| “This site contains affiliate links for which OEMDTC may be compensated” |

A99-065

December 11, 2001

Applies To: 1999–2001 Odyssey – ALL

Inaccurate Odyssey Fuel Gauge

(Supersedes 99-065, 1999 Odyssey: Inaccurate Fuel Gauge, dated August 17, 1999)

SYMPTOM

The fuel gauge needle doesn’t point to “F” after you fill the fuel tank, and/or the fuel gauge reading is not accurate when the tank is between 1/2 and full.

PROBABLE CAUSE

Sulfur deposits from the fuel affect the resistance of the fuel gauge sending unit.

CORRECTIVE ACTION

Replace the fuel gauge sending unit.

PARTS INFORMATION

| Description | Part Number | |

| Fuel Gauge Sending Unit: P/N | 17630-S0X-A03 | H/C 6786289 |

| Base Gasket: P/N | 17574-S1A-E01 | H/C 5928122 |

| Fuel Line Retainer (return): P/N | 17711-S0X-931 | H/C 5928312 |

| Fuel Line Retainer (feed): P/N | 17711-S0X-003 | H/C 5928296 |

| Sealing Washer: P/N | 16705-PD1-003 | H/C 1855675 |

| Sealing Washer: P/N | 90428-PD6-003 | H/C 2128429 |

REQUIRED SPECIAL TOOLS

| Description | Tool Number |

| Fuel Sender Wrench: | 07XAA-001010A |

WARRANTY CLAIM INFORMATION

In warranty: The normal warranty applies.

| Operation Number: | 310120 |

| Flat Rate Time: | 1.0 hour |

| Failed Part: | P/N 17630-S0X-A02 H/C 6183305 |

| Defect Code: | 039 |

| Contention Code: | B99 |

| Template ID: | 99-065A |

| Skill Level: | Repair Technician |

Out of warranty: Any repair performed after warranty expiration may be eligible for goodwill consideration by the District Service Manager or your Zone Office. You must request consideration, and get a decision, before starting work.

REPAIR PROCEDURE

- Remove the second row seats.

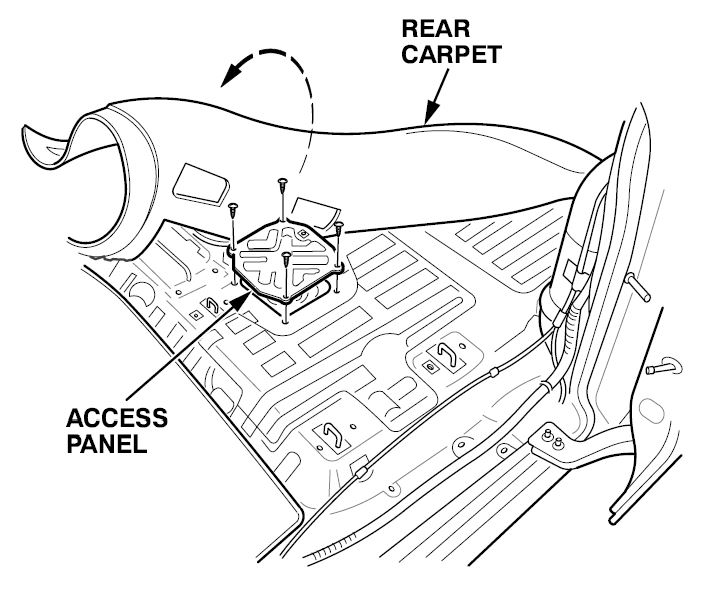

- Pull back enough of the rear carpet to expose the access panel on the floor.

- Remove the access panel.

- Make sure the ignition switch is off, then disconnect the 5P connector from the top of the fuel pump assembly.

- Remove the fuel fill cap.

- Relieve the fuel pressure (see page 11-208 of the 1999–02 Odyssey Service Manual).

NOTE: Whenever you relieve fuel pressure, replace the two sealing washers for the fuel pulsation damper.

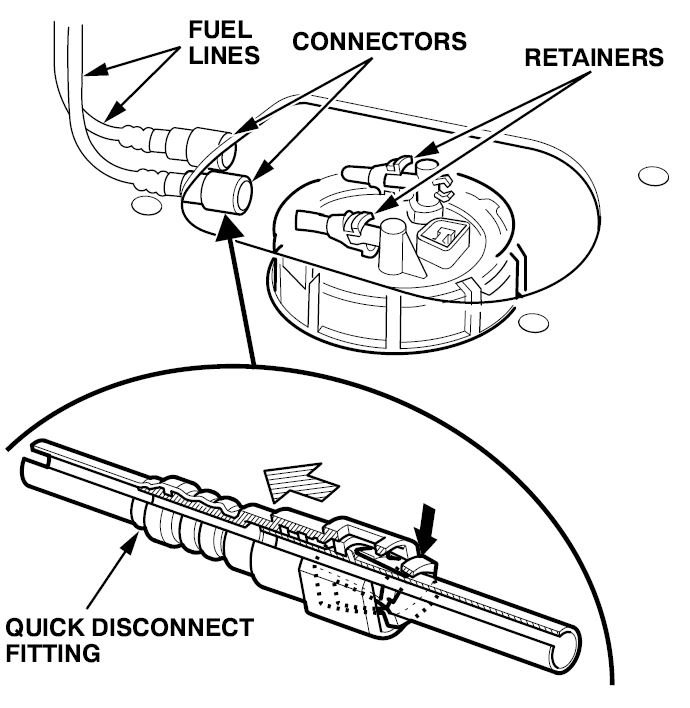

- Disconnect the two fuel lines (quick-disconnect fittings) from the fuel pump assembly: Hold the connector side of the fitting, squeeze the tabs on the retainer, and pull the connector off the fuel line.

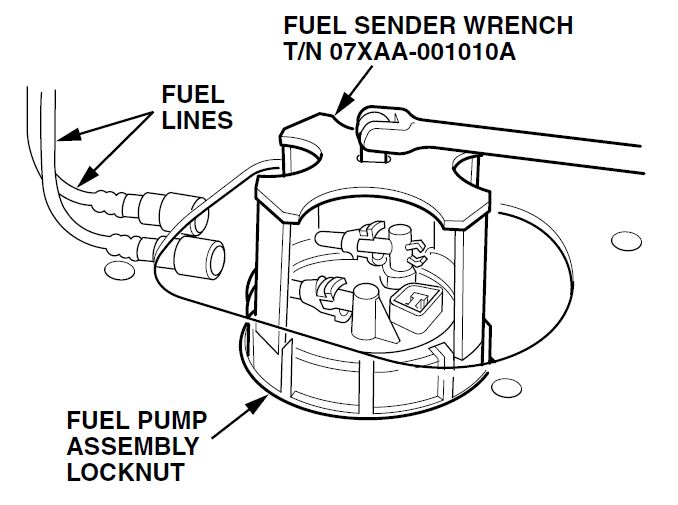

- Remove the fuel pump assembly locknut with the special tool, then lift the fuel pump assembly out of the fuel tank.

- Discard the base gasket between the fuel pump assembly and the fuel tank.

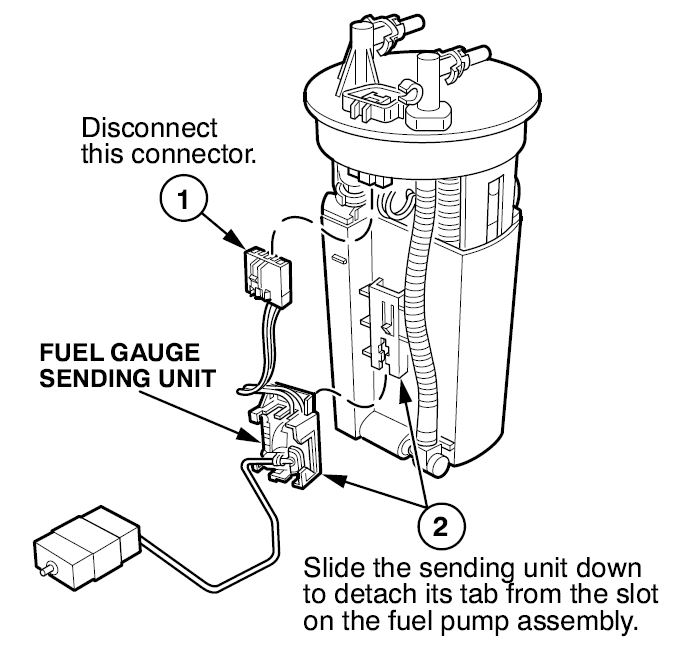

- Remove the fuel gauge sending unit from the fuel pump assembly.

- Install the new fuel gauge sending unit.

- Place a new base gasket around the opening in the tank, then carefully insert the fuel pump assembly into the opening.

- Install the locknut over the fuel pump assembly, then use the special tool to torque the locknut to 93 N.m (69 ft-lb).

- Remove and discard the two fuel line retainers from the top of the fuel pump assembly.

- Insert new fuel line retainers into the connector side of the quick disconnect fittings, then connect the fuel lines to the fuel pump assembly (see pages 11-218 and 11-219 of the service manual).

- Connect the 5P connector to the fuel pump assembly.

- Turn the ignition switch to ON (II), and make sure there are no leaks at the fuel lines and the base gasket.

- Turn the ignition switch off, then install the access panel, the carpet, and the seats.

- Install the fuel fill cap, and tighten it until it clicks at least three times.

Loading...

Loading...