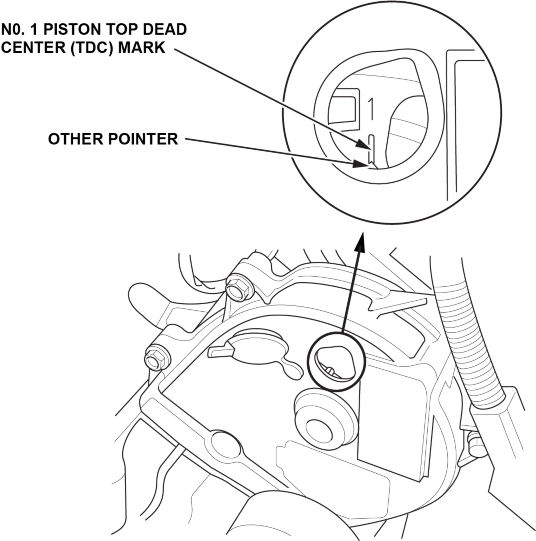

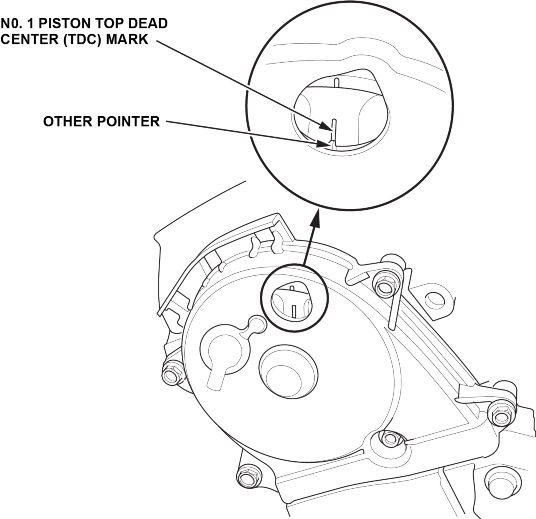

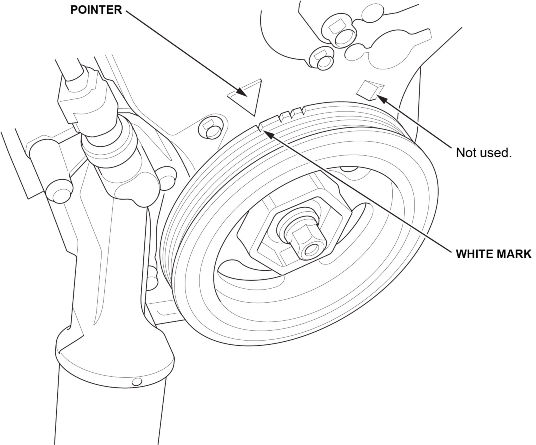

- Turn the crankshaft so its white mark on the crankshaft pulley lines up with the pointer.

NOTE

The other pointer is not used.

- Install the upper timing belt cover, and check that the No. 1 piston top dead center (TDC) mark on the front camshaft pulley and the pointer on the front upper covers are aligned.

NOTES

- If the marks are not aligned, rotate the crankshaft 360 degrees, and recheck the camshaft pulley mark.

- If the marks still do not align, remove the original timing belt, install the new timing belt, then check the alignment again.

Front

Rear

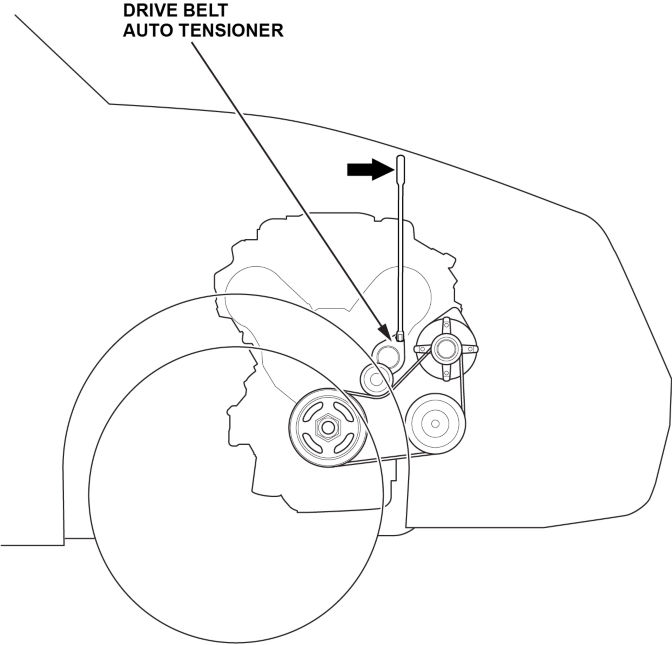

- Remove the drive belt.

- Partially remove the right side splash shield to gain access to the lower half of the engine.

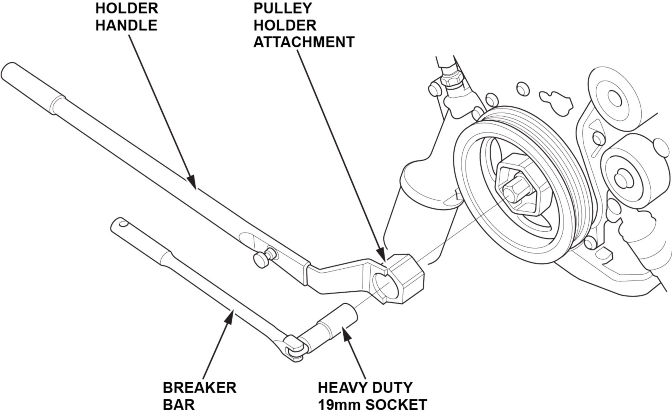

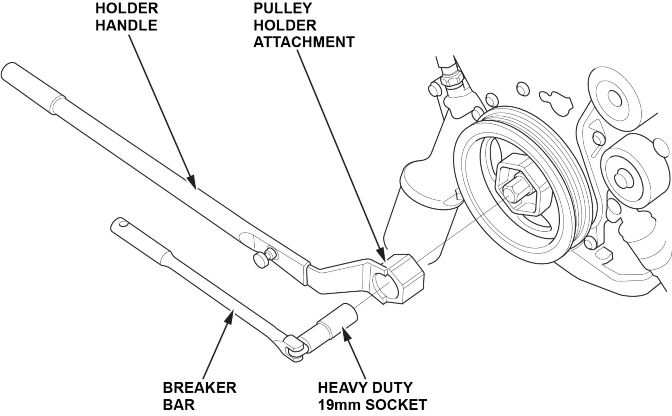

- Remove the crankshaft pulley.

5.1 Hold the pulley with the holder handle and the crankshaft pulley holder attachment.

5.2 Remove the bolt with a heavy duty 19 mm socket and a breaker bar, then remove the crankshaft pulley.

- Lift and support the engine with a jack and a wood block under the oil pan.

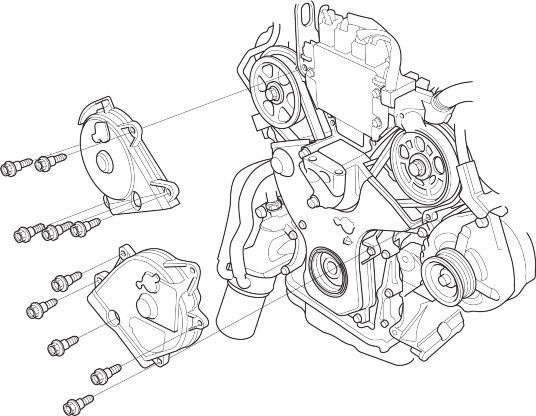

- Remove the upper part of the side engine mount.

7.1 Disconnect the ground cable.

7.2 Remove the harness clamp bracket and the upper half of side engine mount bracket.

NOTE

You do not need to move the VSA modulator control unit.

- Remove the upper covers.

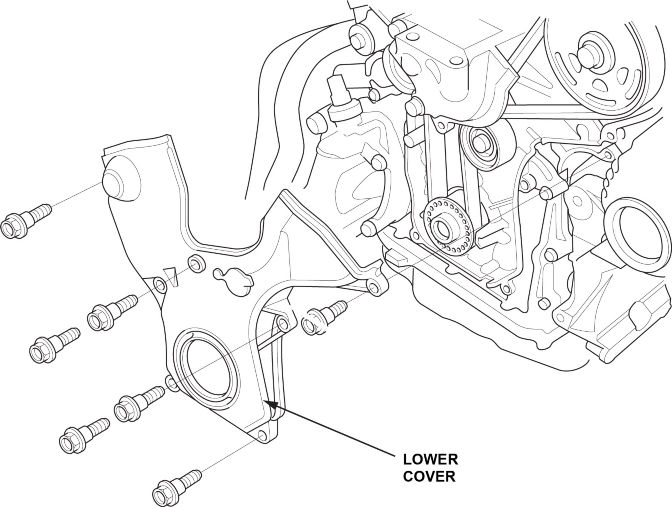

- Remove the lower cover.

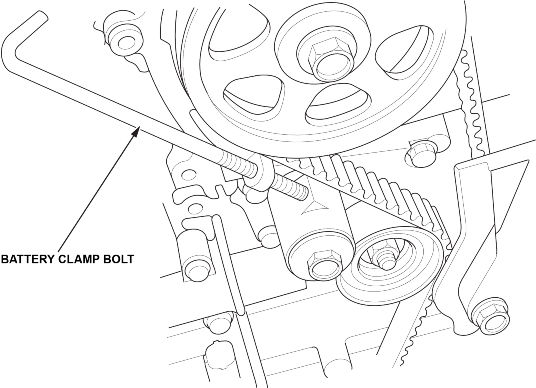

- Hold the timing belt adjuster.

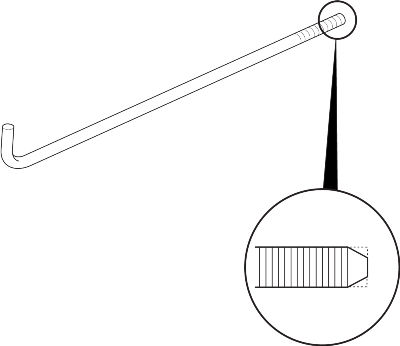

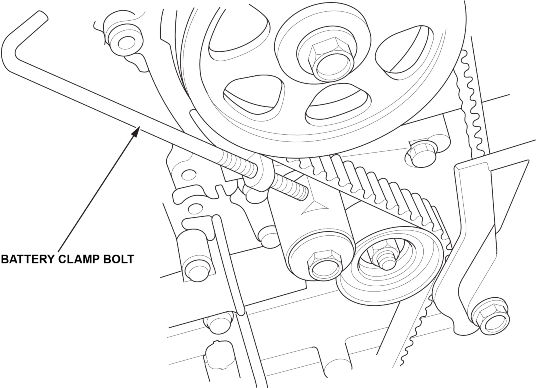

10.1 Remove one of the battery clamp bolts from the battery tray, and grind the end of it as shown.

10.2 Thread the battery clamp bolt in as shown to hold the timing belt adjuster in its current position. Tighten it by hand.

NOTICE

Do not tighten the bolt with a wrench.

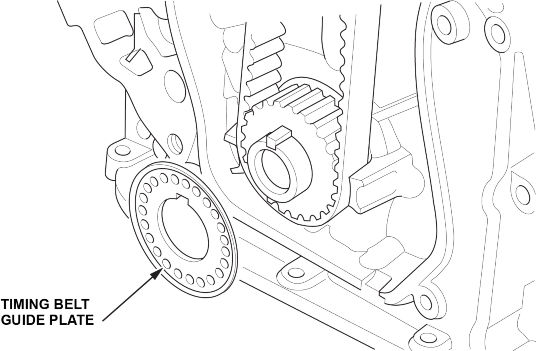

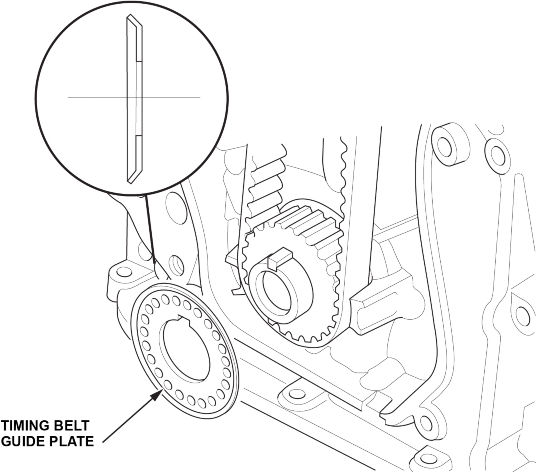

- Remove the timing belt guide plate.

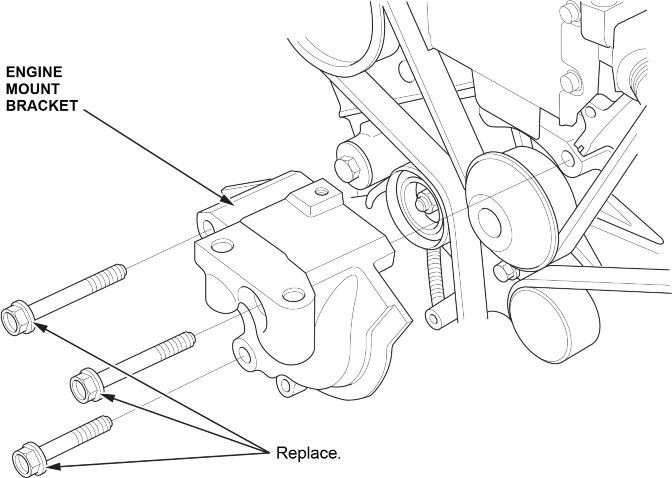

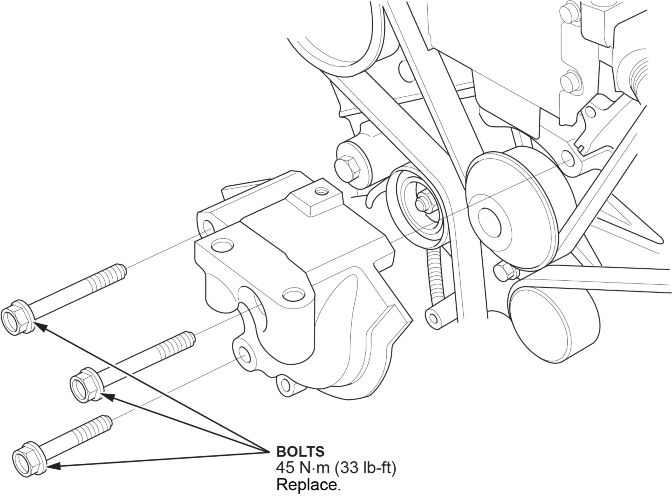

- Remove the lower half of the side engine mount bracket.

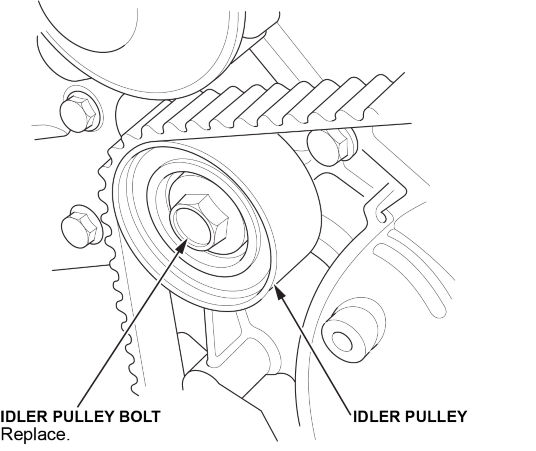

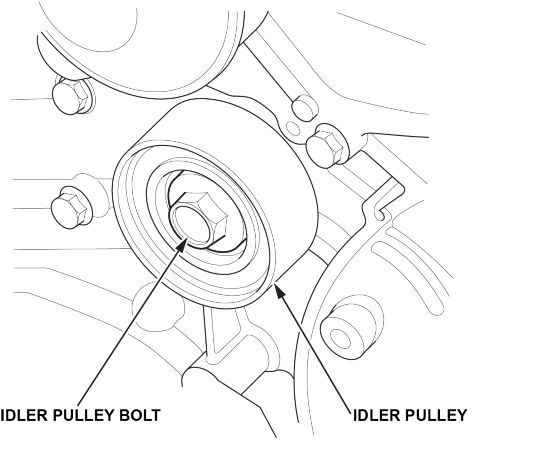

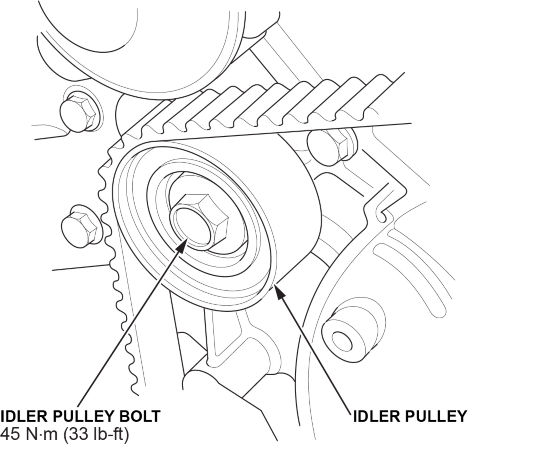

- Remove the idler pulley bolt and the idler pulley, then remove the timing belt.

- Check the timing marks are still in the proper position as mentioned in steps 1 and 2.

- Loosely install the idler pulley with a new idler pulley bolt so the pulley can move, but does not come off.

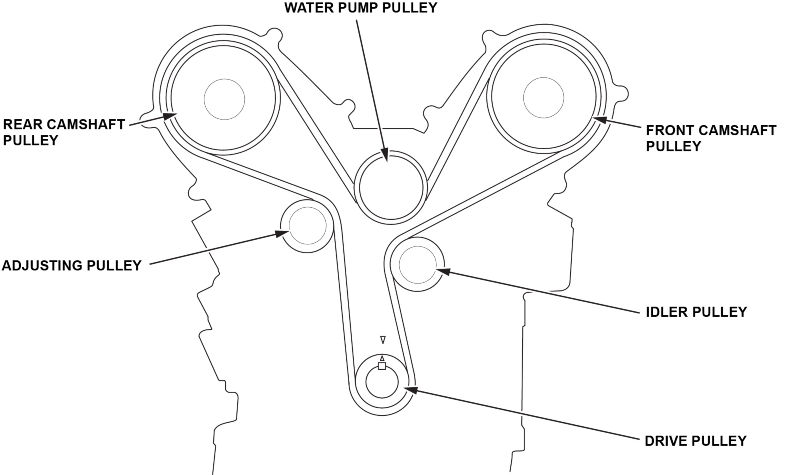

- Install the timing belt in a counter-clockwise sequence starting with the drive pulley:

16.1 Drive Pulley

16.2 Idler Pulley

16.3 Front Camshaft Pulley

16.4 Water Pump Pulley

16.5 Rear Camshaft Pulley

16.6 Adjusting Pulley

NOTE

If the timing belt auto-tensioner has extended and the timing belt cannot be installed, do the timing belt auto tensioner installation procedure. Refer to the service information.

- Torque the idler pulley bolt to 45 N·m (33 lb-f).

- Remove the battery clamp bolt.

- Check the cam timing and do a cylinder leak down test.

NOTE

The following steps will determine if there was any valve to piston contact requiring the replacement of the cylinder block and one or both cylinder heads.

19.1 Remove all the spark plugs.

19.2 Do the cylinder leak down test. For information about the cylinder leak down test, refer to the following:

-

- See the Tech2Tech video titled Cylinder Leak Down Testing

- See the Online University Self-Study Module WAENC10 Pump Theory and Cylinder Performance Testing

NOTES

- Rotate the engine only in a clockwise direction.

- Confirm each cylinder is tested at TDC.

- A good cylinder should have less than 10% cylinder leakage.

19.3 If the cylinder leak down test results show that all six cylinders have a leak down rate of 10% or less, go to step 20 and finish installing the timing belt.

19.4 If the cylinder leak down test results show that at least one cylinder has a leak down rate that is more than 10%, and the leak is from the intake or exhaust valves, replace the short block and the cylinder head(s) where the leak is coming from. Refer to the service information.

NOTE

If the leak is coming through the crankcase, this bulletin does not apply. Continue with normal troubleshooting.

- Install the lower half of the side engine mount bracket using new bolts. Torque the bolts to 45 N·m (33 lb-f).

NOTE

Make sure the lower half of the side engine mount bracket is installed and the new bolts are torqued to specification before installing the upper half of the engine mount.

- Install the timing belt guide plate as shown.

- Install the timing belt covers:

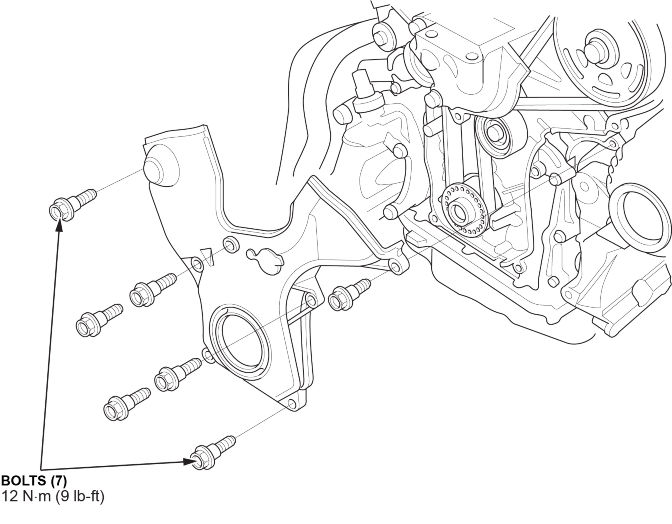

22.1 Install the lower cover, and torque the bolts to 12 N·m (9 lb-ft).

22.2 Install the upper covers, and torque the bolts to 12 N·m (9 lb-ft).

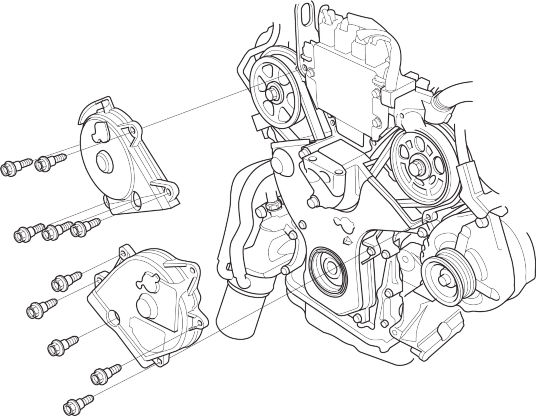

- Install the upper half of the side engine mount bracket using new bolts:

23.1 Loosely install the upper half of the side engine mount bracket using new bolts.

23.2 Connect the ground cable.

23.3 Remove the jack and wood block.

23.4 Tighten the side engine mount bracket mounting bolts in the sequence shown.

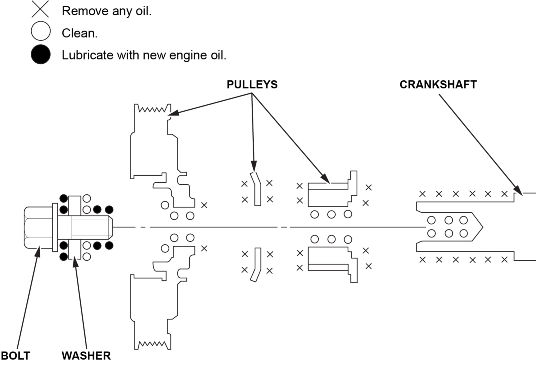

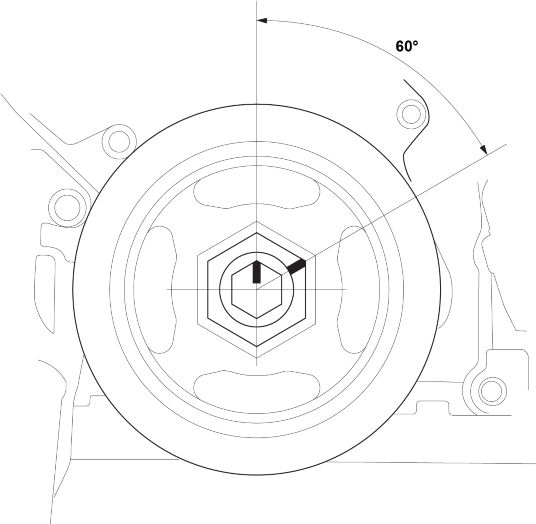

- Install the crankshaft pulley.

24.1 Remove any oil and clean the pulleys, the crankshaft, the bolt, and the washer. Lubricate with new engine oil as shown.

24.2 Install the crankshaft pulley.

24.3 Hold the pulley with the holder handle and the pulley holder attachment (50 mm offset). Torque the bolt to 65 N·m (48 lb-ft).

NOTE

Do not use an impact wrench.

24.4 Tighten the bolt an additional 60°.

- Check the camshaft timing.

25.1 Rotate the crankshaft pulley about 6 turns clockwise so the timing belt positions itself on the pulleys.

25.2 Turn the crankshaft pulley so the white mark lines up with the pointer.

NOTE

The other pointer is not used.

25.3 Check the camshaft pulley marks.

NOTES

If the marks are not aligned, rotate the crankshaft one full turn and recheck the camshaft pulley mark.

- If the camshaft pulley marks are at TDC, go to the next step.

- If the camshaft pulley marks are not at TDC, remove the timing belt and restart the installation procedure at step 16.

- Install the drive belt tensioner.

- Install the splash shield.

- Install the passenger’s side front wheel and torque the nuts to 127 N·m (94 lb-ft) for 14 mm wheel bolts, or 108 N·m (80 lb-ft) for 12 mm wheel bolts.

- Do the CKP learn procedure.

END

9 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| ACURA | MDX | 2018-2019 |

| ACURA | RLX | 2019 |

| ACURA | RLX HYBRID | 2019 |

| ACURA | TLX | 2019 |

| HONDA | ODYSSEY | 2019 |

| HONDA | PILOT | 2018-2019 |

| HONDA | RIDGELINE | 2019 |

25 Associated Documents

DEFECT INFORMATION REPORT

RMISC-19V298-2749.pdf 140.784KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 UPDATE: Revision for SB 19-026, Safety Recall: 3.5L V6 Timing Belt

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 Timing Belt (14400-R9P-A01) Inspection

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – April 12, 2019 Safety Recall:18-19 MDX, 2019 TLX 3.5L, RLX, and RLX Sport Hybrid Timing Belt

RCMN-19V298-0918.pdf 154.618KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-1132.pdf 1742.547KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 UPDATE: Revision for SB 19-026, Safety Recall: 3.5L V6 Timing Belt

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – April 12, 2019

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 UPDATE: Revision for SB 19-026, Safety Recall: 3.5L V6 Timing Belt

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – April 12, 2019

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-6640.pdf 1742.301KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – April 12, 2019 Safety Recall:18-19 Pilot and 2019 Odyssey and Ridgeline Timing Belt Inspectiion

RCMN-19V298-3827.pdf 150.842KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-6771.pdf 2639.066KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-1201.pdf 2642.871KB

Loading...

Loading...

Recall Acknowledgement

RCAK-19V298-2455.pdf 382.865KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-8221.pdf 2639.066KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V298-3465.pdf 2642.87KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 Timing Belt (14400-R9P-A01) Inspection

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 04 12 2019 UPDATE: Revision for SB 19-045, Safety Recall: 3.5L V6 Timing Belt

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V298-6327.PDF 218.296KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577) – 19V-298 Owner Notification Letter (L4M) – 2019 Odyssey 3.5L V6 Timing Belt 6-7-2019

RCONL-19V298-6703.pdf 461.591KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577) – 19V-298 Owner Notification Letter (Z4L) – 2018-19 MDX 3.5L V6 Timing Belt 6-7-2019

RCONL-19V298-8194.pdf 378.58KB

Loading...

Loading...

Statement by American Honda Regarding Timing Belt Recall: 2018-2019 Honda Pilot and Acura MDX; 2019 Honda Odyssey, Honda Ridgeline, Acura TLX, Acura RLX and RLX Sport Hybrid

RMISC-19V298-7288.pdf 106.091KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-2

RCLQRT-19V298-3329.PDF 211.153KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-3

RCLQRT-19V298-0796.PDF 211.259KB

Loading...

Loading...

Recall Quarterly Report #3, 2019-4

RCLQRT-19V298-8626.PDF 211.353KB

Loading...

Loading...

Latest Recalls Documents

- Mobil 1 Extended Performance full-synthetic motor oil 0W-20 helps protect critical engine parts for up to 20,000 miles between oil changes,* controlling oxidation to prevent oil breakdown and maintaining excellent viscosity

- Utilizes Mobil 1’s Triple Action+ Formula to combine outstanding engine performance, protection, and cleanliness with the added benefit of power

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Helps extend engine life by working to prevent damaging deposits and sludge buildup

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -40 degrees F)

- 3X Stronger than the leading full synthetic*

- 10X Better high stress performance**

- 20,000 miles between oil changes***

- Approved and Licensed Specifications: Exceeds API SP/SN PLUS/SN/SM |ILSAC GF-6 | GM dexos1 Gen 3 | Meets engine test requirements of Chrysler MS 6395 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Viscosity breakdown as measured in Kurt Orbahn test on 5W-30 grade |**As measured in Seq IX test under high load/torque conditions vs. API SP test limits | ***Or one year, whichever comes first

- 6X better wear protection on critical engine parts than industry standards**

- 1.3X better sludge protection than industry standards*

- 3X Stronger against viscosity breakdown than leading full synthetic^

- Protection for 10,000 miles between oil changes

- Meets or exceeds the following specifications: API SP/SN PLUS/SN | ILSAC GF-6 | GM dexos1 Gen 3 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Full synthetic 0W-20 motor oil that is made with natural gas and designed to maximize engine protection

- Backed by a 15,000-mile protection guarantee* to protect your pursuit of every mile

- Provides better fuel economy (based on the latest industry standards)

- Keeps pistons cleaner than the toughest industry standard (based on Sequence IIIH results)

- Provides unsurpassed wear protection (based on Sequence IVA wear test using SAE 5W-30)

- Mobil 1 High Mileage full-synthetic motor oil 0W-20 is designed for engines with over 75,000 miles to go up to 10,000 miles between oil changes.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanliness

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -30 degrees F)

- Mobil 1 is specially formulated to help remove sludge and lower engine temperatures

- Advanced protection against the four main causes of engine breakdown: wear friction heat and deposits

- Full synthetic 0W-20 formula offers 24X stronger protection against engine-killing contaminants than the leading full synthetic motor oil

- 40% better wear protection vs. industry standards as tested in the Sequence IVB engine test

- 25% better deposit protection with superior engine cleaning detergents as tested in the GMOD engine test

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN, GM dexos 1 Gen 3

- Our most advanced full synthetic 0W-20 engine oil, designed for unbeatable engine protection*

- Pennzoil Ultra Platinum comes with a 20-year, 750,000 mile warranty** to protect your engine and give you peace of mind to drive every mile as hard as you can

- Made with natural gas

- Outstanding performance in extreme temperatures

- Designed for high-performance engines, it helps protect engines from loss of power

- The information below is per-pack only

- Mobil 1 Extended Performance High Mileage full-synthetic motor oil 0W-20 is designed for engines with over 75,000 miles to go up to 20,000 miles between oil changes.*

- Utilizes Mobil 1’s Triple Action+ Formula to combine outstanding engine performance, protection, and cleanliness with the added benefit of power

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -40 degrees F)

- Phosphorus Replacement Technology to help extend the life of the emission system

- Reduces leaks, oil burnoff and power robbing deposits

- 15,000 miles between oil changes*

- Meets or exceeds the following specifications: API SP/SN PLUS/SN/SM | ILSAC GF-6 | Meets engine test requirements of Chrysler MS 6395 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A2

- Or one year, whichever comes first

- Full synthetic formula is engineered with Enhanced MaxLife Technology to prevent engine breakdown in vehicles with over 75,000 miles

- Formulated with seal conditioners to prevent and treat oil leaks, Valvoline Full Synthetic High Mileage minimizes oil consumption and maximizes engine life

- 50% better wear protection than the industry standard and 25% extra defense against deposits, sludge, corrosion and rust

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN

- American made and formulated, from the Original Motor Oil brand trusted for more than 150 years

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.