| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10108323

Manufacturer Communication Number: A12-089

Summary

SERVICE BULLETIN – AMERICAN HONDA IS EXTENDING THE WARRANTY COVERAGE ON THE PISTON RINGS AND PISTONS FOR 201011 CR-V 2WD AND 4WD TO 8 YEARS FROM THE ORIGINAL DATE OF PURCHASE OR 125,000 MILES, WHICHEVER COMES FIRST.

IS EXTENDING THE WARRANTY COVERAGE ON THE PISTON RINGS AND PISTONS FOR 201011 CR-V 2WD AND 4WD TO 8 YEARS FROM THE ORIGINAL DATE OF PURCHASE OR 125,000 MILES, WHICHEVER COMES FIRST.

A12-089

March 31, 2017

06118 Version 7

Warranty Extension: Sticking Rings Resulting in High Engine Oil Consumption

Supersedes 12-089, Sticking Rings Resulting in Unusually High Engine Oil Consumption, dated April 20, 2016; see Revision Summary

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2010–11 | CR-V | ALL | Check the iN VIN status eligibility |

REVISION SUMMARY

Under REQUIRED MATERIALS, the oil was changed to Full Synthetic Engine Oil, P/N 08798-9063.

BACKGROUND

American Honda is extending the warranty coverage on the Piston Rings and Pistons for 2010–11 CR-V 2WD and 4WD to 8 years from the original date of purchase or 125,000 miles, whichever comes first.

is extending the warranty coverage on the Piston Rings and Pistons for 2010–11 CR-V 2WD and 4WD to 8 years from the original date of purchase or 125,000 miles, whichever comes first.

The warranty extension does not apply to any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded, or similar tittle under any state’s law. To check for vehicle eligibility, you must do a VIN status inquiry.

CUSTOMER NOTIFICATION

Owners of affected vehicles will receive a notification of this warranty extension. Do an iN VIN status inquiry to make sure the vehicle is shown as eligible.

SYMPTOM

The engine oil level is low on the dipstick, and the oil warning light may come on in rare high oil consumption situations.

POSSIBLE CAUSES

Under certain specific circumstances the engine may create deposits on the oil control rings, which may lead to increased oil consumption when all of the following conditions occur simultaneously on a regular and prolonged basis:

- The engine is cold (not warmed up to operating temperature)

- Hard acceleration while the engine is cold

- The fuel used has an unusually high concentration of particles – Honda

recommends using Top Tier gas that contains detergents to prevent deposits. For more information about Top Tier gas, go to www.toptiergas.com.

recommends using Top Tier gas that contains detergents to prevent deposits. For more information about Top Tier gas, go to www.toptiergas.com.

All these conditions happening at the same time is rare, but if they do, deposits may form over years of driving. If the oil control rings begin to stick because of the deposits, the customer may subsequently complain about excessive oil consumption.

CORRECTIVE ACTION

Do the procedure under DIAGNOSIS and based on your results, replace all of the engine pistons and piston rings if necessary.

Service Advisor: Talk to the customer about the many factors contributing to oil consumption. Remind him or her that with less frequent service intervals for modern engines, it’s not uncommon to add oil between services. Therefore, it’s a good idea to check the engine oil regularly (as recommended in the owner’s manual) and add oil as necessary.

PARTS INFORMATION

| Part Name | Part Number | Quantity |

| BOLT, CONNECTING ROD (Up to 8 as required after measurements) | 13204-RBB-004 | 8 |

| BOLT, WASHER, 11×176 (Up to 10 as required after measurements) | 90005-RNA-A01 | 10 |

| BOLT, FLANGE 12X40 (Side engine mount) | 95701-12040-08 | 2 |

| Drain plug washer | 94109-14000 | 1 |

| GASKET, Cylinder Head | 12251-R40-A01 | 1 |

| GASKET, SET | 12030-R44-A00 | 1 |

| GASKET, Exhaust Flexible ( Catalytic to A pipe) | 18229-SWA-305 | 1 |

| HondaBond HT ( 1 tube repairs 5 vehicles ) | 08718-0004 | 1 |

Honda Coolant Type 2 ( 1 gallon will be used to top off 2 vehicles ) Coolant Type 2 ( 1 gallon will be used to top off 2 vehicles ) | OL999-9011 | 1 |

Honda Motor Oil, Full Synthetic 0W-20 ( 6 quarts of oil to beused ) Motor Oil, Full Synthetic 0W-20 ( 6 quarts of oil to beused ) | 08798-9063 | 6 |

| Nut, Flange (Side engine mount) | 90213-S5A-003 | 1 |

| Oil Filter | 15400-PLM-A02 | 1 |

| O-Ring ( At oil pump ) | 91301-R40-A01 | 1 |

| O-Ring, Chain Case | 91302-PNA-004 | 1 |

| Oil Seal, Control Valve ( O-ring at VTC Valve assembly ) | 15832-PNA-023 | 1 |

| Packing A, Intake Manifold | 17115-R40-A01 | 4 |

| Piston SET A (STD) (Dealer must determine how many to order) | 13010-R40-A00 | 4 |

| Piston SET B (STD) (Dealer must determine how many to order) | 13020-R40-A00 | 4 |

| Ring Set (STD) | 13011-R44-A01 | 4 |

TOOL INFORMATION

| Part Name | Part Number | Quantity |

| Camshaft Lock Pin Set | 07AAB-RWCA120 | 1 |

| Crank Pulley Holder | 07AAB-RJAA100 | 1 |

| Engine Hanger | AART1256 | 1 |

| Handle 6-25-660L | 07JAB-001020B | 1 |

| Gasket Remover/Pan Separator | LIL50190 | 1 |

| Piston Ring Expander | Snap-On PRS8 or equivalent | 1 |

| Piston Ring Compressor | SCP1287 or equivalent | 1 |

| 1/2 in. Drive Torque Angle Gauge | BLMBLDAG001 or TA360 | 1 |

NOTE: These Items can be purchased through the Honda Tool & Equipment Program 888-424-6857.

Tool & Equipment Program 888-424-6857.

DIAGNOSIS

- Do an engine oil consumption test. Refer to the Job Aid Engine Oil Consumption Test.

- Review the results of the engine oil consumption test.

- Based on the test results, if the engine is consuming an unusually high amount of oil, contact your DPSM for approval, then go to REPAIR PROCEDURE.

- Based on the test results, if the engine is consuming a normal amount of engine oil, the vehicle is OK. Explain to the customer that the vehicle is OK, and that the consumption of oil is within a normal range.

NOTE: Remind the customer to regularly check the engine oil level every time they fill the fuel tank. Modern engines require less frequent oil changes, which may impact the amount of oil used between oil changes.

REPAIR PROCEDURE

This procedure is an outline form that you can also use as a checklist for the repair. For details on the procedures noted, refer to the appropriate service manual, or view them online.

- Engine Oil Replacement

- Battery Terminal Disconnection and Reconnection

- Fuel Pressure Relieving

- Coolant Replacement

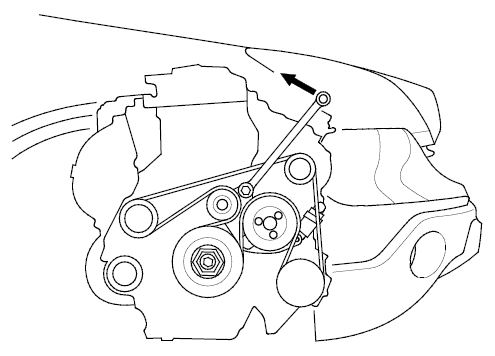

- Drive Belt Removal/Installation

- Intake Manifold Removal and Installation

- Warm Up TWC Removal/Installation

Note: Disconnect TWC at the A-pipe at TWC.

- Fuel Line/Quick-Connect Fitting Removal

- Cylinder Head Removal

- Cam Chain Removal

- Rocker Arm Assembly Removal

- Valve Adjustment

- Oil Pan Installation

- ECM Idle Learn Procedure

NOTE:

- Before starting work, make sure to order the correct number of “A” and “B” pistons. Refer to ORDERING PISTONS on page 31 of this bulletin.

- Use fender covers to avoid damaging painted surfaces.

- To avoid damaging the wires and terminals, unplug the wiring connectors carefully while holding the connector portion.

- To avoid damaging the cylinder head, wait until the engine coolant temperature drops below 100°F (38°C) before loosening the cylinder head bolts. If needed, connect the HDS to the DLC, and monitor ECT SENSOR 1.

- Mark all wiring and hoses to avoid misconnection. Also, be sure that they do not contact any other wiring or hoses, or interfere with any other parts.

- Make sure that Service Bulletin 11-049, Product Update: Software Update to Improve Fuel Injector and VTC Timing is complete by checking the iN VIN status.

NOTE: If you do not confirm software update has been completed, your warranty claim could be debited.

- Put the vehicle on a lift.

- Relieve the fuel pressure.

- Do the battery terminal disconnection procedure.

- Drain the engine oil

- Drain the engine coolant.

NOTE: Use a clean container to recover coolant for re-use.

- Remove the drive belt.

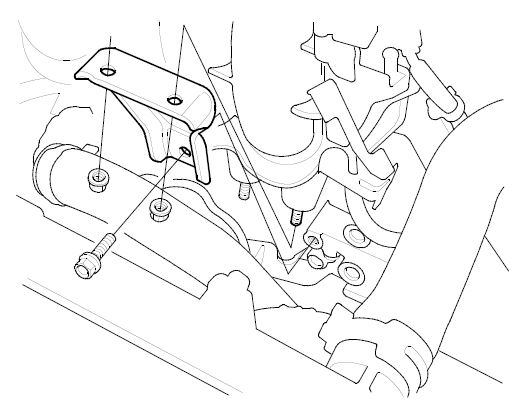

- Remove the intake manifold. Remove the intake manifold bracket lower bolt.

NOTE: It is not necessary to remove the two nuts or the bracket from the intake manifold.

- Unbolt TWC at the A-Pipe, leaving the TWC mounted to the cylinder head assembly.

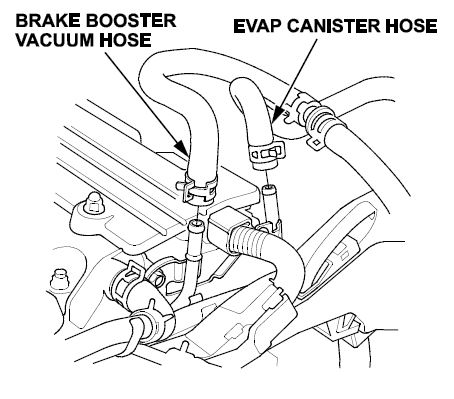

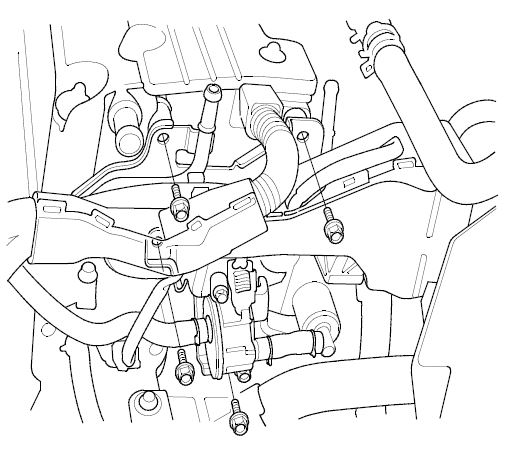

- Disconnect the brake booster vacuum and EVAP canister hoses.

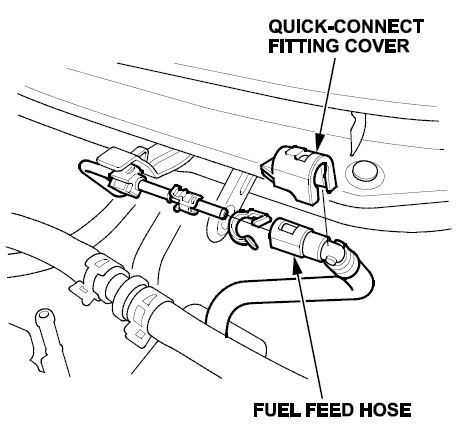

- Remove the quick-connect fitting cover, then disconnect the fuel feed hose.

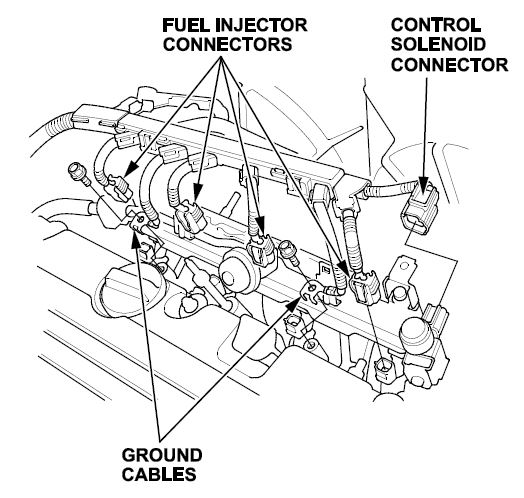

- Disconnect the four fuel injector connectors, the control solenoid valve connectors, and disconnect the ground cables.

- Remove the four bolts securing the EVAP canister purge valve bracket.

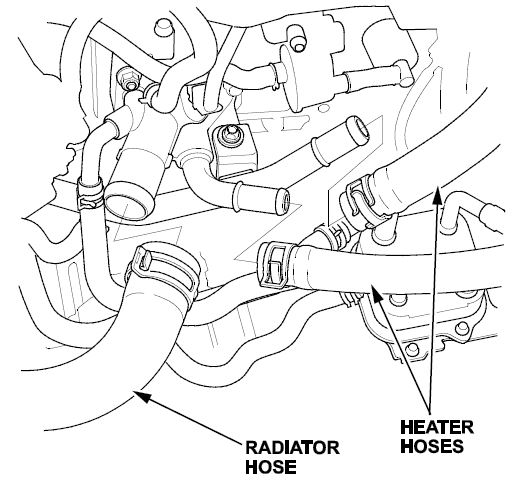

- Disconnect the radiator hoses and the heater hoses. Disconnect the ATF warmer bypass hose (if equipped)

NOTE: The second radiator hose is connected to the thermostat and is not shown.

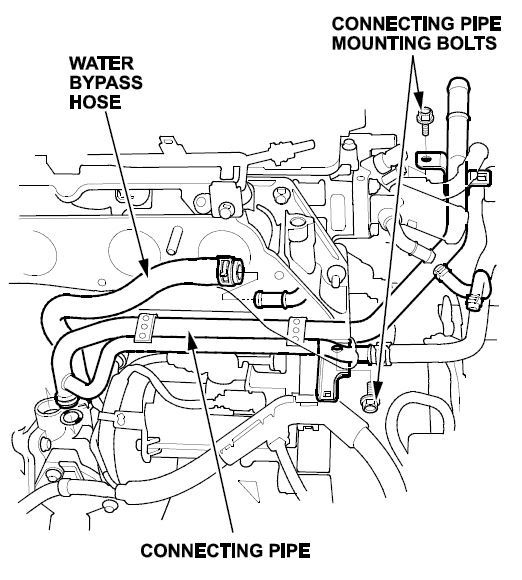

- Remove the two bolts securing the connecting hose. Disconnect the water bypass hose.

- Support the engine with a floor jack, then remove the right side engine mount.

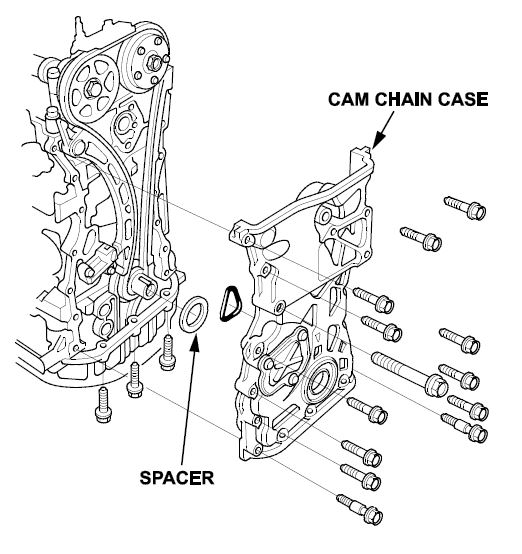

- Remove the front cam chain cover and the cam chain.

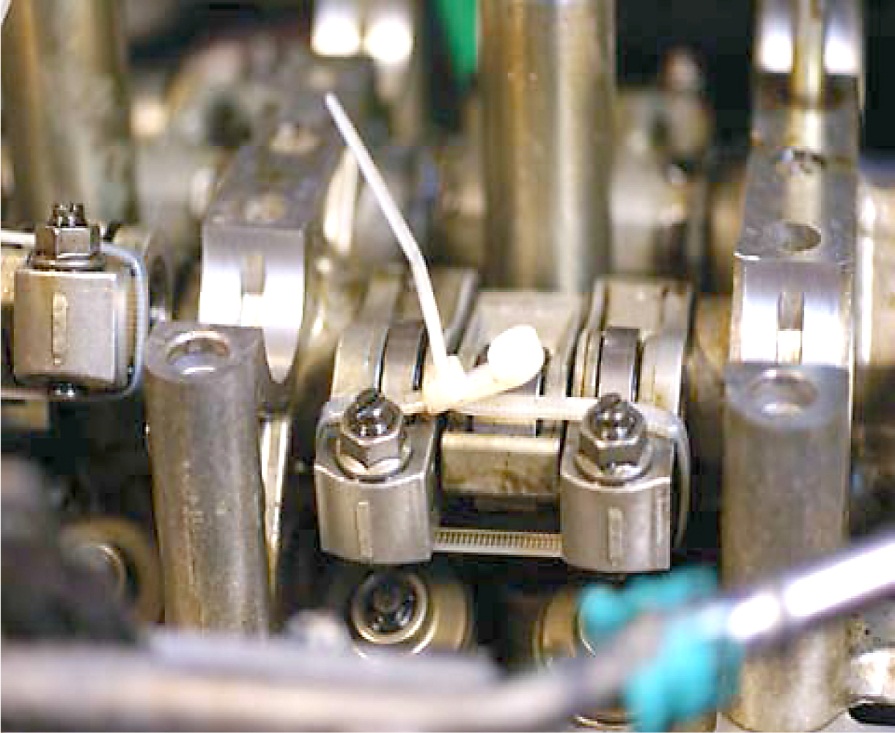

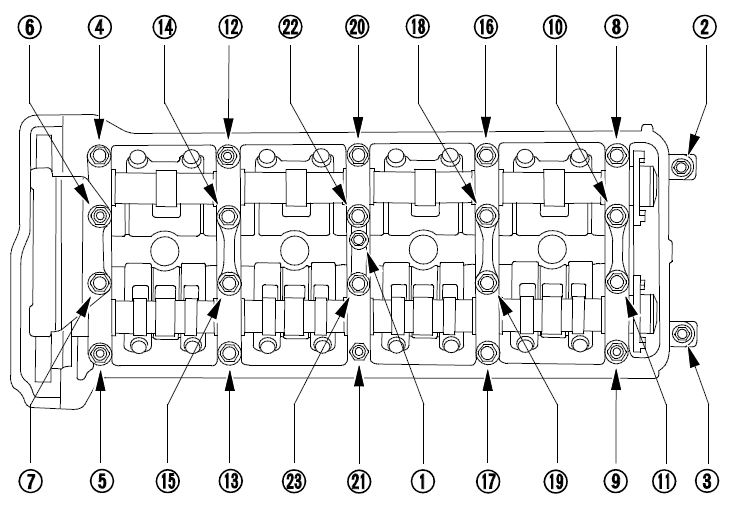

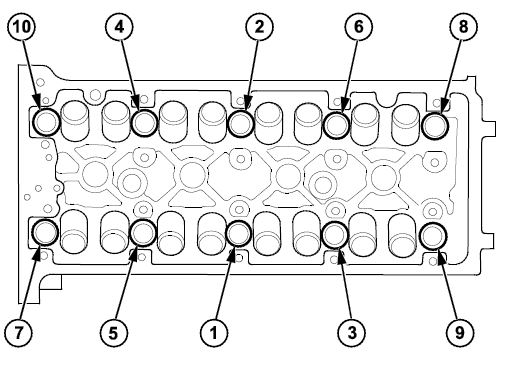

- To prevent damage to the camshafts, loosen the bolts, in sequence, two turns at a time. Remove the camshaft holder bolts, Remove the rocker arm assembly and both cam shafts.

NOTE: Bolt #1 is not on all engines.

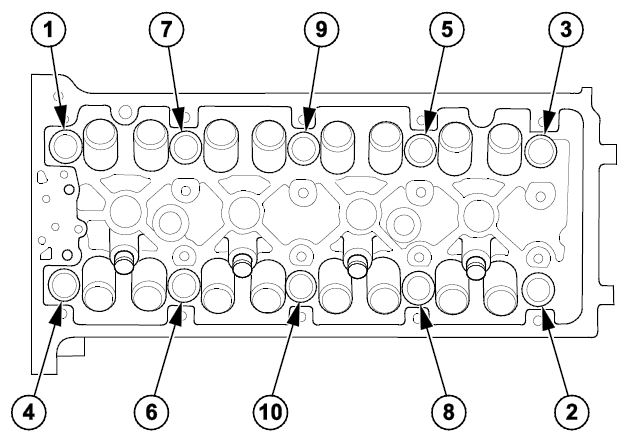

- To prevent warpage, loosen the bolts in sequence 1/3 turn at a time; repeat the sequence until all the bolts are loosened, Remove the cylinder head bolts.

- Remove the cylinder head with the catalytic converter attached.

NOTE: Be careful not to lose the lost motion springs.

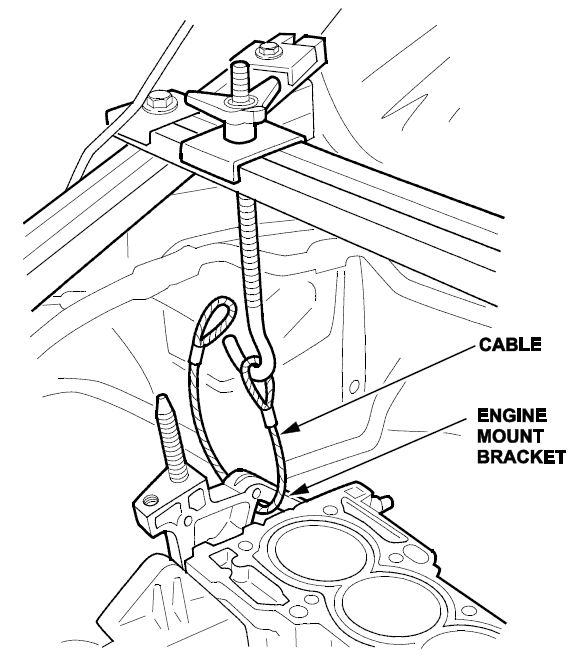

- Raise the vehicle on the lift. Attach the engine hanger.

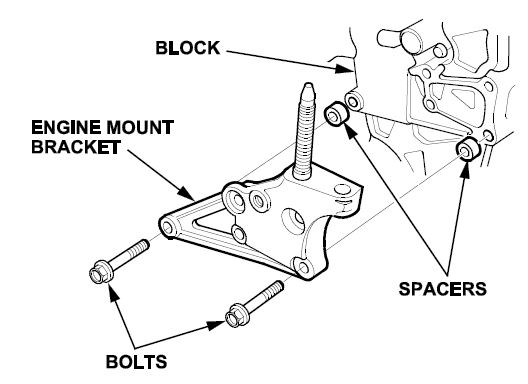

- Attach the engine mount bracket to the engine block with two 10 mm spacers and two (10 mm diameter) bolts that are about 40 mm and 55 mm long.

NOTE: You can find spacers in the engine hanger kit.

- Assemble the engine hanger.

- Loop the wire around the engine mount bracket and attach the looped ends to the hook.

- Raise the engine with a floor jack just enough to relieve the engine weight from the lower engine bracket. Tighten the hook so that when you lower the floor jack, the engine is suspended in place.

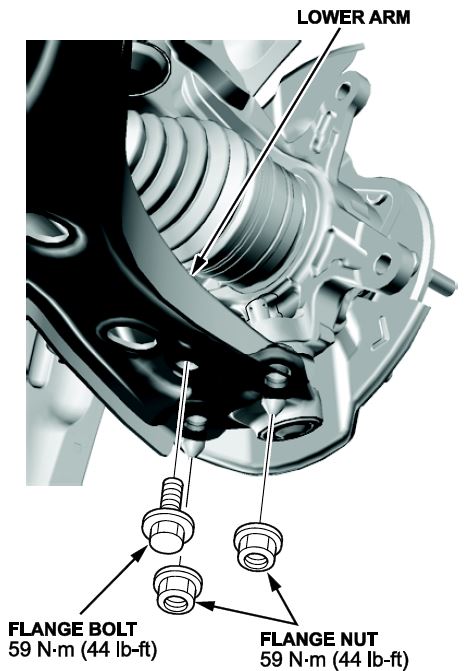

- Disconnect the lower ball joint from the lower control arm

- Drive the inboard joint off of the intermediate shaft using a drift punch and a hammer, then move the shaft out of your way

- Remove the oil pan.

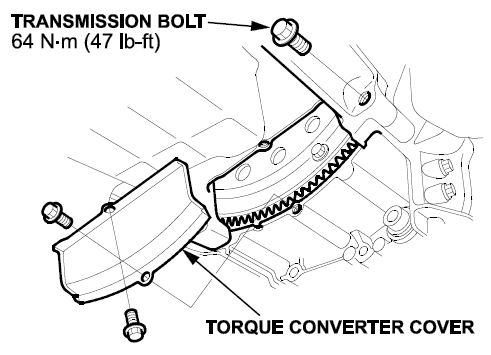

- Remove the torque converter cover, then remove the two bolts securing the oil pan to the transmission.

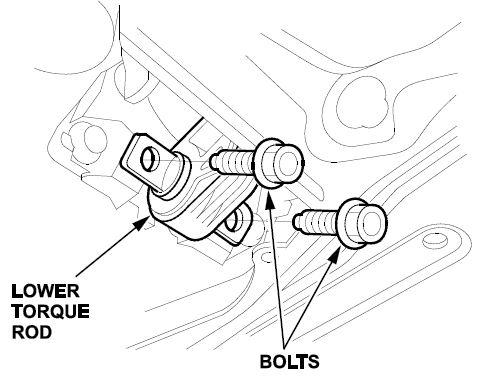

- Remove the lower torque rod mounting bolts.

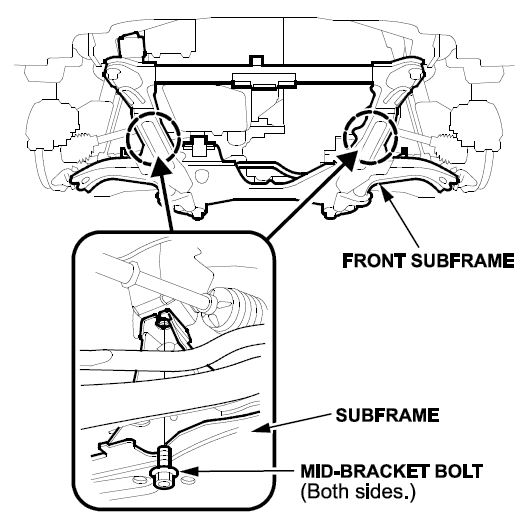

- Loosen the mid-stiffener mounting bolt on both slides.

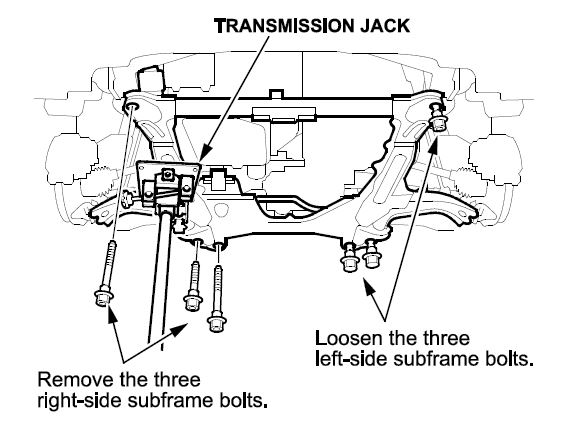

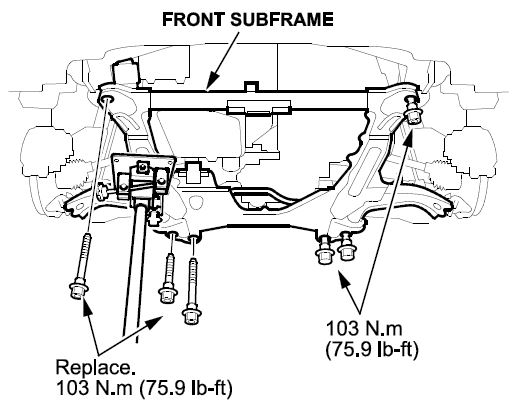

- Place a transmission jack under the right side of the subframe and remove the subframe bolts on the right side.

- Loosen the subframe mounting bolts on the left side so that you can lower the subframe about 20 mm.

- Remove the lower torque rod bracket.

- Remove the bolts securing the oil pan.

NOTE: The engine wobbles as it is being lifted, so make sure nothing is stressed or damaged such as the A/C lines or pump

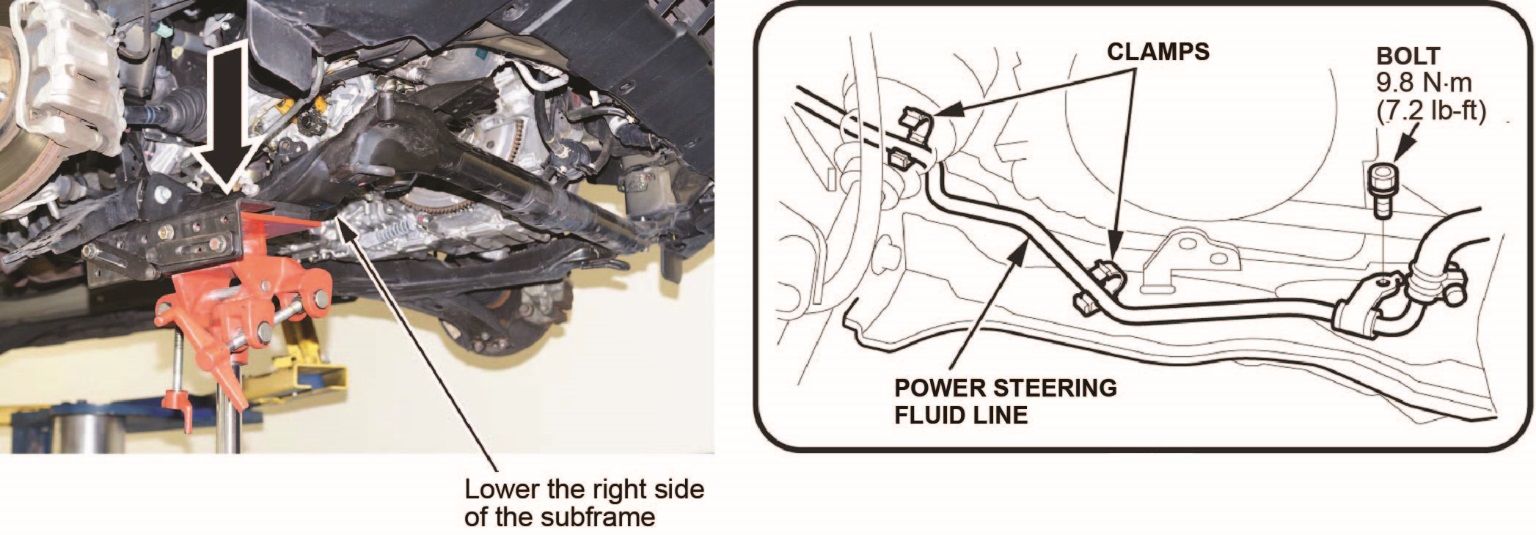

- Disconnect the power steering fluid line from the subframe by unclipping it from the clamps and removing the bolt.

- Gently lower the right side of the subframe using the transmission jack until you have enough room to remove the oil pan.

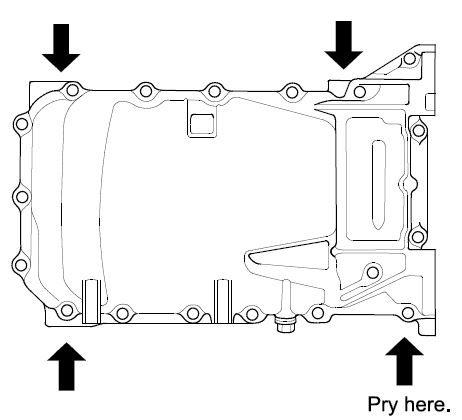

- Using the pan separator, separate the oil pan from the engine block in the indicated area, and remove the oil pan.

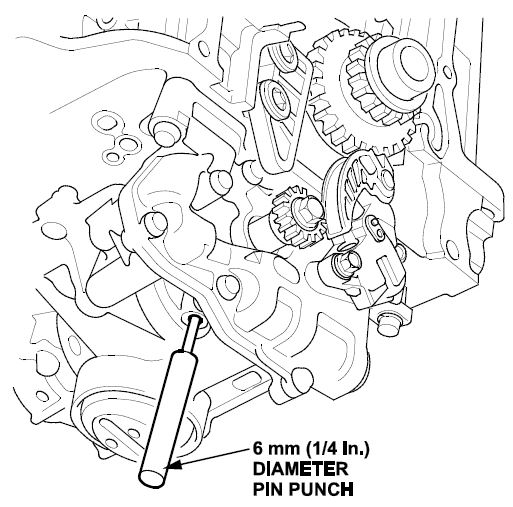

- To hold the balance shaft, insert a 6 mm (1/4in.) diameter long pin punch into the maintenance hole in the balance shaft holder and through the rear balancer shaft.

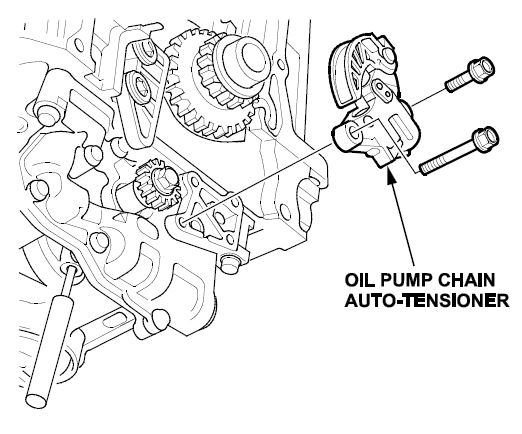

- Remove the cam chain and oil pump chain auto-tensioner.

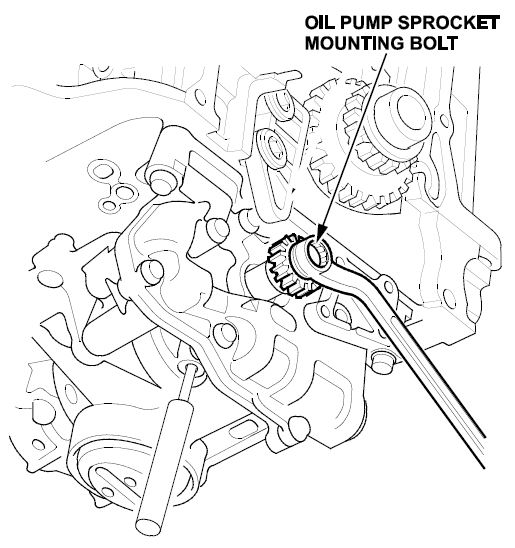

- Loosen the oil pump sprocket mounting bolt.

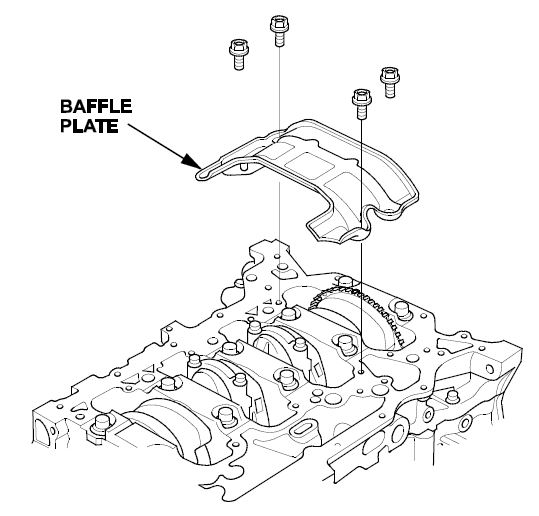

- Remove the baffle plate.

- Lower the vehicle to a comfortable working height, and place a clean shop towel around the cylinder wall to prevent debris from entering the coolant passage.

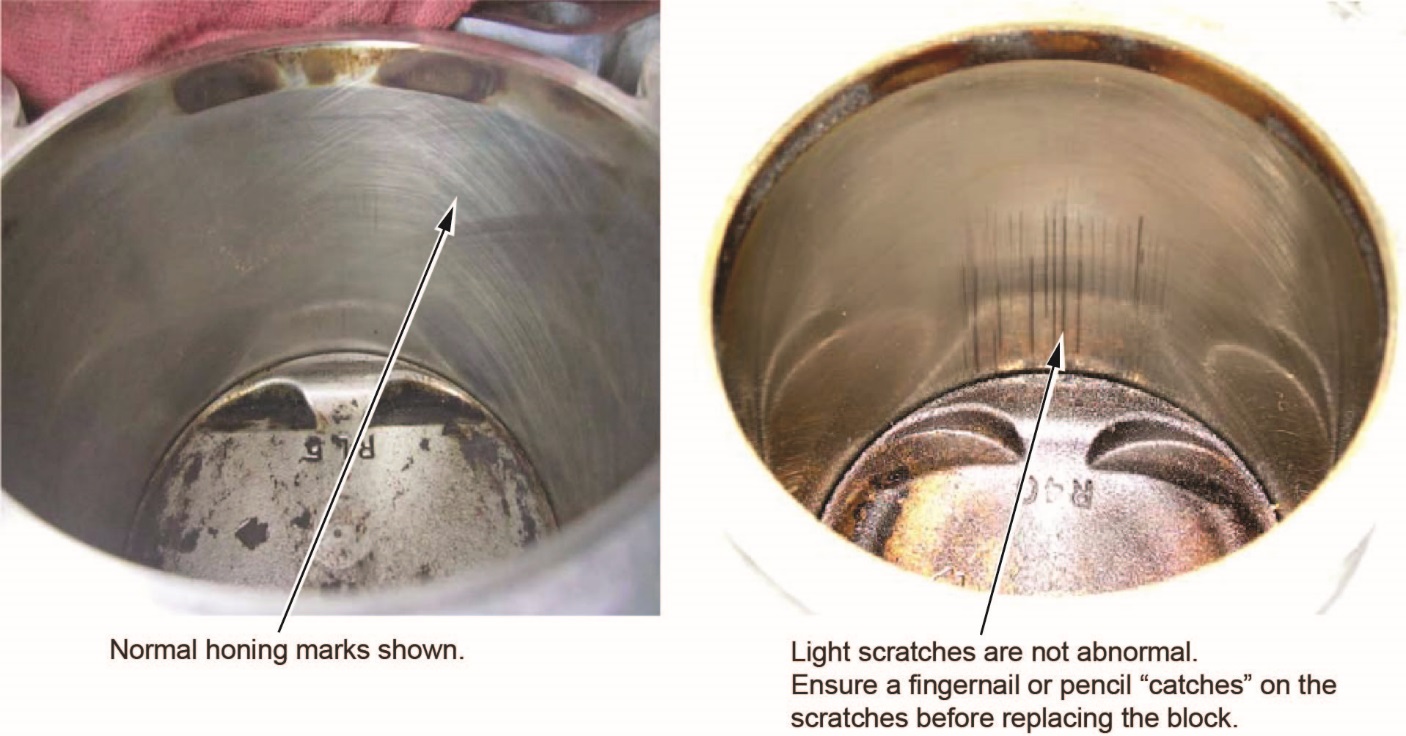

- Check the cylinder walls by rubbing your fingernail or a pencil with light pressure perpendicular to any vertical scratches that are in the cylinder bore.

- If your fingernail or pencil does not catch on the scratches, the cylinder block is OK. Go to step 33.

- If your fingernail or pencil catches on the scratches, go to step 32 to continue checking the cylinder block.

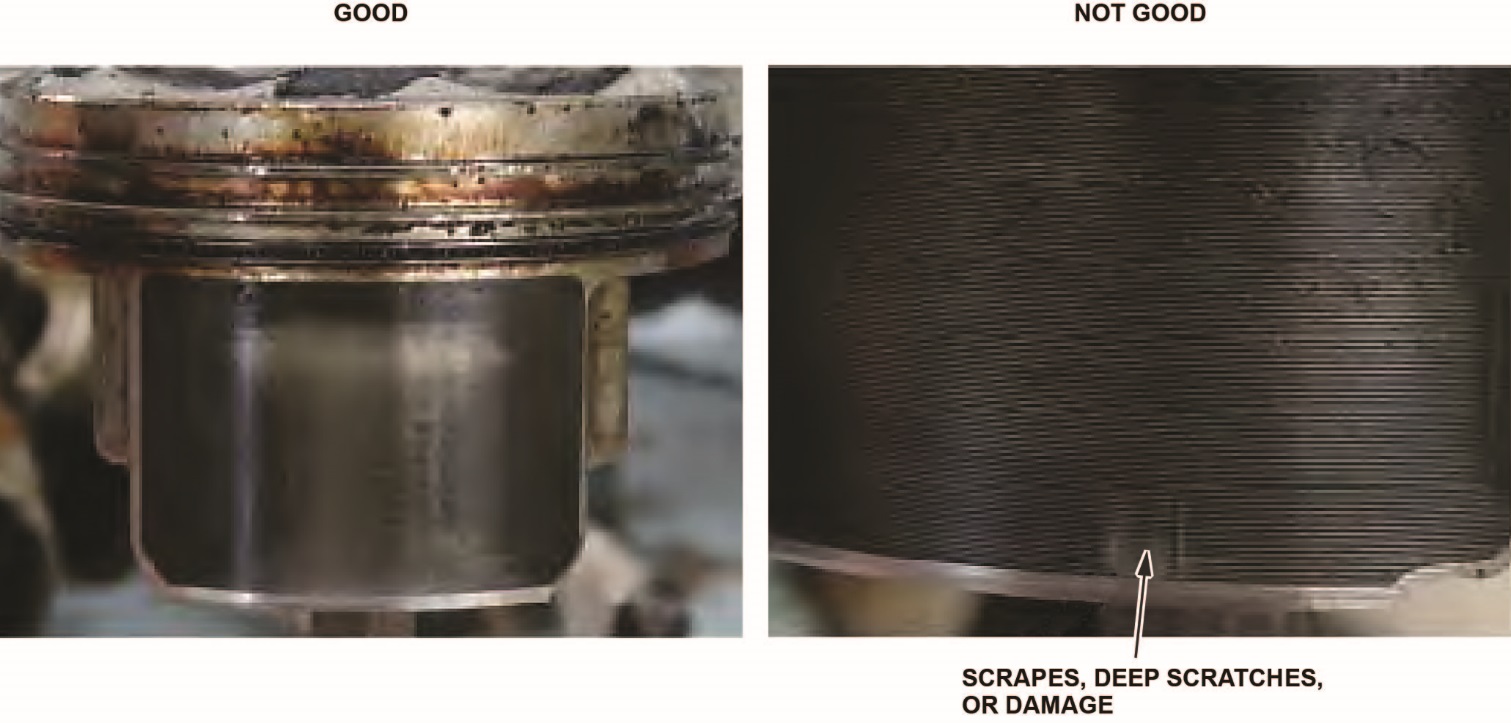

- Remove the piston from the scratched cylinder bore. Inspect the piston skirt for any scratches or damage that corresponds with the scratched cylinder bore.

- If the piston skirt has deep scratches, or is damaged, and corresponds to the position of the bore scratches, replace the engine block. This bulletin no longer applies. You must obtain DPSM authorization and refer online to Engine Removal and Installation to reinstall the engine.

- If the piston skirt has no damage, the cylinder block is OK; go to step 33.

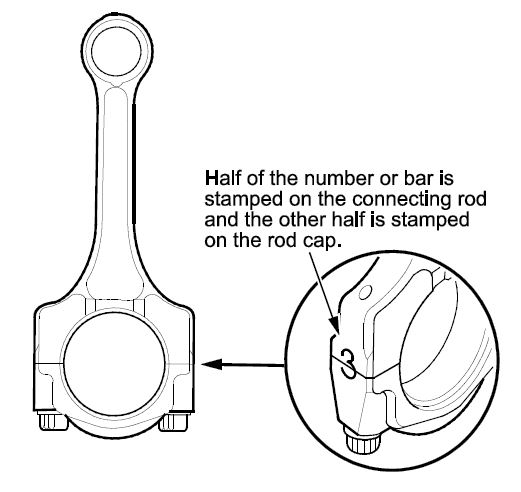

- Remove the rod caps and the bearings.

NOTE:

- Mark each rod cap and its corresponding rod with the cylinder number.

- The existing markings refer to the size of the big end of the rod, not the number of the cylinder.

- Use a wooden hammer handle to drive out each of the piston and connecting rod assemblies.

NOTE: Be careful not to damage the cylinder walls or the crankshaft when pushing out the pistons and the connecting rod assemblies.

- Visually inspect all the connecting rod bearing for signs of damage.

NOTE: If your fingernail catches on a scratch or groove in the bearing, replace it. Pictured are normal reusable rod bearings after about 35,000 miles. Some discoloration is normal and does not require replacement.

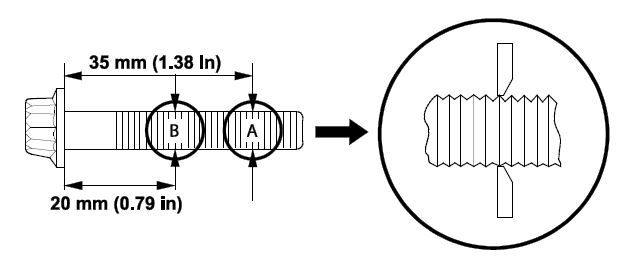

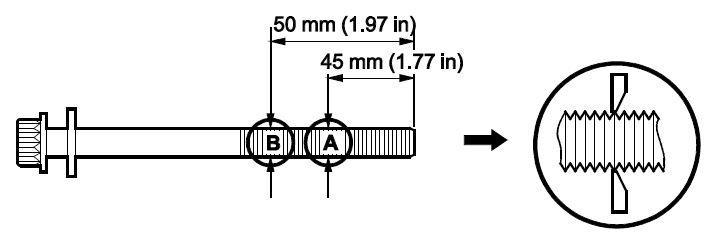

- Measure the diameter of each connecting rod bolt at points A and B.

- Calculate the difference in diameter between points A and B:

- Point A – Point B = Difference in Diameter

- Difference in Diameter Specification: 0 – 0.1 mm (0.004 in.)

- If the difference in diameter is out of specification, replace the connecting rod bolt.

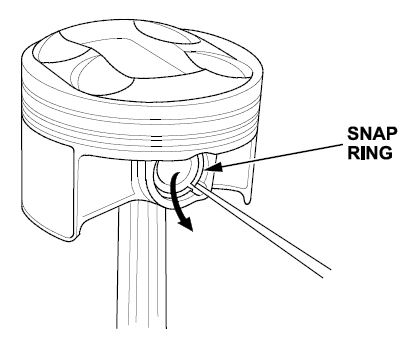

- Put on eye protection, then remove the snap rings from both sides of each piston. Start at the cutout in the piston pin Remove the snap rings carefully so they don’t go flying or get lost.

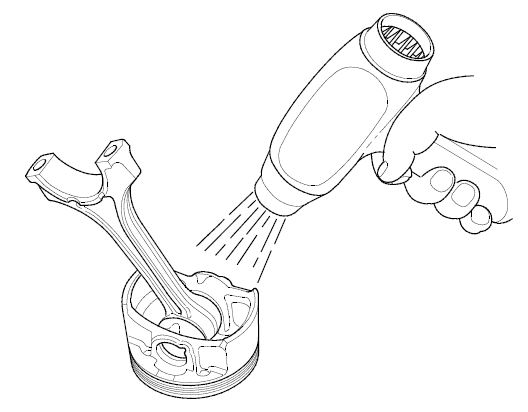

- Put on gloves, heat the piston and the ends connecting rod to about 158°F (70°C), then remove the piston pin.

NOTE: The old piston, the pin, and the snap rings won’t be reused.

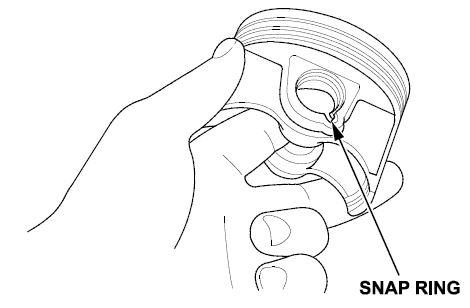

- Install a new piston pin snap ring on one side of a new piston.

- Coat the piston pin bore in the piston, the bore in the connecting rod, and the piston pin with new engine oil.

- Heat the piston to about 158°F (70°C).

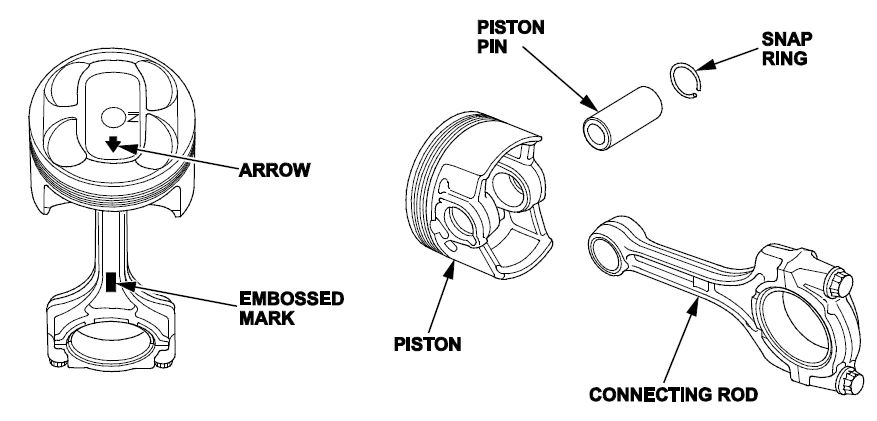

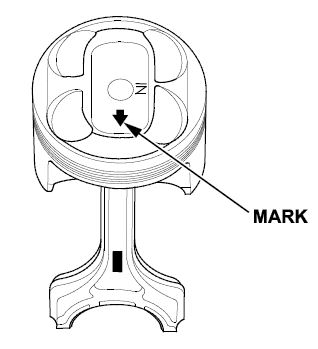

- Assemble the piston and the connecting rod with the arrow and the embossed mark on the same side. Install the piston pin.

NOTE: When the piston and the rod end are heated properly, the piston pin should slide into position relatively easily. You will damage the piston if you try to use a hammer or a press to force the piston pin in.

- Install the remaining snap ring.

- Turn the snap ring in the ring grooves until the end gaps are positioned at the bottom of the piston.

- Repeat steps 39 through 46 for the remaining pistons.

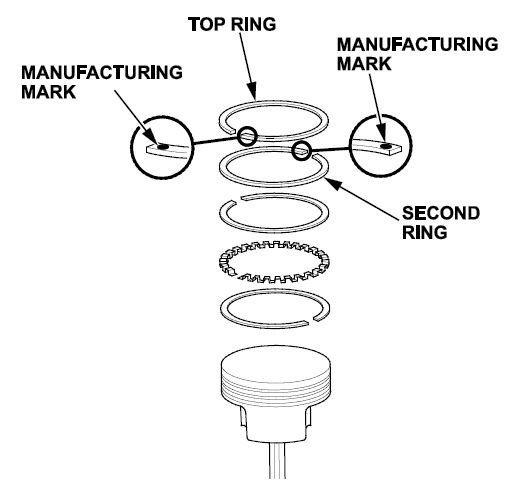

- Using a piston ring expander, install the spacer and two oil rings. Then install the second ring and top ring with the manufacturing marks facing up. The second ring has a “2” followed by a letter or letters. The top ring has a “1” followed by a letter or letters.

NOTE: The new rings may not have the same manufacturing marks as the originals.

- Rotate the rings in their grooves to make sure they do not bind.

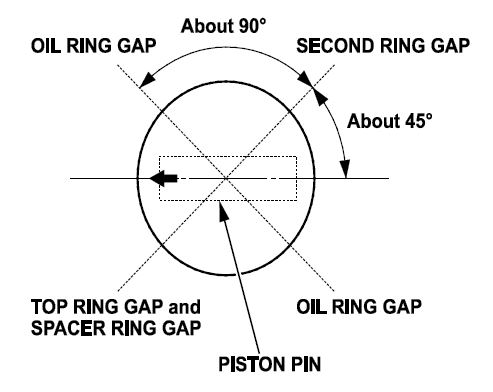

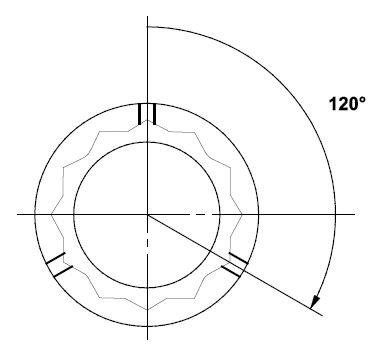

- Position the ring end gaps as shown.

- Rotate the crankshaft so that cylinders 1 and 4 are at bottom dead center (BDC).

- Remove the connecting rod cap to piston 1, and check that the bearing is securely in place.

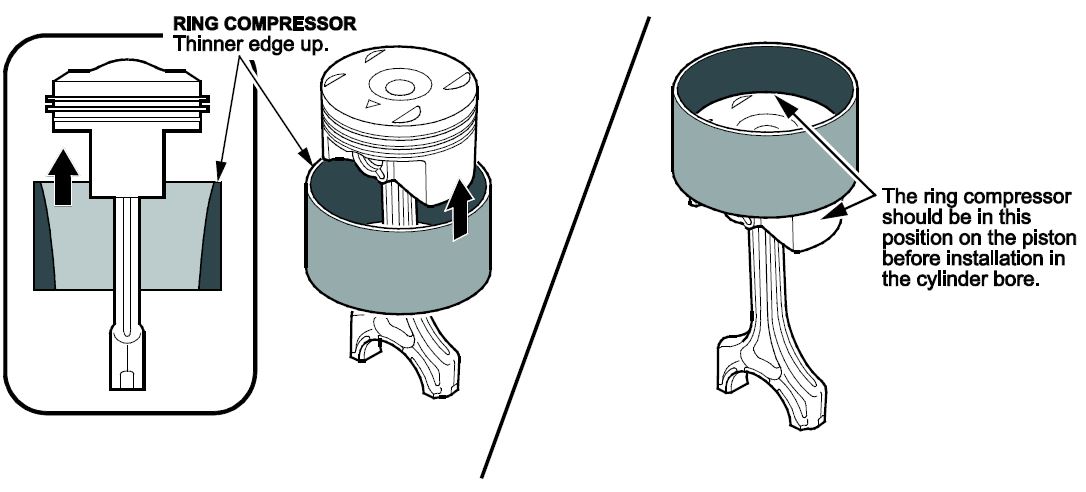

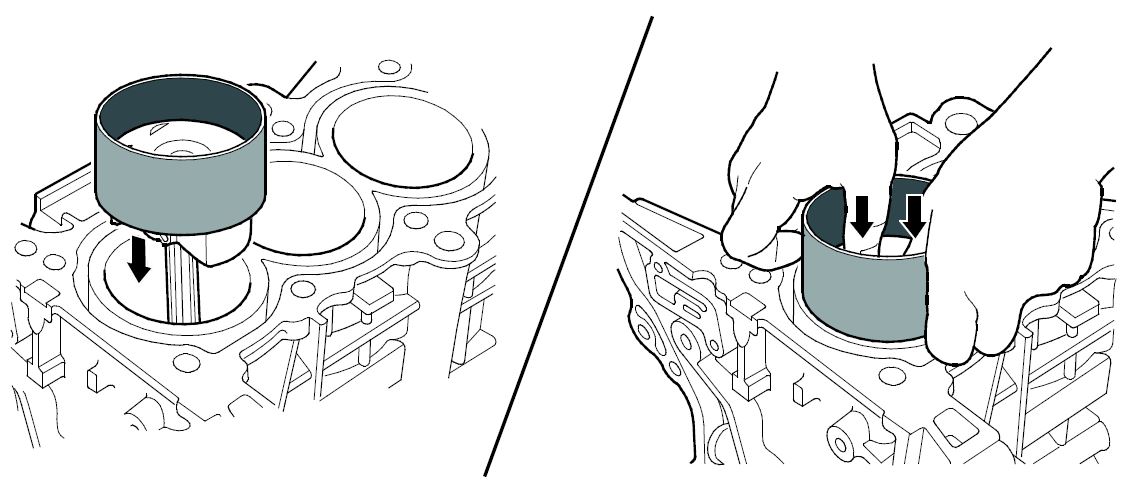

- Apply new engine oil to the piston, the inside of the ring compressor, the cylinder bore, and the rod bearings

- Position the mark to face the cam chain end of the engine block.

- Set the piston in the ring compressor, and position the piston in the cylinder noting the rod/cap marks that you made in step 34

- Set the ring compressor on the piston bore, then push the piston in with your hands.

- Stop after the ring compressor pops free, and check the connecting rod-to-rod journal alignment before pushing the piston into place.

- Apply new engine oil to the bolt threads, then install the connecting rod cap with the bearing. Torque the bolts to 41 N·m (30 lb-ft).

- Tighten the connecting rod bolts an additional 120°.

NOTE: If you tighten a rod bolt beyond the specified angle, remove it and repeat steps 58 and 59. Do not loosen the bolt back to the specified angle.

- Repeat steps 47 through 58 for piston number 4.

- Rotate the crankshaft so that cylinders 2 and 3 are at bottom dead center (BDC).

- Repeat steps 47 through 58 for piston number 2 and 3.

- Rotate the crankshaft several times after all connecting rods have been installed to ensure that nothing is binding.

- Install the baffle plate, and torque the bolts to 12 N·m (8.7 lb-ft).

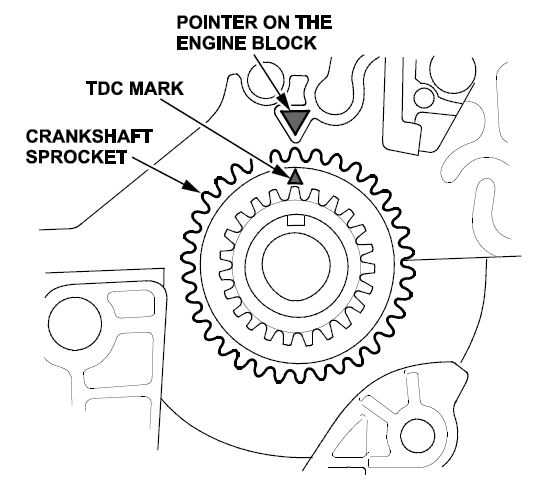

- Set the crankshaft to top dead center (TDC). Align the TDC mark (A) on the crankshaft sprocket with the pointer (B) on the engine block.

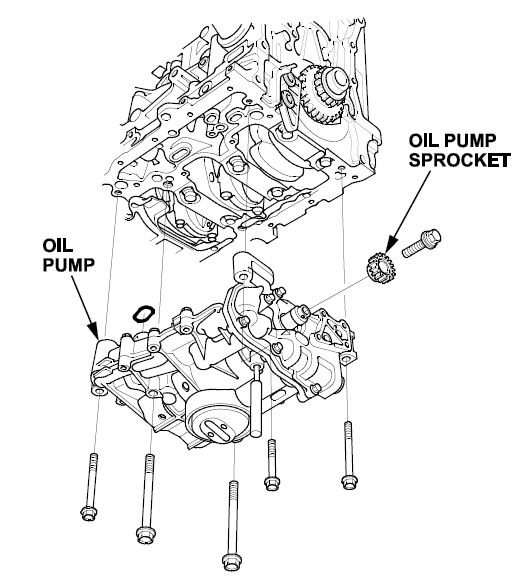

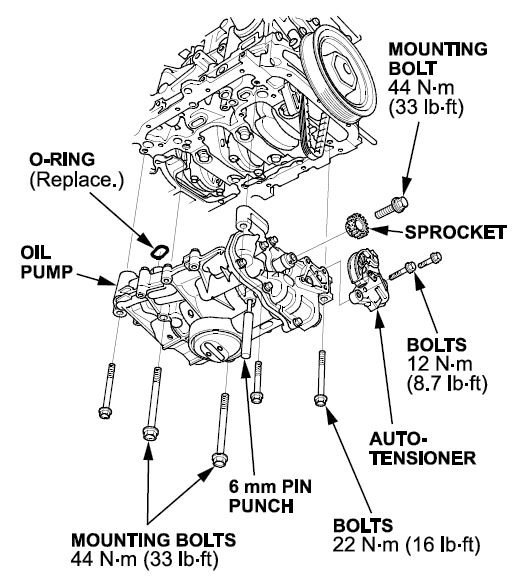

- Apply new engine oil to the threads of the oil pump mounting bolts (B) and the oil pump sprocket mounting bolt (C), then loosely install the oil pump (D) with a new O-ring (E)

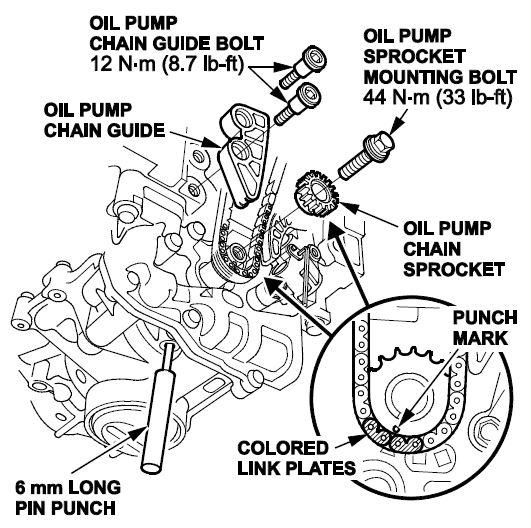

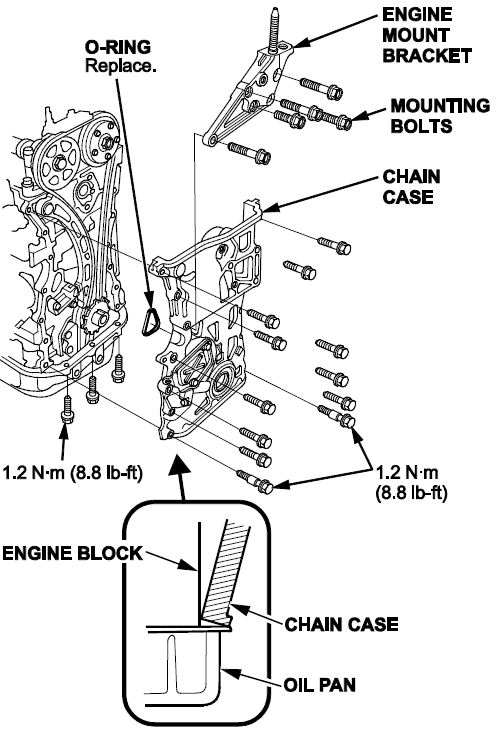

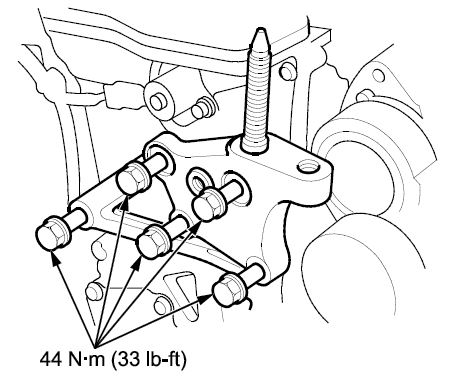

- Torque the oil pump mounting bolts and the oil pump sprocket mounting bolt according to figure shown.

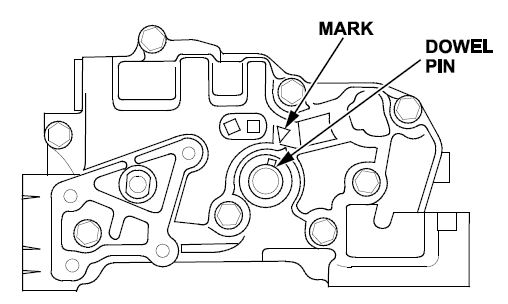

- Align the dowel pin (A) on the rear balancer shaft with the mark (B) on the oil pump.

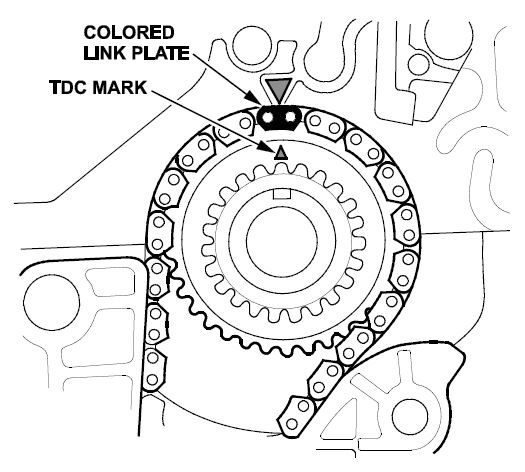

- Install the oil pump chain on the crankshaft sprocket with the colored link plate (A) aligned with the TDC mark (B) on the crankshaft sprocket.

- Set the oil pump sprocket on the oil pump chain with the punch mark aligned with the center of the colored link plates, then install the oil pump chain sprocket to the oil pump.

- Apply new engine oil to the threads of the oil pump sprocket mounting bolt, then install it and torque it to 44 N·m (33 lb-ft).

- Install the oil pump chain auto-tensioner, and torque the bolts to 12 N·m (8.7 lb-ft).

- Remove the 6 mm (1/4 in.) diameter long pin punch.

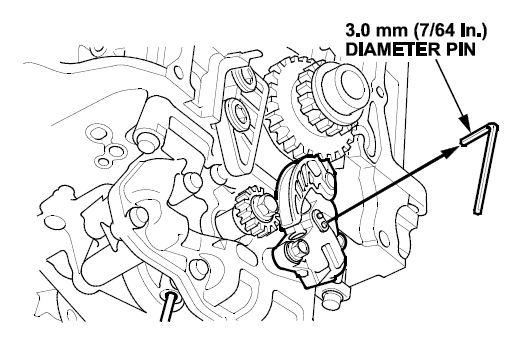

- Remove the 3.0 mm pin from the oil pump chain auto-tensioner.

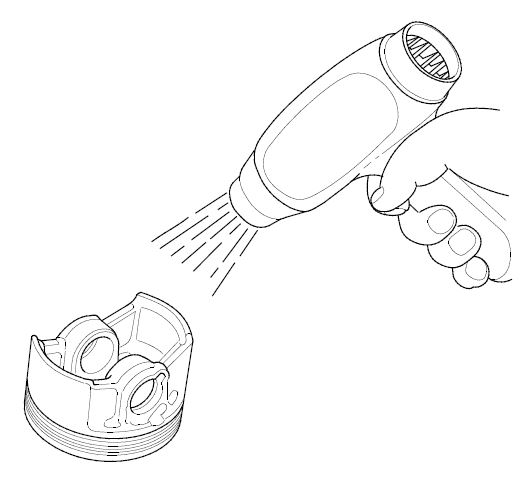

- Remove all of the old liquid gasket from the oil pan mating surfaces, the bolts, and the bolt holes.

- Clean and dry the oil pan mating surfaces.

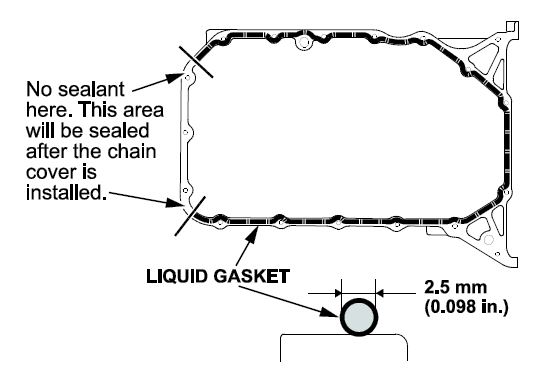

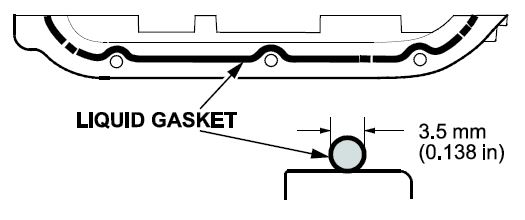

- Apply liquid gasket, P/N 08718-0004, 08718-0003, or 08718-0009, to the engine block mating surface of the oil pan and to the inside edge of the threaded bolt holes. Install the component within 5 minutes of applying the liquid gasket.

NOTE:

- Apply a 2.5 mm (0.098 in) diameter bead of liquid gasket along the broken line.

- If more than 5 minutes have passed after applying the liquid gasket, remove the old liquid gasket and residue, then reapply new liquid gasket.

- Do not apply any sealant where the cam chain case is installed because the sealant will dry before you can reinstall the case.

- Install the oil pan to the engine block.

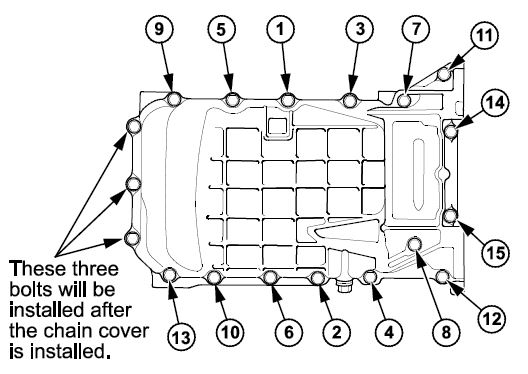

- Tighten the bolts in three steps. In the final step, torque all bolts, in sequence, to 12 N·m (9 lb-ft).

NOTE:

- Install the three bolts on the end after installing the cam chain cover.

- Wait at least 30 minutes after installing the cam chain case before filling the engine with oil.

- Do not run the engine for at least 3 hours after installing the oil pan.

- Install a new oil filter.

- Reinstall the clutch case cover and torque the bolts to 12 N·m (8.7 lb-ft). Reinstall the two bolts securing the oil pan to the transmission and torque them to 64 N·m (47 lb-ft).

- Reinstall the cylinder head with a new gasket.

- Measure the diameter of each cylinder head bolt at point A and point B.

- If either diameter is less than 10.8 mm (0.417 in), replace the cylinder head bolt.

- Apply new engine oil to the threads and under the bolt heads of all cylinder head bolts.

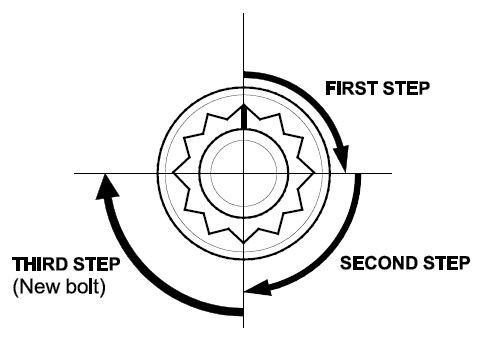

- Torque the cylinder head bolts in sequence to 39 N·m (29 lb-ft). When using a preset click-type torque wrench, be sure to tighten slowly and do not overtighten. If a bolt makes any noise while you are torquing it, loosen the bolt and retighten it from the first step.

- After torquing, tighten all cylinder head bolts in two steps (90° per step) using the sequence shown above. If you are using a new cylinder head bolt, tighten the bolt an extra 90°.

NOTE: Remove the cylinder head bolt if you tightened it beyond the specified angle, and go back to the second bullet to remeasure the bolt. Do not loosen it back to the specified angle.

- Reinstall the rocker arm assembly and the camshafts.

- Reinstall the cam chain.

- Apply liquid gasket to the oil pan where it meets the cam chain case and to the inside edge of the threaded bolt holes. Install the cam chain case within 5 minutes of applying the liquid gasket.

- Install the cam chain cover.

- Reinstall the engine mount bracket and torque the bolts to 44 N·m (33 lb-ft).

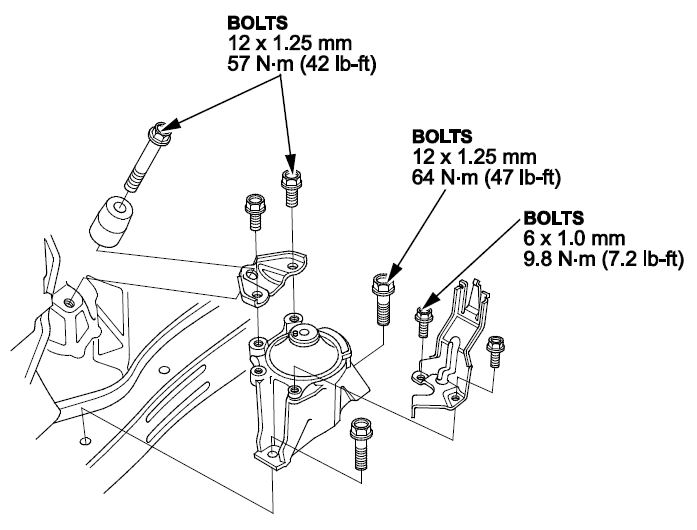

- Reinstall the engine side mount using new bolts and nut.

- Remove the engine hanger, and reinstall the subframe.

- Reconnect the power steering feed line to the subframe. Torque the bolt to 8 N·m (7.2 lb-ft).

- Adjust the valve clearance. Refer to the service manual for Valve Clearance Adjustment.

Valve Clearance

Intake: 0.21–0.25 mm (0.0083–0.0098 in)

Exhaust: 0.25–0.29 mm (0.0098–0.0114 in)

Specified Torque (Intake & Exhaust)

7 x 0.75 mm: 14 N·m (1.4 kgf·m, 10 lbf·ft)

Apply new engine oil to the nut threads.

- Reinstall the cylinder head cover.

- Reinstall the connecting pipe.

- Install the intake manifold using new gaskets.

- Reinstall the radiator hoses and the heater hoses 93. Reinstall the EVAP canister purge valve bracket.

- Reconnect the engine mount control solenoid connector, and the ground cables.

- Reconnect the fuel feed hose, and reinstall the quick-connect fitting cover.

- Reconnect the EVAP canister hose and the brake booster vacuum hose.

- Install new gasket from TWC to A-pipe.

- stall new gasket from TWC to A-pipe.

- Reinstall drive belt.

- Fill the engine with coolant, using recovered coolant. Add new as needed.

- Fill the engine with oil.

- Do the battery terminal reconnection procedure.

- Crank the engine for about 5 seconds to prime the engine with oil pressure before plugging in the ignition coils.

- Reconnect the four ignition coil connectors 104. Do the idle learn procedure.

END.

ORDERING PISTONS

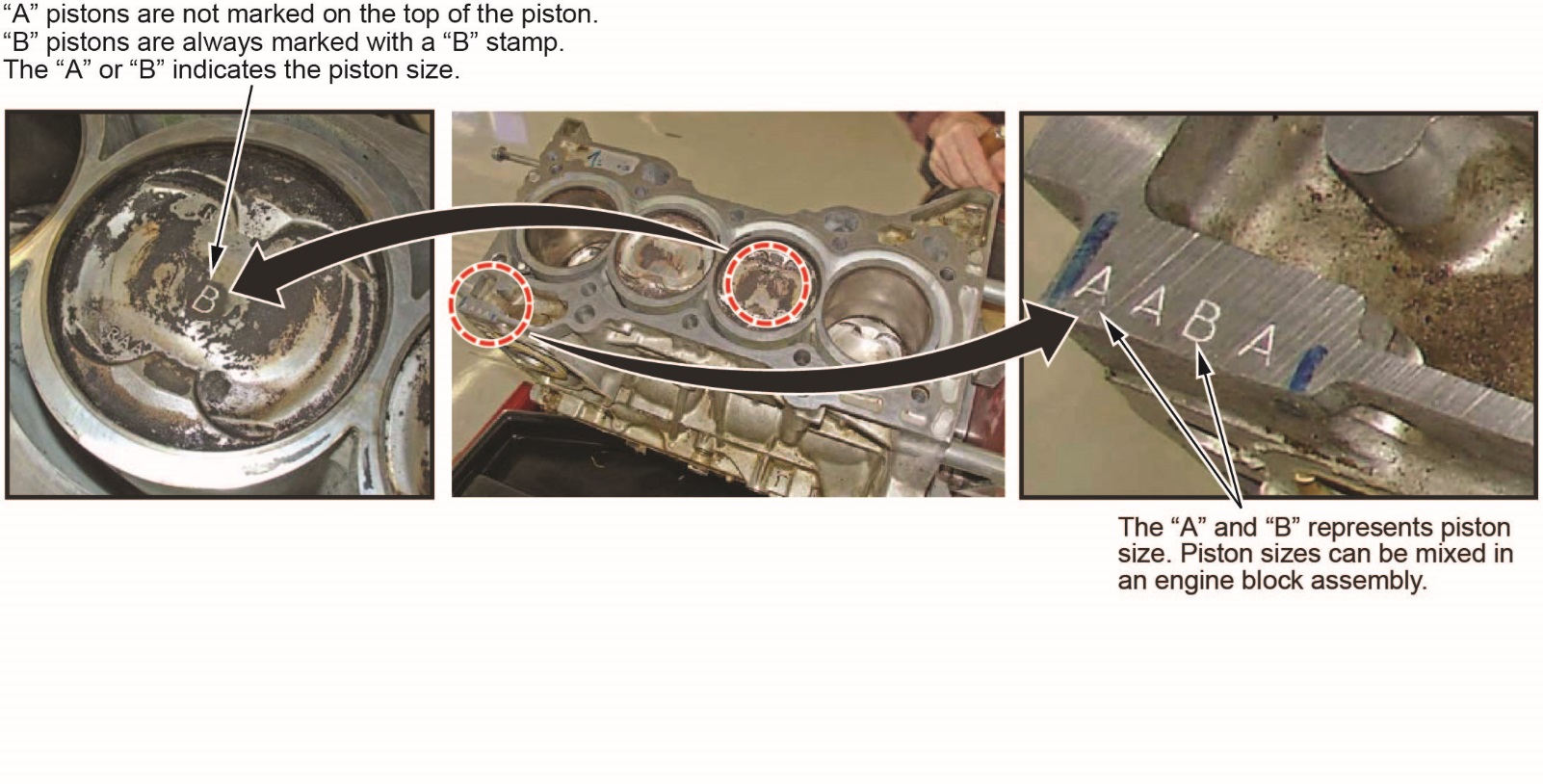

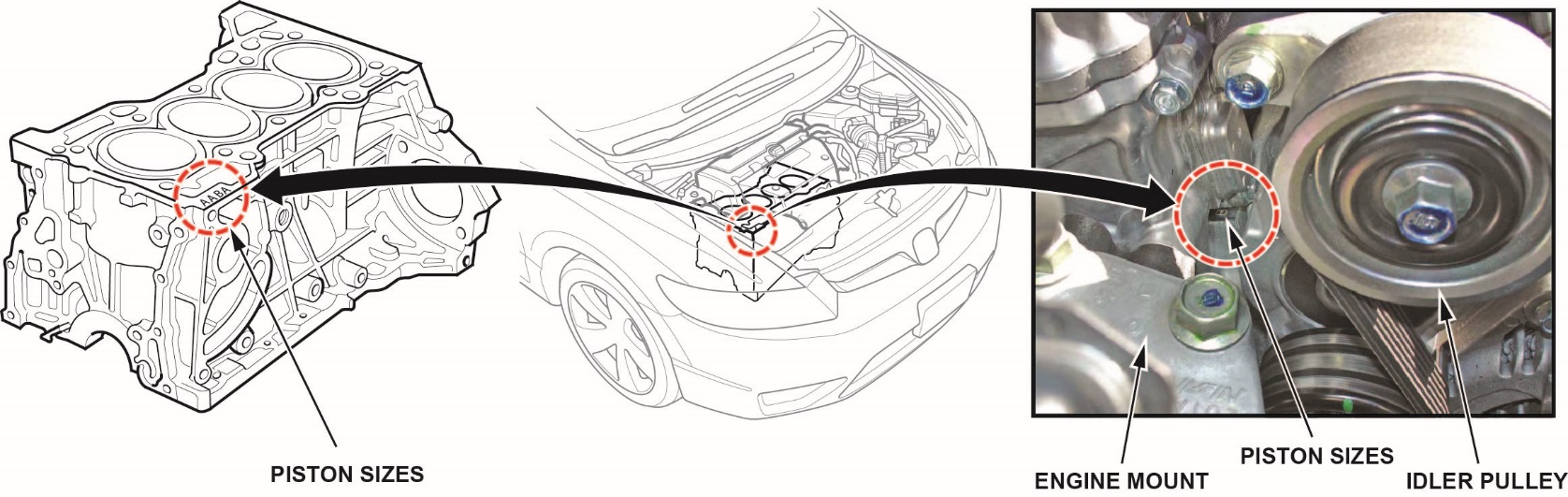

Every engine has some combination of A- and B-sized pistons. You can determine the sizes and their locations in the block by inspecting the markings on the timing chain end of the engine block or by looking at the pistons. If you look at the piston, the pistons have identifiers; “A” pistons are unmarked; “B” pistons are marked with a “B”. Make sure you order the appropriate number of each piston size before starting work.

2 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

| HONDA | CR-V | 2010-2011 |

1 Associated Document

Service Bulletin Document

A12-089

March 31, 2017

06118 Version 7

https://www.nhtsa.gov/recalls?nhtsaId=10108323

SB-10108323-9340.pdf 3216.061KB

Loading...

Loading...

- Mobil 1 Extended Performance full-synthetic motor oil 0W-20 helps protect critical engine parts for up to 20,000 miles between oil changes,* controlling oxidation to prevent oil breakdown and maintaining excellent viscosity

- Utilizes Mobil 1’s Triple Action+ Formula to combine outstanding engine performance, protection, and cleanliness with the added benefit of power

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Helps extend engine life by working to prevent damaging deposits and sludge buildup

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -40 degrees F)

- 3X Stronger than the leading full synthetic*

- 10X Better high stress performance**

- 20,000 miles between oil changes***

- Approved and Licensed Specifications: Exceeds API SP/SN PLUS/SN/SM |ILSAC GF-6 | GM dexos1 Gen 3 | Meets engine test requirements of Chrysler MS 6395 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Viscosity breakdown as measured in Kurt Orbahn test on 5W-30 grade |**As measured in Seq IX test under high load/torque conditions vs. API SP test limits | ***Or one year, whichever comes first

- 6X better wear protection on critical engine parts than industry standards**

- 1.3X better sludge protection than industry standards*

- 3X Stronger against viscosity breakdown than leading full synthetic^

- Protection for 10,000 miles between oil changes

- Meets or exceeds the following specifications: API SP/SN PLUS/SN | ILSAC GF-6 | GM dexos1 Gen 3 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A1 |

- Full synthetic 0W-20 motor oil that is made with natural gas and designed to maximize engine protection

- Backed by a 15,000-mile protection guarantee* to protect your pursuit of every mile

- Provides better fuel economy (based on the latest industry standards)

- Keeps pistons cleaner than the toughest industry standard (based on Sequence IIIH results)

- Provides unsurpassed wear protection (based on Sequence IVA wear test using SAE 5W-30)

- Mobil 1 High Mileage full-synthetic motor oil 0W-20 is designed for engines with over 75,000 miles to go up to 10,000 miles between oil changes.*

- Utilizes Mobil 1’s signature Triple Action Formula to deliver outstanding engine performance, protection, and cleanliness

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -30 degrees F)

- Mobil 1 is specially formulated to help remove sludge and lower engine temperatures

- Advanced protection against the four main causes of engine breakdown: wear friction heat and deposits

- Full synthetic 0W-20 formula offers 24X stronger protection against engine-killing contaminants than the leading full synthetic motor oil

- 40% better wear protection vs. industry standards as tested in the Sequence IVB engine test

- 25% better deposit protection with superior engine cleaning detergents as tested in the GMOD engine test

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN, GM dexos 1 Gen 3

- Our most advanced full synthetic 0W-20 engine oil, designed for unbeatable engine protection*

- Pennzoil Ultra Platinum comes with a 20-year, 750,000 mile warranty** to protect your engine and give you peace of mind to drive every mile as hard as you can

- Made with natural gas

- Outstanding performance in extreme temperatures

- Designed for high-performance engines, it helps protect engines from loss of power

- The information below is per-pack only

- Mobil 1 Extended Performance High Mileage full-synthetic motor oil 0W-20 is designed for engines with over 75,000 miles to go up to 20,000 miles between oil changes.*

- Utilizes Mobil 1’s Triple Action+ Formula to combine outstanding engine performance, protection, and cleanliness with the added benefit of power

- Meets ILSAC GF-6 standards to help provide low-speed pre-ignition (LSPI) and timing chain wear protection while keeping your engine clean and helping to improve your fuel economy

- Provides excellent internal engine heat protection (up to 500 degrees F) and low temperature protection (to -40 degrees F)

- Phosphorus Replacement Technology to help extend the life of the emission system

- Reduces leaks, oil burnoff and power robbing deposits

- 15,000 miles between oil changes*

- Meets or exceeds the following specifications: API SP/SN PLUS/SN/SM | ILSAC GF-6 | Meets engine test requirements of Chrysler MS 6395 | Meets Ford WSS-M2C947-B1 | Meets Ford WSS-M2C962-A2

- Or one year, whichever comes first

- Full synthetic formula is engineered with Enhanced MaxLife Technology to prevent engine breakdown in vehicles with over 75,000 miles

- Formulated with seal conditioners to prevent and treat oil leaks, Valvoline Full Synthetic High Mileage minimizes oil consumption and maximizes engine life

- 50% better wear protection than the industry standard and 25% extra defense against deposits, sludge, corrosion and rust

- Meets or exceeds all requirements of ILSAC GF-6A, API SP, API SN with SN Plus, API SN

- American made and formulated, from the Original Motor Oil brand trusted for more than 150 years

SEOCONTENT-START

(g)HONDA Service Bulletin 12-089

March 31, 2017 06118 Version 7

Warranty Extension: Sticking Rings Resulting in High Engine Oil

Consumption

Supersedes 12-089, Sticking Rings Resulting in Unusually High Engine Oil Consumption, dated April 20, 2016;

see Revision Summary

AFFECTED VEHICLES

Year Model Trim VIN Range

2010-11 CR-V ALL Check the iN VIN status eligibility

REVISION SUMMARY

Under REQUIRED MATERIALS, the oil was changed to Full Synthetic Engine Oil, P/N 08798-9063.

BACKGROUND

American Honda is extending the warranty coverage on the Piston Rings and Pistons for 2010-11 CR-V 2WD and 4WD

to 8 years from the original date of purchase or 125,000 miles, whichever comes first.

The warranty extension does not apply to any vehicle that has ever been declared a total loss or sold for salvage by a

financial institution or insurer, or has a branded, or similar tittle under any state’s law. To check for vehicle eligibility,

you must do a VIN status inquiry.

CUSTOMER NOTIFICATION

Owners of affected vehicles will receive a notification of this warranty extension.

Do an iN VIN status inquiry to make sure the vehicle is shown as eligible.

SYMPTOM

The engine oil level is low on the dipstick, and the oil warning light may come on in rare high oil consumption situations.

POSSIBLE CAUSES

Under certain specific circumstances the engine may create deposits on the oil control rings, which may lead to

increased oil consumption when all of the following conditions occur simultaneously on a regular and prolonged basis:

• The engine is cold (not warmed up to operating temperature)

• Hard acceleration while the engine is cold

• The fuel used has an unusually high concentration of particles – Honda recommends using Top Tier gas that

contains detergents to prevent deposits. For more information about Top Tier gas, go to www.toptiergas.com.

All these conditions happening at the same time is rare, but if they do, deposits may form over years of driving. If the oil

control rings begin to stick because of the deposits, the customer may subsequently complain about excessive oil

consumption.

CUSTOMER INFORMATION: The information in this bulletin is intended for use only by skilled technicians who have the proper tools, equipment,

and training to correctly and safely maintain your vehicle. These procedures should not be attempted by “do-it-yourselfers,” and you should not

assume this bulletin applies to your vehicle, or that your vehicle has the condition described. To determine whether this information applies, contact

an authorized Honda automobile dealer.

© 2017 American Honda Motor Co., Inc. – All Rights Reserved Page 1 of 31

CORRECTIVE ACTION

Do the procedure under DIAGNOSIS and based on your results, replace all of the engine pistons and piston rings if

necessary.

Service Advisor: Talk to the customer about the many factors contributing to oil consumption. Remind him or her that

with less frequent service intervals for modern engines, it’s not uncommon to add oil between services. Therefore, it’s a

good idea to check the engine oil regularly (as recommended in the owner’s manual) and add oil as necessary.

PARTS INFORMATION

Part Name Part Number Quantity

BOLT, CONNECTING ROD (Up to 8 as required after 13204-RBB-004 8

measurements)

BOLT, WASHER, 11×176 (Up to 10 as required after 90005-RNA-A01 10

measurements)

BOLT, FLANGE 12X40 (Side engine mount) 95701-12040-08 2

Drain plug washer 94109-14000 1

GASKET, Cylinder Head 12251-R40-A01 1

GASKET,SET 12030-R44-A00 1

GASKET, Exhaust Flexible ( Catalytic to A pipe) 18229-SWA-305 1

HondaBond HT ( 1 tube repairs 5 vehicles) 08718-0004 1

Honda Coolant Type 2 ( 1 gallon will be used to top off 2 OL999-9011 1

vehicles)

Honda Motor Oil, Full Synthetic 0W-20 ( 6 quarts of oil to be 08798-9063 6

used)

Nut, Flange (Side engine mount) 90213-SSA-003 1

Oil Filter 15400-PLM-A02 1

O-Ring ( At oil pump) 91301-R40-A01 1

O-Ring, Chain Case 91302-PNA-004 1

Oil Seal, Control Valve ( O-ring at VTC Valve assembly) 15832-PNA-023 1

Packing A, Intake Manifold 17115-R40-A01 4

Piston SET A (STD) (Dealer must determine how many to 1301 0-R40-A00 4

order)

Piston SET B (STD) (Dealer must determine how many to 13020-R40-A00 4

order)

Ring Set (STD) 13011-R44-A01 4

Page 2 of 31

TOOL INFORMATION

Part Name Part Number Quantity

Camshaft Lock Pin Set 07 AAB-RWCA 120 1

Crank Pulley Holder 07 AAB-RJAA 100 1

Engine Hanger AART1256 1

Handle 6-25-660L 07JAB-001020B 1

Gasket Remover/Pan Separator LIL50190 1

Piston Ring Expander Snap-On PRS8 or 1

equivalent

Piston Ring Compressor SCP1287 or equivalent 1

1/2 in. Drive Torque Angle Gauge BLMBLDAG001 or TA360 1

NOTE: These Items can be purchased through the Honda Tool & Equipment Program 888-424-6857.

WARRANTY CLAIM INFORMATION

Operation Description Flat Rate Time Failed Part Number

Number

1111 BF Replacing all pistons and 11.8 hrs (includes 0.4hr 13010-RLS-A 10

piston rings for alignment)

Defect Code: SX100

Symptom Code: JP000

Skill Level: Repair Technician

DIAGNOSIS

1. Do an engine oil consumption test. Refer to the Job Aid Engine Oil Consumption Test.

2. Review the results of the engine oil consumption test.

• Based on the test results, if the engine is consuming an unusually high amount of oil, contact your DPSM for

approval, then go to REPAIR PROCEDURE.

• Based on the test results, if the engine is consuming a normal amount of engine oil, the vehicle is OK. Explain to the

customer that the vehicle is OK, and that the consumption of oil is within a normal range.

NOTE: Remind the customer to regularly check the engine oil level every time they fill the fuel tank. Modern engines

require less frequent oil changes, which may impact the amount of oil used between oil changes.

REPAIR PROCEDURE

This procedure is an outline form that you can also use as a checklist for the repair. For details on the procedures

noted, refer to the appropriate service manual, or view them on line.

• Engine Oil Replacement

• Battery Terminal Disconnection and Reconnection

• Fuel Pressure Relieving

• Coolant Replacement

• Drive Belt Removal/Installation

• Intake Manifold Removal and Installation

• Warm Up TWC Removal/Installation

Note: Disconnect TWC at the A-pipe at TWC.

Page 3 of 31

• Fuel Line/Quick-Connect Fitting Removal

• Cylinder Head Removal

• Cam Chain Removal

• Rocker Arm Assembly Removal

• Valve Adjustment

• Oil Pan Installation

• ECM Idle Learn Procedure

NOTE:

• Before starting work, make sure to order the correct number of “A” and “B” pistons. Refer to ORDERING

PISTONS on page 31 of this bulletin.

• Use fender covers to avoid damaging painted surfaces.

• To avoid damaging the wires and terminals, unplug the wiring connectors carefully while holding the connector

portion.

• To avoid damaging the cylinder head, wait until the engine coolant temperature drops below 100°F (38°C) before

loosening the cylinder head bolts. If needed, connect the HDS to the DLC, and monitor ECT SENSOR 1.

• Mark all wiring and hoses to avoid misconnection. Also, be sure that they do not contact any other wiring or

hoses, or interfere with any other parts.

1. Make sure that Service Bulletin 11-049, Product Update: Software Update to Improve Fuel Injector and VTC Timing

is complete by checking the iN VIN status.

NOTE: If you do not confirm software update has been completed, your warranty claim could be debited.

2. Put the vehicle on a lift.

3. Relieve the fuel pressure.

4. Do the battery terminal disconnection procedure.

5. Drain the engine oil

6. Drain the engine coolant.

NOTE: Use a clean container to recover coolant for re-use.

7. Remove the drive belt.

8. Remove the intake manifold. Remove the intake manifold bracket lower bolt.

NOTE: It is not necessary to remove the two nuts or the bracket from the intake manifold.

9. Unbolt TWC at the A-Pipe, leaving the TWC mounted to the cylinder head assembly.

Page 4 of 31

10. Disconnect the brake booster vacuum and EVAP canister hoses.

EVAP CANISTER HOSE

11. Remove the quick-connect fitting cover, then disconnect the fuel feed hose.

QUICK-CONNECT

FITTING COVER

FUEL FEED HOSE

12. Disconnect the four fuel injector connectors, the control solenoid valve connectors, and disconnect the ground

cables.

FUEL INJECTOR

CONNECTORS

GROUND

CABLES

Page 5 of 31

13. Remove the four bolts securing the EVAP canister purge valve bracket.

14. Disconnect the radiator hoses and the heater hoses. Disconnect the ATF warmer bypass hose (if equipped)

NOTE: The second radiator hose is connected to the thermostat and is not shown.

____/~RADIATOR

HOSE

HEATER

HOSES

Page 6 of 31

15. Remove the two bolts securing the connecting hose. Disconnect the water bypass hose.

CONNECTING PIPE

CONNECTING PIPE

MOUNTING BOLTS

16. Support the engine with a floor jack, then remove the right side engine mount.

17. Remove the front cam chain cover and the cam chain.

CAM CHAIN CASE

I

Page 7 of 31

18. Use zip ties to hold the four intake rocker assemblies together to ease re-installation.

19. To prevent damage to the camshafts, loosen the bolts, in sequence, two turns at a time. Remove the camshaft

holder bolts, Remove the rocker arm assembly and both cam shafts.

NOTE: Bolt #1 is not on all engines.

@ @ @ @) ®

(])@@@@®CD@@®@®

Page 8 of 31

20. To prevent warpage, loosen the bolts in sequence 1/3 turn at a time; repeat the sequence until all the bolts are

loosened, Remove the cylinder head bolts.

21. Remove the cylinder head with the catalytic converter attached.

NOTE: Be careful not to lose the lost motion springs.

Page 9 of 31

22. Raise the vehicle on the lift. Attach the engine hanger.

• Attach the engine mount bracket to the engine block with two 10 mm spacers and two (10 mm diameter) bolts

that are about 40 mm and 55 mm long.

NOTE: You can find spacers in the engine hanger kit.

ENGINE MOUNT

BRACKET~

BOLTS

• Assemble the engine hanger.

SPACERS

• Loop the wire around the engine mount bracket and attach the looped ends to the hook.

• Raise the engine with a floor jack just enough to relieve the engine weight from the lower engine bracket.

Tighten the hook so that when you lower the floor jack, the engine is suspended in place.

Page 10 of 31

23. Raise the vehicle on the lift so that you can move the axle out of the way.

LOWERARM

• Disconnect the lower ball joint from the lower control arm

• Drive the inboard joint off of the intermediate shaft using a drift punch and a hammer, then move the shaft out

of your way

24. Remove the oil pan.

• Remove the torque converter cover, then remove the two bolts securing the oil pan to the transmission.

Page 11 of 31

• Remove the lower torque rod mounting bolts.

· … 2 0~~~:

BOLTS

• Loosen the mid-stiffener mounting bolt on both slides.

~~SUBFRAME

~~ I MID-BRACKET BOLT

~ (Both sides.)

• Place a transmission jack under the right side of the subframe and remove the subframe bolts on the right

side.

Remove the three

right-side subframe bolts.

Loosen the three

left-side subframe bolts.

Page 12 of 31

• Loosen the subframe mounting bolts on the left side so that you can lower the subframe about 20 mm.

• Remove the lower torque rod bracket.

• Remove the bolts securing the oil pan.

Pry here.

• Raise the engine as high as possible using the engine hanger hook.

NOTE: The engine wobbles as it is being lifted, so make sure nothing is stressed or damaged such as the A/C

lines or pump

• Disconnect the power steering fluid line from the subframe by unclipping it from the clamps and removing the

bolt.

• Gently lower the right side of the subframe using the transmission jack until you have enough room to remove

the oil pan.

Lower the right side

of the subframe

BOLT

9.8 N-m (lj lb-ft)

,,—1.H ~

• Using the pan separator, separate the oil pan from the engine block in the indicated area, and remove the oil

pan.

Page 13 of 31

25. To hold the balance shaft, insert a 6 mm (1/4in.) diameter long pin punch into the maintenance hole in the balance

shaft holder and through the rear balancer shaft.

6 mm (1/4 in.)

DIAMETER

PIN PUNCH

26. Remove the cam chain and oil pump chain auto-tensioner.

OIL PUMP CHAIN

AUTO-TENSIONER

Page 14 of 31

27. Loosen the oil pump sprocket mounting bolt.

28. Remove the oil pump sprocket and the oil pump.

OIL PUMP SPROCKET

MOUNTING BOLT

Page 15 of 31

29. Remove the baffle plate.

30. Lower the vehicle to a comfortable working height, and place a clean shop towel around the cylinder wall to prevent

debris from entering the coolant passage.

31. Check the cylinder walls by rubbing your fingernail or a pencil with light pressure perpendicular to any vertical

scratches that are in the cylinder bore.

• If your fingernail or pencil does not catch on the scratches, the cylinder block is OK. Go to step 33.

• If your fingernail or pencil catches on the scratches, go to step 32 to continue checking the cylinder block.

Normal honing marks shown. Light scratches are not abnormal.

Ensure a fingernail or pencil “catches” on the

scratches before replacing the block.

32. Remove the piston from the scratched cylinder bore. Inspect the piston skirt for any scratches or damage that

corresponds with the scratched cylinder bore.

• If the piston skirt has deep scratches, or is damaged, and corresponds to the position of the bore scratches, replace

the engine block. This bulletin no longer applies. You must obtain DPSM authorization and refer on line to Engine

Removal and Installation to reinstall the engine.

Page 16 of 31

• If the piston skirt has no damage, the cylinder block is OK; go to step 33.

GOOD

33. Remove the rod caps and the bearings.

NOTE:

NOT GOOD

SCRAPES, DEEP SCRATCHES,

OR DAMAGE

• Mark each rod cap and its corresponding rod with the cylinder number.

• The existing markings refer to the size of the big end of the rod, not the number of the cylinder.

Half of the number or bar is

stamped on the connecting rod

and the other half is stamped

on the rod~

34. Use a wooden hammer handle to drive out each of the piston and connecting rod assemblies.

NOTE: Be careful not to damage the cylinder walls or the crankshaft when pushing out the pistons and the

connecting rod assemblies.

Page 17 of 31

35. Visually inspect all the connecting rod bearing for signs of damage.

NOTE: If your fingernail catches on a scratch or groove in the bearing, replace it. Pictured are normal reusable rod

bearings after about 35,000 miles. Some discoloration is normal and does not require replacement.

36. Measure the diameter of each connecting rod bolt at points A and B.

~ 35mm(1.~ln)’

~ 11111+11W111 …

20 mm (0.79 in)

37. Calculate the difference in diameter between points A and B:

• Point A – Point B = Difference in Diameter

• Difference in Diameter Specification: O – 0.1 mm (0.004 in.)

• If the difference in diameter is out of specification, replace the connecting rod bolt.

38. Put on eye protection, then remove the snap rings from both sides of each piston. Start at the cutout in the piston pin

bore. Remove the snap rings carefully so they don’t go flying or get lost.

SNAP

RING

39. Put on gloves, heat the piston and the ends connecting rod to about 158°F (70°C), then remove the piston pin.

Page 18 of 31

NOTE: The old piston, the pin, and the snap rings won’t be reused.

40. Install a new piston pin snap ring on one side of a new piston.

41. Coat the piston pin bore in the piston, the bore in the connecting rod, and the piston pin with new engine oil.

42. Heat the piston to about 158°F (70°C).

Page 19 of 31

43. Assemble the piston and the connecting rod with the arrow and the embossed mark on the same side. Install the

piston pin.

NOTE: When the piston and the rod end are heated properly, the piston pin should slide into position

relatively easily. You will damage the piston if you try to use a hammer or a press to force the piston pin in.

ARROW

PISTON

CONNECTING ROD

44. Install the remaining snap ring.

45. Turn the snap ring in the ring grooves until the end gaps are positioned at the bottom of the piston.

46. Repeat steps 39 through 46 for the remaining pistons.

47. Using a piston ring expander, install the spacer and two oil rings. Then install the second ring and top ring with the

manufacturing marks facing up. The second ring has a “2” followed by a letter or letters. The top ring has a “1”

followed by a letter or letters.

NOTE: The new rings may not have the same manufacturing marks as the originals.

TOP RING

MANUFACTURING

MARK

48. Rotate the rings in their grooves to make sure they do not bind.

SECOND

RING

Page 20 of 31

49. Position the ring end gaps as shown.

About 90°

‘···-…

TOP RING GAP and

SPACER RING GAP

OIL RING GAP

PISTON PIN

50. Rotate the crankshaft so that cylinders 1 and 4 are at bottom dead center (BDC).

51. Remove the connecting rod cap to piston 1, and check that the bearing is securely in place.

52. Apply new engine oil to the piston, the inside of the ring compressor, the cylinder bore, and the rod bearings

53. Position the mark to face the cam chain end of the engine block.

54. Set the piston in the ring compressor, and position the piston in the cylinder noting the rod/cap marks that you made

in step 34

RING COMPRESSOR

—–Thinner edge up.

~ ~J The ring oomp,esso, should be in this

position on the piston

before installation in

the cylinder bore.

55. Set the ring compressor on the piston bore, then push the piston in with your hands.

Page 21 of 31

56. Stop after the ring compressor pops free, and check the connecting rod-to-rod journal alignment before pushing the

piston into place.

57. Apply new engine oil to the bolt threads, then install the connecting rod cap with the bearing. Torque the bolts to 41

N·m (30 lb-ft).

58. Tighten the connecting rod bolts an additional 120°.

NOTE: If you tighten a rod bolt beyond the specified angle, remove it and repeat steps 58 and 59. Do not loosen

the bolt back to the specified angle.

120°

59. Repeat steps 47 through 58 for piston number 4.

60. Rotate the crankshaft so that cylinders 2 and 3 are at bottom dead center (BDC).

61. Repeat steps 47 through 58 for piston number 2 and 3.

62. Rotate the crankshaft several times after all connecting rods have been installed to ensure that nothing is binding.

63. Install the baffle plate, and torque the bolts to 12 N·m (8.7 lb-ft).

Page 22 of 31

64. Set the crankshaft to top dead center (TDC). Align the TDC mark (A) on the crankshaft sprocket with the pointer (B)

on the engine block.

65. Apply new engine oil to the threads of the oil pump mounting bolts (B) and the oil pump sprocket mounting bolt (C),

then loosely install the oil pump (D) with a new O-ring (E)

66. Torque the oil pump mounting bolts and the oil pump sprocket mounting bolt according to figure shown.

O-RING

(Replace.)

OIL

PUMP

MOUNTING BOLTS

44 N-m (33 lb-ft)

\

BOLTS

12 N-m

(8.7 lb-ft)

AUTOTENSIONER

BOLTS

22 N-m (16 lb-ft)

Page 23 of 31

67. Align the dowel pin (A) on the rear balancer shaft with the mark (B) on the oil pump.

DOWEL

PIN

68. Install the oil pump chain on the crankshaft sprocket with the colored link plate (A) aligned with the TDC mark (B) on

the crankshaft sprocket.

69. Set the oil pump sprocket on the oil pump chain with the punch mark aligned with the center of the colored link

plates, then install the oil pump chain sprocket to the oil pump.

OIL PUMP

CHAIN GUIDE BOLT

12 N-m (8.7 lb-ft)__._,,=

6mm LONG

PIN PUNCH

OIL PUMP

SPROCKET

MOUNTING BOLT

44 N-m (33 lb-ft)

• Apply new engine oil to the threads of the oil pump sprocket mounting bolt, then install it and torque it to 44 N·m

(33 lb-ft).

Page 24 of 31

70. Install the oil pump chain auto-tensioner, and torque the bolts to 12 N·m (8.7 lb-ft).

71. Remove the 6 mm (1/4 in.) diameter long pin punch.

72. Remove the 3.0 mm pin from the oil pump chain auto-tensioner.

3.0 mm (7/64 in.)

‘- I 1’, I DIAMETER PIN

di~

73. Remove all of the old liquid gasket from the oil pan mating surfaces, the bolts, and the bolt holes.

74. Clean and dry the oil pan mating surfaces.

75. Apply liquid gasket, P/N 08718-0004, 08718-0003, or 08718-0009, to the engine block mating surface of the oil pan

and to the inside edge of the threaded bolt holes. Install the component within 5 minutes of applying the liquid

gasket.

NOTE:

• Apply a 2.5 mm (0.098 in) diameter bead of liquid gasket along the broken line.

• If more than 5 minutes have passed after applying the liquid gasket, remove the old liquid gasket and residue,

then reapply new liquid gasket.

• Do not apply any sealant where the cam chain case is installed because the sealant will dry before you can

reinstall the case.

‘)!:_

No sealant ______.-r,

here. This area

will be sealed

after the chain

76. Install the oil pan to the engine block.

LIQUID GASKE~ 2_5 mm

~ (0.098;n.)

Page 25 of 31

77. Tighten the bolts in three steps. In the final step, torque all bolts, in sequence, to 12 N·m (9 lb-ft).

NOTE:

• Install the three bolts on the end after installing the cam chain cover.

• Wait at least 30 minutes after installing the cam chain case before filling the engine with oil.

• Do not run the engine for at least 3 hours after installing the oil pan.

These three

bolts will be

installed after

the chain cover

is installed.

78. Install a new oil filter.

79. Reinstall the clutch case cover and torque the bolts to 12 N·m (8.7 lb-ft). Reinstall the two bolts securing the oil pan

to the transmission and torque them to 64 N·m (47 lb-ft).

80. Reinstall the cylinder head with a new gasket.

• Measure the diameter of each cylinder head bolt at point A and point B.

• If either diameter is less than 10.8 mm (0.417 in), replace the cylinder head bolt.

• Apply new engine oil to the threads and under the bolt heads of all cylinder head bolts.

50 mm (1.97 in

45 mm (1.77 in)

-+

• Torque the cylinder head bolts in sequence to 39 N·m (29 lb-ft). When using a preset click-type torque

wrench, be sure to tighten slowly and do not overtighten. If a bolt makes any noise while you are torquing it,

loosen the bolt and retighten it from the first step.

Page 26 of 31

• After torquing, tighten all cylinder head bolts in two steps (90° per step) using the sequence shown above. If

you are using a new cylinder head bolt, tighten the bolt an extra 90°.

NOTE: Remove the cylinder head bolt if you tightened it beyond the specified angle, and go back to the

second bullet to remeasure the bolt. Do not loosen it back to the specified angle.

81. Reinstall the rocker arm assembly and the camshafts.

82. Reinstall the cam chain.

83. Apply liquid gasket to the oil pan where it meets the cam chain case and to the inside edge of the threaded bolt

holes. Install the cam chain case within 5 minutes of applying the liquid gasket.

:_-” 0-“-‘L'” ____I7—-~,.~. _o.. ,_~- -w~:” “~-J / –

LIQUID GAS~ 3_5 mm

~(0.138in)

Page 27 of 31

84. Install the cam chain cover.

O-RING

Replace.

MOUNTING

BOLTS

lCHAINCASE

~OILPAN

85. Reinstall the engine mount bracket and torque the bolts to 44 N·m (33 lb-ft).

44 N·m (33 lb-ft)

Page 28 of 31

• Reinstall the engine side mount using new bolts and nut.

86. Remove the engine hanger, and reinstall the subframe.

103 N.m

(75.9 lb-ft)

87. Reconnect the power steering feed line to the subframe. Torque the bolt to 9.8 N·m (7.2 lb-ft).

88. Adjust the valve clearance. Refer to the service manual for Valve Clearance Adjustment.

Valve Clearance

Intake: 0.21-0.25 mm (0.0083-0.0098 in)

Exhaust: 0.25-0.29 mm (0.0098-0.0114 in)

Specified Torque (Intake & Exhaust)

7 x0.75 mm: 14 N·m (1.4 kgf·m, 10 lbf·ft)

Apply new engine oil to the nut threads.

89. Reinstall the cylinder head cover.

90. Reinstall the connecting pipe.

91. Install the intake manifold using new gaskets.

92. Reinstall the radiator hoses and the heater hoses

93. Reinstall the EVAP canister purge valve bracket.

94. Reconnect the engine mount control solenoid connector, and the ground cables.

95. Reconnect the fuel feed hose, and reinstall the quick-connect fitting cover.

96. Reconnect the EVAP canister hose and the brake booster vacuum hose.

97. Install new gasket from TWC to A-pipe.

Page 29 of 31

98. Reinstall drive belt.

99. Fill the engine with coolant, using recovered coolant. Add new as needed.

100. Fill the engine with oil.

101. Do the battery terminal reconnection procedure.

102. Crank the engine for about 5 seconds to prime the engine with oil pressure before plugging in the ignition coils.

103. Reconnect the four ignition coil connectors

104. Do the idle learn procedure.

END.

Page 30 of 31

ORDERING PISTONS

Every engine has some combination of A- and B-sized pistons. You can determine the sizes and their locations in

the block by inspecting the markings on the timing chain end of the engine block or by looking at the pistons. If you

look at the piston, the pistons have identifiers; “A” pistons are unmarked; “B” pistons are marked with a “B”. Make

sure you order the appropriate number of each piston size before starting work.

“A” pistons are not marked on the top of the piston.

“B” pistons are always marked with a “B” stamp.

The “A” or “B” indicates the piston size.

PISTON SIZES

The “A” and “B” represents piston

size. Piston sizes can be mixed in

an engine block assembly.

PISTON SIZES

ENGINE MOUNT IDLER PULLEY

Page 31 of 31

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.