| “This site contains affiliate links for which OEMDTC may be compensated” |

A15-016

December 4, 2015

01427 Version 2

AWD Indicator Comes On and Sets DTC C1858-73

Supersedes 15-016, dated February 28. 2015, to revise the information highlighted in yellow.

AFFECTED VEHICLES

| Year | Model | Trim | VIN range |

| 2012–13 | CR-V | ALL with AWD | ALL with AWD |

REVISION SUMMARY

Under WARRANTY CLAIM INFORMATION, the template ID was added.

SYMPTOM

The electric differential pressure solenoid (EDPS) in the rear differential has excessive oil pressure, causing the AWD indicator to come on and DTC C-1858-73 (differential fluid pressure deviation high) to set.

POSSIBLE CAUSES

There is abnormal wear on the EDPS solenoid plunger.

CORRECTIVE ACTION

Replace the EDPS solenoid.

PARTS INFORMATION

| Part Name | Part Number | Quantity |

| Solenoid Assembly | 48350-R7L-013 | 1 |

| Bolt (12-point, 8 mm x 21 mm) | 90113-S10-000 | 4 |

| Flange Bolt (8 mm x 14 mm) | 95701-08014-08 | 2 |

| Drain Washer (20 mm) | 94109-20000 | 1 |

| Drain Washer (18 mm) | 90471-PX4-000 | 1 |

| O-Ring (7.7 mm x 2.3 mm) | 91301-PC9-003 | 1 |

| O-Ring (28.4 mm x 2.4 mm) | 91306-R7L-003 | 1 |

| Clip | 91540-STK-003 | 1 |

| Liquid Gasket | 08718-0004 | 1 |

Honda Dual Pump Fluid II Dual Pump Fluid II | 08200-9007 | 2 |

WARRANTY CLAIM INFORMATION

The normal warranty applies.

| Operation Number | Description | Flat Rate Time | Template ID | Failed Part Number |

| 2191Y0 | Replace the EDPS solenoid. | 1.4 hrs | 15-016A | 48350-R7L-013 |

Defect Code: 03217

Symptom Code: 03214

Skill Level: Repair Technician

REPAIR PROCEDURE

- Raise the vehicle on a lift and make sure it is securely supported.

- Shift into Neutral.

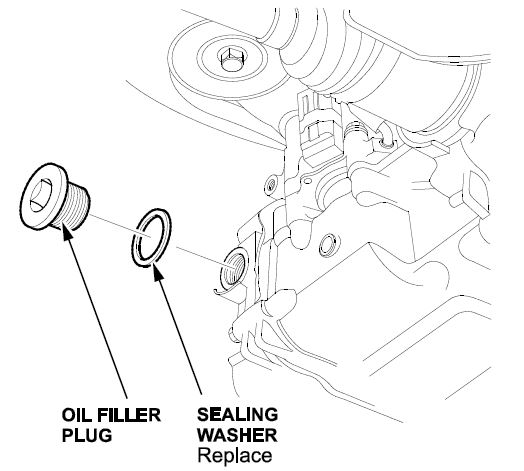

- Remove the oil filler plug and sealing washer from the rear differential.

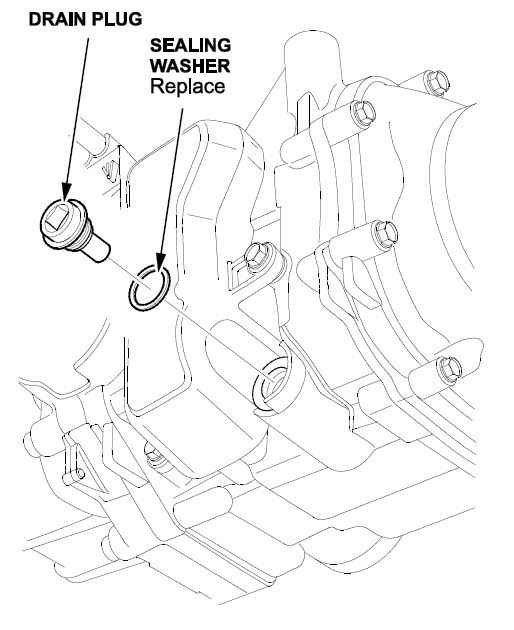

- Remove the drain plug and sealing washer, then drain the rear differential fluid.

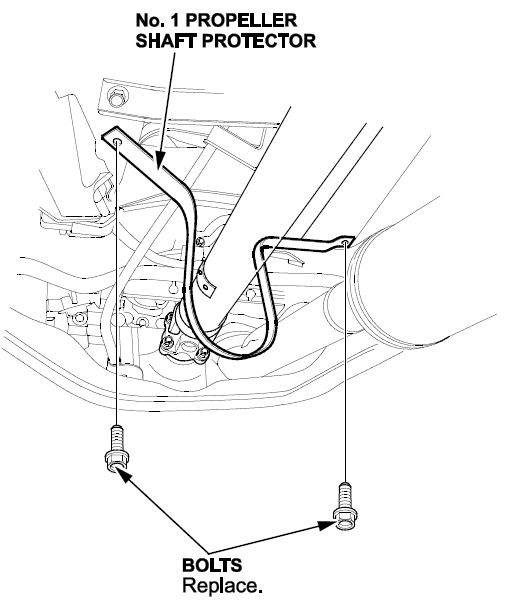

- Remove the No. 1 propeller shaft protector.

- Disconnect the propeller shaft from the rear differential:

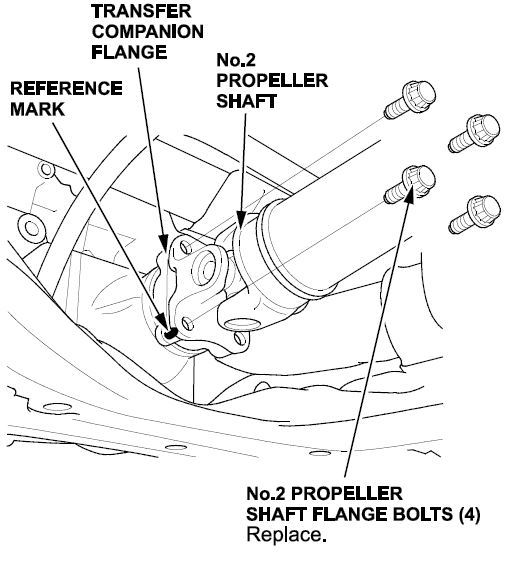

- Make a reference mark across the No. 2 propeller shaft and the transfer companion flange.

- Remove the propeller shaft flange bolts.

- Separate the propeller shaft from the rear differential.

- Tie off the propeller shaft with an appropriate size nylon strap.

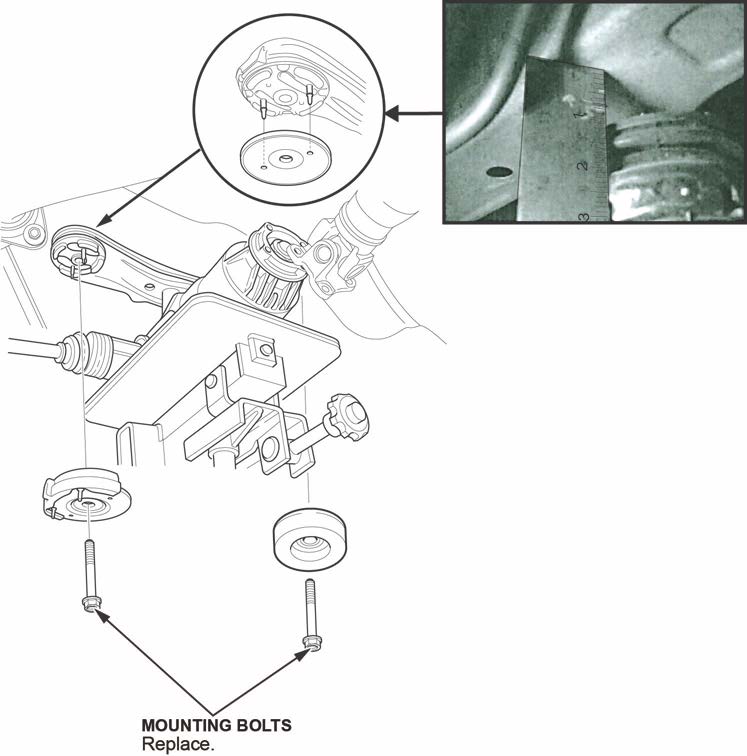

- Support the rear differential with a jack. Remove the mounting bolts and lower the differential about 1 inch.

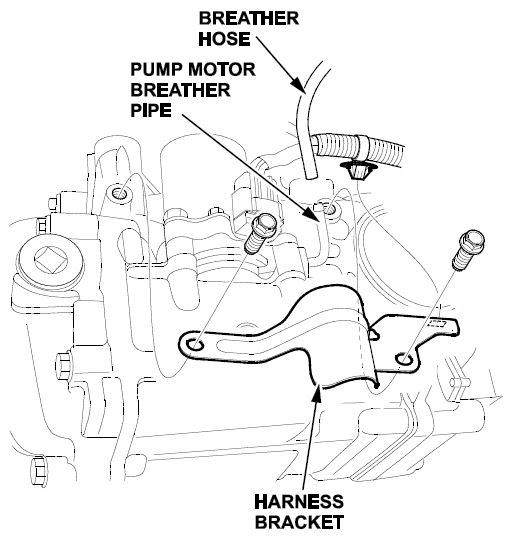

- Disconnect the breather hose from the pump motor breather pipe, then remove the harness bracket.

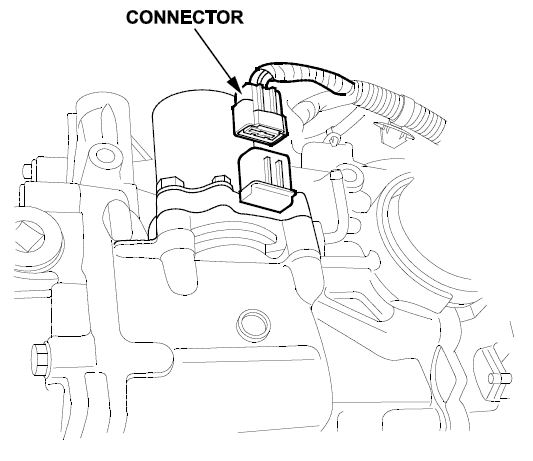

- Disconnect the connector.

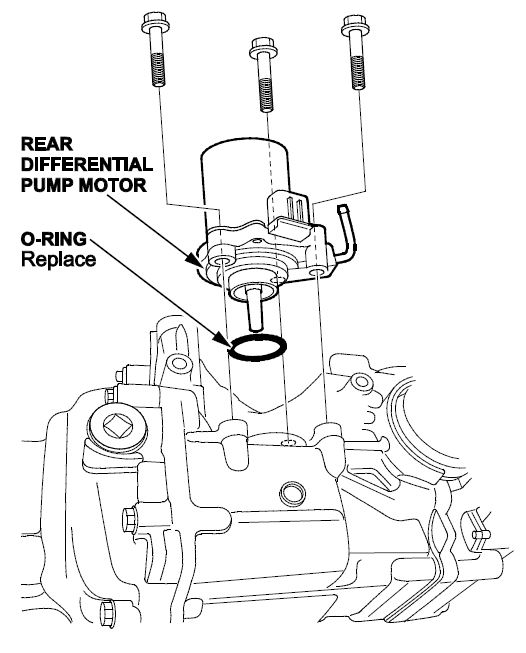

- Remove the rear differential pump motor and the O-ring.

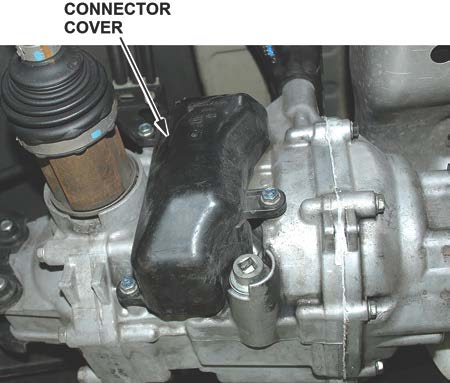

- Remove the connector cover.

- Disconnect the EPDS connector, then remove the solenoid connector.

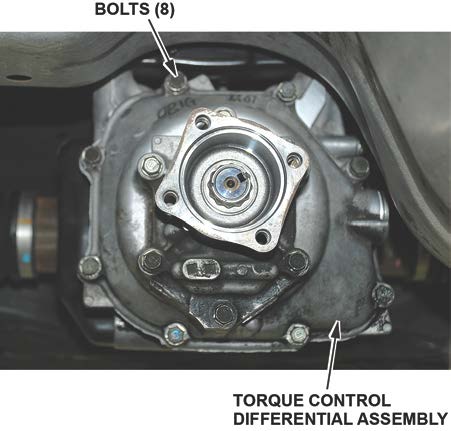

- Remove the bolts, then remove the torque control differential assembly.

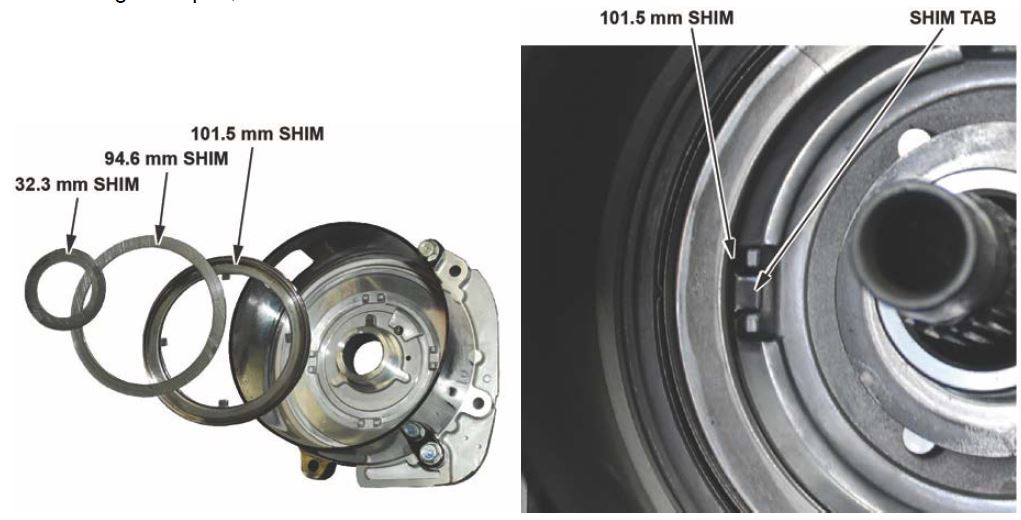

- Remove the three shims from the pump housing assembly and note the order from which they were removed.

NOTE: Make sure the large 101.5 mm shim fits into the tabs on reassembly. If the shims are removed or fall out while doing the repair, note the orientation of the shims and reinstall in the order shown.

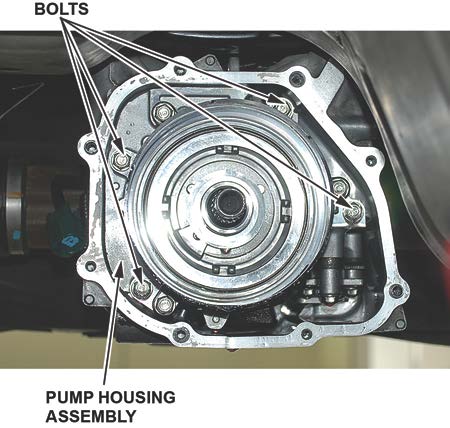

- Remove the four bolts from the pump housing assembly to remove it.

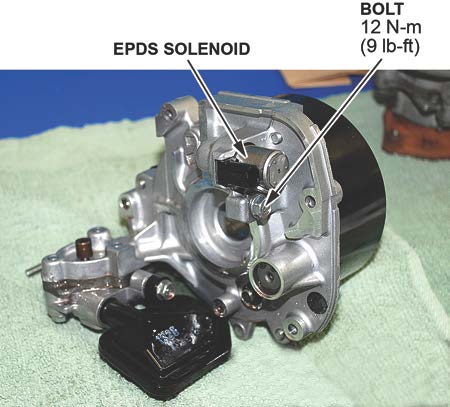

- Remove the EPDS solenoid.

NOTE: If Service Bulletin 14-047, Noise From the Rear Differential, was done, make sure the intermediate drive joint does not fall out when handling the pump housing.

- Install the new EPDS solenoid and torque the bolts to 12 N·m (9 lb-ft).

- Replace the O-ring with a new one.

- Install the pump housing assembly and torque the bolts to 12 N·m (9 lb-ft).

- Install the shims in the order of removal and make sure the tabs are in place.

- Remove the old gasket and any dirt and oil from the mating surface.

- Apply liquid gasket evenly to the entire sealing surface and install the component within 5 minutes of applying it.

NOTE: Allow the liquid gasket to cure for 30 minutes after assembly before filling the differential with the recommended fluid.

- Install the torque control differential assembly and torque the bolts to 12 N·m (9 lb-ft).

- Install the solenoid connector and the EPDS connector.

- Install the connector cover.

- Install the rear differential pump motor with a new O-ring and torque the bolts to 12 N·m (9 lb-ft).

- Connect the connector.

- Install the harness bracket and the breather hose to the pipe.

- Install the new mounting bolts and torque them to 44 N·m (32 lb-ft).

- Install the propeller shaft:

- Attach the propeller shaft to the rear differential companion flange by aligning the reference mark you made in step 6.

- Install the new bolts and torque them to 32 N·m (24 lb-ft).

- Install the propeller shaft protector and torque the bolts to 22 N·m (16 lb-ft).

- Clean the drain plug, and install it with a new sealing washer, then torque it to 47 N·m (35 lb-ft).

- Refill the differential to the proper level.

- Install the oil filler plug with a new sealing washer and torque the plug to 47 N·m 35 lb-ft).

- Connect the HDS to the DLC.

- Turn the ignition to ON.

- Make sure the HDS communicates with the vehicle. If it does not communicate, go to the DLC circuit troubleshooting.

- Select REAL TIME AWD SYSTEM, ADJUSTMENT, and AIR BLEEDING.

NOTE: See the HDS Help menu for specific instructions.

END

No products found.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.