| “This site contains affiliate links for which OEMDTC may be compensated” |

| Model | Applicable To | File Under | Bulletin No. | Issue Date |

| 1990 – 93 ACCORD | ALL | ENGINE | A96-005 | JAN 22, 1996 |

Excessive Idle Vibration or “Click” Sound

SYMPTOMS

- Engine vibration at idle.

or

- A single “click” or “pop” sound is heard when coming to a stop (automatic transmission only).

PROBABLE CAUSES

Idle Vibration:

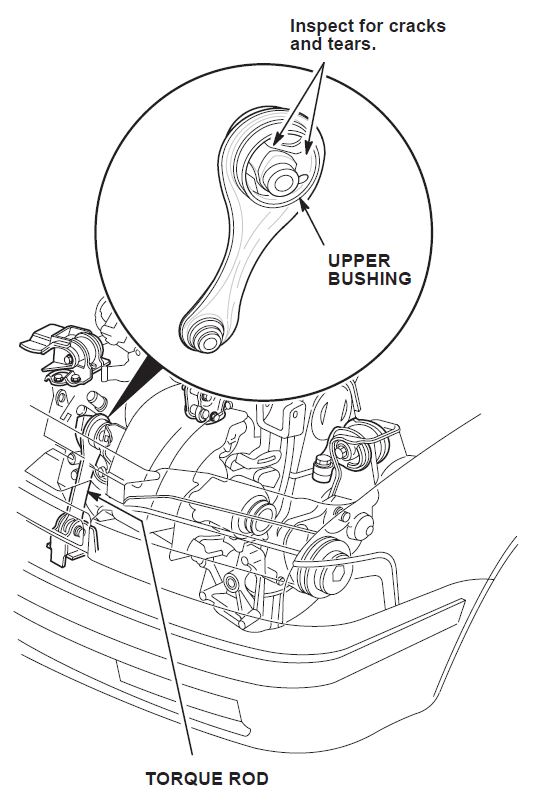

- The upper bushing in the torque rod is cracked or torn (manual or automatic transmission).

- The vacuum-controlled rear engine mount is defective (automatic transmission only).

“Click” Sound (automatic transmission only): - The vacuum-controlled rear engine mount is defective.

PARTS INFORMATION

| Torque rod: | ||

| For manual transmission P/N | 50830-SM4-020 | H/C 3594991 |

| For automatic transmission P/N | 50830-SM4-A81 | H/C 3594983 |

| Vacuum-actuated rear engine mount: P/N | 50810-SV4-J82 | H/C 4710133 |

CORRECTIVE ACTION

- Idle Vibration: Begin with Torque Rod Inspection.

- “Click” Sound: Begin with Diagnosis B.

Torque Rod Inspection

- Inspect the torque rod upper bushing for cracks or tears. On A/T-equipped models, remove the upper mounting bolt and rotate the torque rod away from the engine.

- If the bushing is bad, continue to step 2 to replace the torque rod.

- If the bushing is OK, and the vehicle has an automatic transmission, go to Diagnosis A.

- If the bushing is OK, and the vehicle has a manual transmission, investigate other causes.

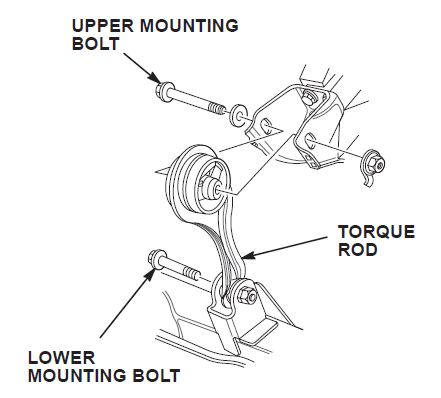

- Remove the upper mounting bolt (if not done instep 1). Remove the lower mounting bolt. Remove the torque rod.

- Install the new torque rod (see PARTS INFORMATION). Torque both mounting bolts to 65 N⋅m (47 lb-ft).

NOTE: The upper mounting bolt should easily slide into the torque rod. If it does not, the front beam may be bent.

- Start the engine and check for idle vibration.

- Manual Transmission: If idle vibration is still excessive, investigate other causes.

- Automatic Transmission: If idle vibration is still excessive, go to Diagnosis A.

Diagnosis A (Excessive Idle Vibration)

- Warm the engine to normal operating temperature (cooling fan comes on at least twice).

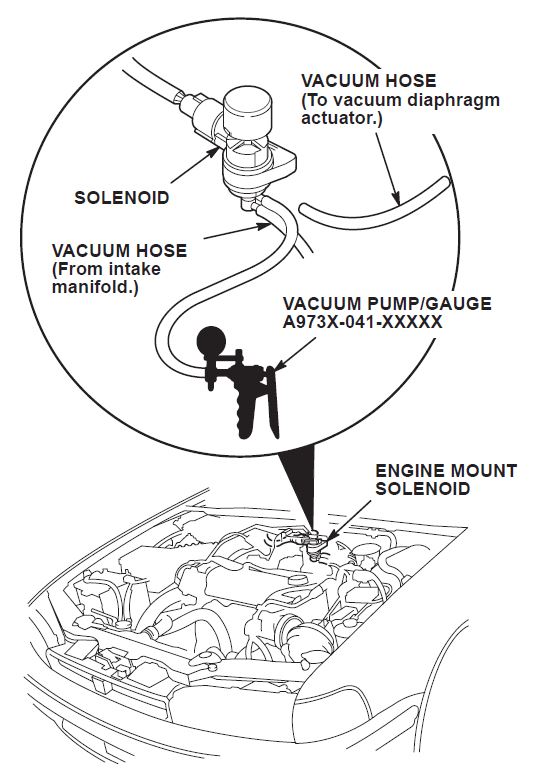

- Disconnect the upper hose from the engine mount solenoid. Attach a vacuum gauge to the solenoid.

- With engine speed at 770 rpm or less, check for manifold vacuum.

- If there is no vacuum, troubleshoot the engine mount control system (see section 23 of the appropriate service manual).

- If there is vacuum, continue to step 4.

- Disconnect the vacuum gauge from the engine mount solenoid and plug the hose port.

- Connect a vacuum pump to the upper hoseyou disconnected in step 2. Apply 15 inches of vacuum for several seconds.

- If there is a vacuum leak, inspect the hose and engine mount diaphragm.

- If there is no vacuum leak, continue to step 6.

- Turn on the air conditioning and put the transmission in Drive.

- Have an assistant apply 15 inches of vacuum for approximately 10 seconds, then release the vacuum for 10 seconds. Repeat this several times.

- If the level of idle vibration changes with the vacuum application, investigate other causes for the idle vibration.

- If the level of idle vibration does not change, go to Engine Mount Replacement.

Diagnosis B (“Click” Sound)

- Test drive the vehicle and verify that a single“click” or “pop” sound is heard when coming to a stop.

- Disconnect the upper hose from the enginemount solenoid. Plug the hose and the port on the solenoid.

- Drive the vehicle again and listen for the same sound.

- If the sound is still there, investigate other causes.

- If the sound has disappeared, go to Engine Mount Replacement.

Engine Mount Replacement

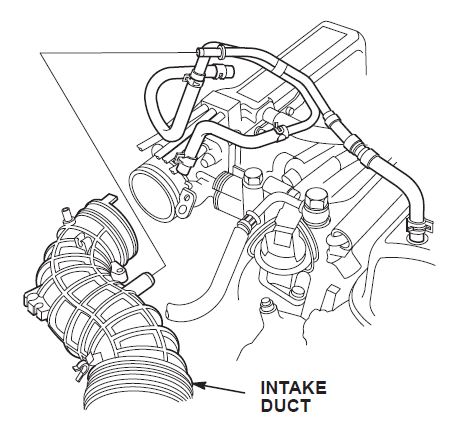

- Remove the air intake duct.

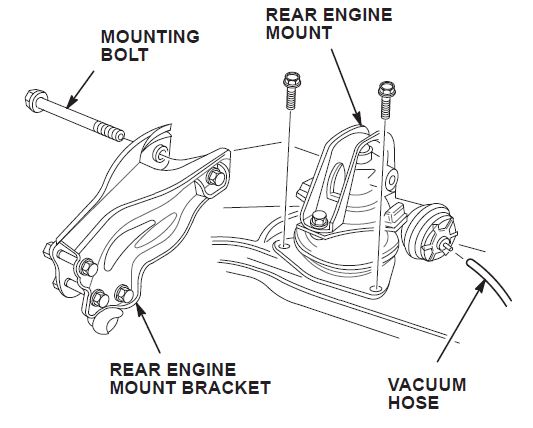

- Disconnect the vacuum hose from the rear engine mount diaphragm. Remove the mounting bolt.

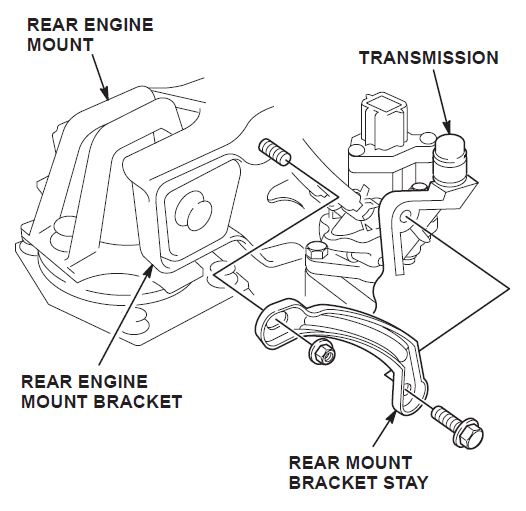

- Remove two of the three rear engine mount mounting bolts.

- Remove the bracket between the engine and transmission.

- Raise the vehicle on a hoist.

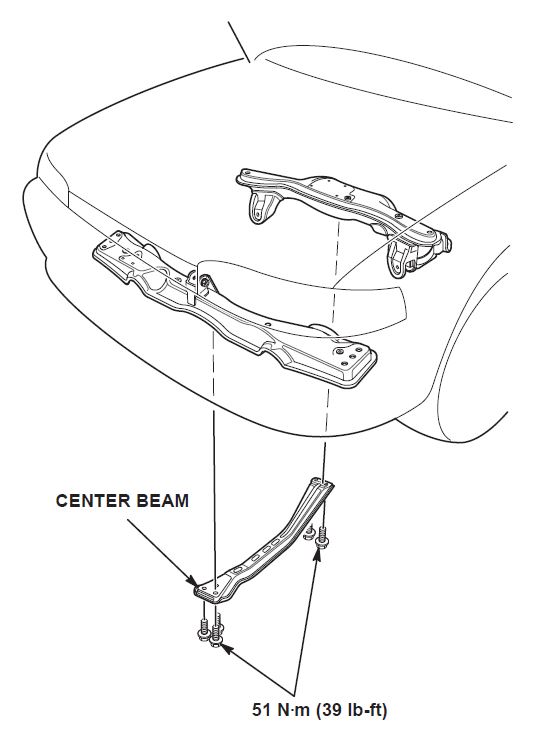

- Remove the center beam (five bolts).

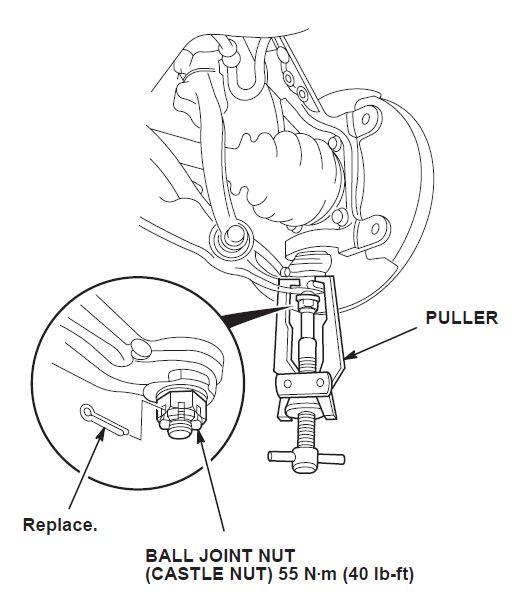

- Remove the cotter pin and castle nut from the left lower control arm. Use the special tool to separate the lower control arm from the steering knuckle.

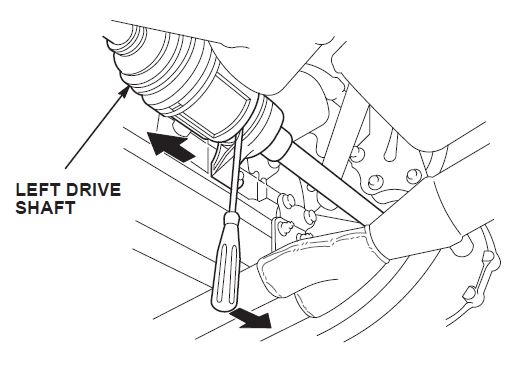

- Disconnect the left drive shaft from the intermediate shaft.

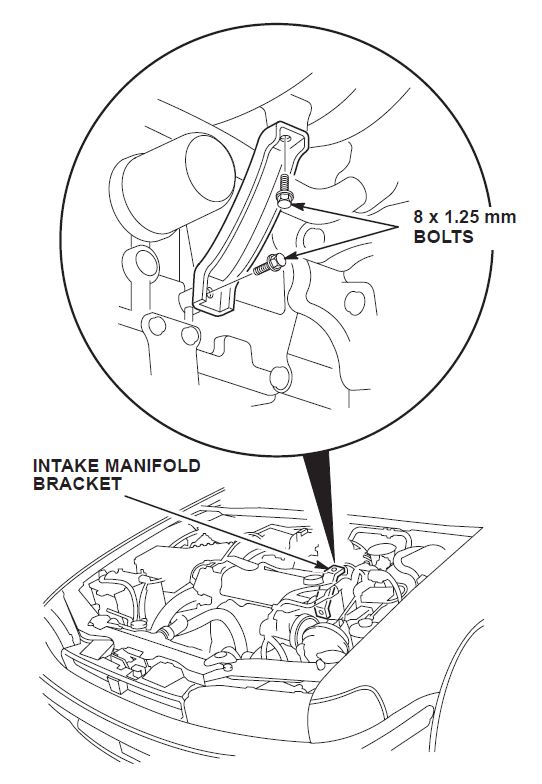

- Remove the intake manifold bracket.

- Remove the remaining rear engine mount mounting bolt.

- Remove the oil filter.

- EX model only: Remove the oxygen sensor.

- Remove the rear engine mount by sliding it to the left side of the vehicle.

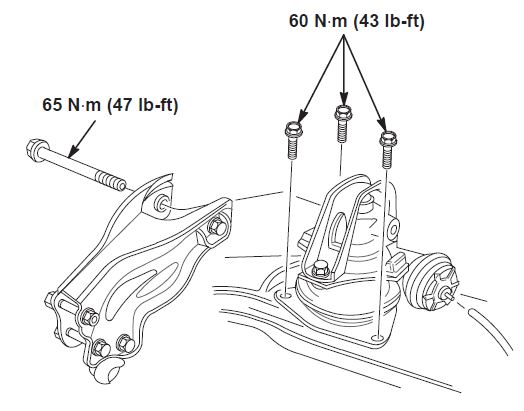

- Install the new rear engine mount. Torque the bolts as shown.

- Reinstall all removed parts.

WARRANTY CLAIM INFORMATION

In warranty: The normal warranty applies.

Out of warranty: Any repair performed after warranty expiration may be eligible for goodwill consideration by the District Service Manager or your Zone Office. You must request consideration, and get a decision, before starting work.

| OPERATION NUMBER | DESCRIPTION | FLAT RATE TIME | TEMPLATE ID |

| 112113 | Inspect and replace torque rod, manual transmission | 0.5 hour | 96-005A |

| 112113 | Inspect and replace torque rod, automatic transmission | 0.5 hour | 96-005B |

| 112114 | Diagnose and replace rear engine mount | 1.9 hours | 96-005C |

Failed part: P/N 50830-SM4-A81 H/C 3594983

Defect code: 042

Contention code: B07

Loading...

Loading...