| “This site contains affiliate links for which OEMDTC may be compensated” |

Service Bulletin

B20-026

June 19, 2020

Version 2

Safety Recall: 2019 RDX Fuel Pump Motor

Supersedes A20-026, dated May 29,2020, to revise the information highlighted in yellow

AFFECTED VEHICLES

| Year | Model | Trim Level | VIN Range |

| 2019 | RDX | ALL | Check the iN VIN status for eligibility. |

REVISION SUMMARY

- Under PARTS INFORMATION, additional text was added.

- Under REPAIR PROCEDURE step 16, the NOTES and substep 16.2 were revised.

BACKGROUND

Due to swelling of the fuel pump motor impeller, the fuel pump may seize and stop working. If this occurs, the engine may not start, or the engine could stall while driving, possibly increasing the risk of a crash.

CLIENT NOTIFICATION

Owners of affected vehicles will be sent a notification of this campaign.

Do an iN VIN status inquiry to make sure the vehicle is shown as eligible.

Some vehicles affected by this campaign may be in your new or used vehicle inventory.

Failure to repair a vehicle subject to a recall or campaign may subject your dealership to claims or lawsuits from the client or anyone else harmed as a result of such failure. To see if a vehicle in inventory is affected by this safety recall, do a VIN status inquiry before selling it.

CORRECTIVE ACTION

Replace the fuel pump motor.

PARTS INFORMATION

NOTE

Due to limited supply, this will be a controlled part and will require a valid VIN when ordering.

| Part Name | Part Number | Quantity |

| Fuel Pump Motor Kit | 06170-TJB-306 | 1 |

For dealers experiencing a strong fuel smell from storing a fuel pump motor replaced under this service bulletin, the fuel pump motor may be disposed of immediately in accordance with local regulations. This only applies to the fuel pump motor replaced under this service bulletin. The published retention policy remains in effect for all other parts. If you have any questions about this exception or other parts retention issues, contact the WPI Administrative Office at 937-642-2737.

TOOL INFORMATION

| Part Name | Part Number | Quantity |

| Fuel Sender Wrench | 070AA-TLA0100 | 1 |

WARRANTY CLAIM INFORMATION

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 3101HK | Replace the fuel pump motor. | 1.2 hr | 6FE00 | S7D00 | B20026A | 17045-TJB-A03 |

REPAIR PROCEDURE

| WARNING |

| Fuel pump motor removal exposes fuel, which can ignite, causing a fire or explosion.

This can cause serious injury or death. Always work in a well-ventilated area and keep sparks or open flames away. |

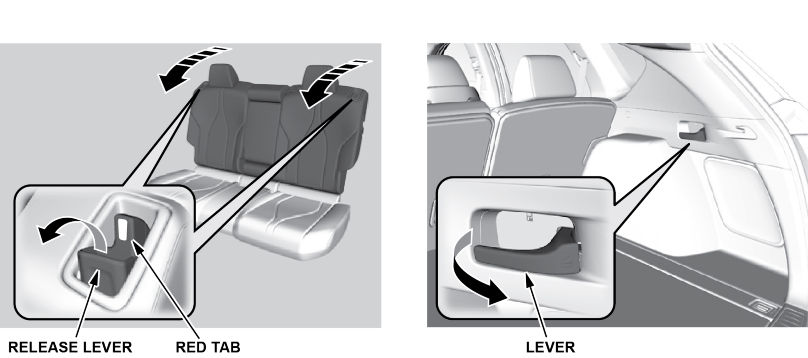

- Fold down the passenger-rear seat back.

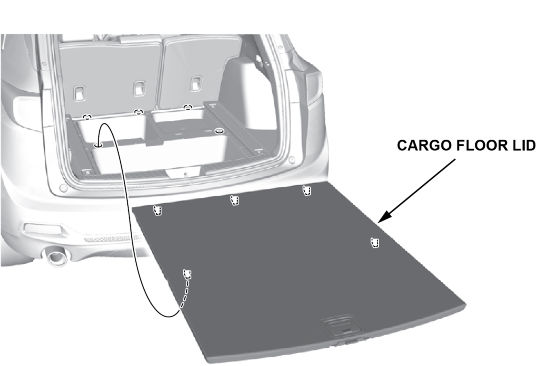

- Remove the cargo floor lid.

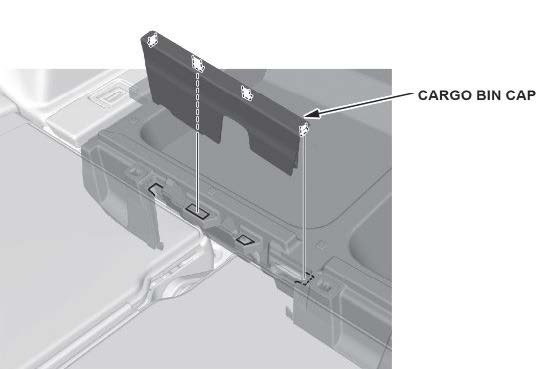

- Remove the cargo bin cap.

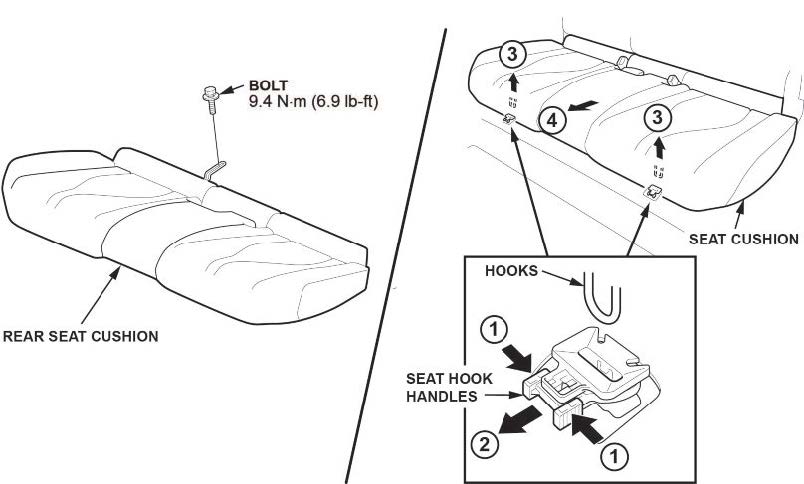

- Remove the rear seat cushion.

4.1 Remove the bolt.

4.2 Fold up the passenger-rear seat back to the upright position.

4.3 While pushing down on the rear seat cushion, pull the seat hook handles to release the hooks.

4.4 Pull back the seat cushion to pull off the seat belt buckles from the slits in the seat cushion.

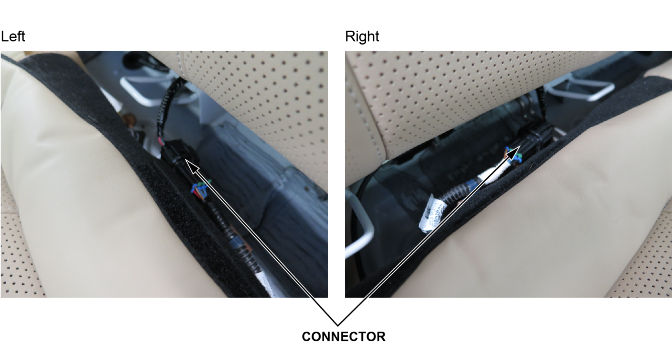

4.5 With rear seat heaters: Disconnect the connectors.

4.6 Remove the rear seat cushion.

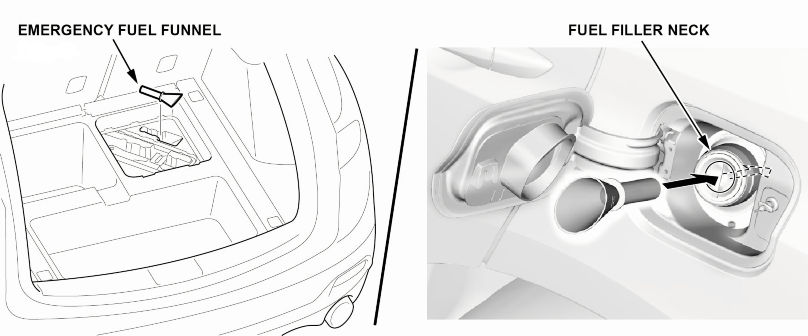

- Insert the emergency fuel funnel into the fuel filler neck to relieve the pressure in the fuel tank.

NOTE

The emergency fuel funnel is in the cargo tool box.

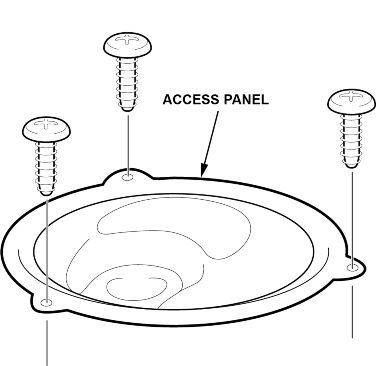

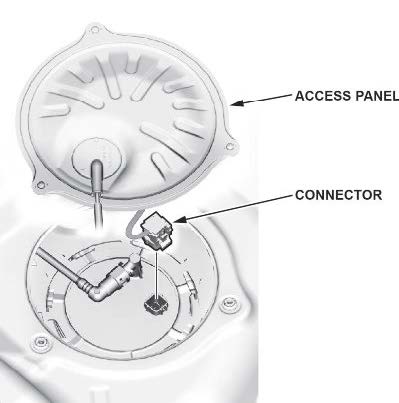

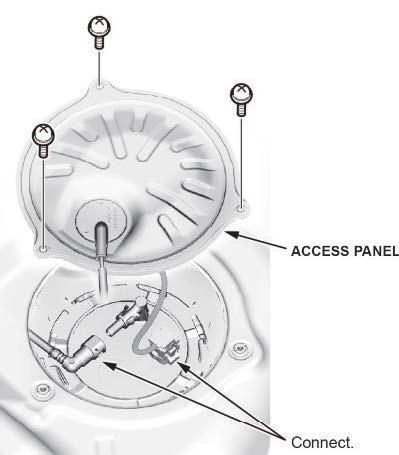

- Remove the fuel tank unit access panel.

- Disconnect the fuel tank unit connector.

- Start the engine, and let it idle until it stalls.

- Turn the ignition to OFF.

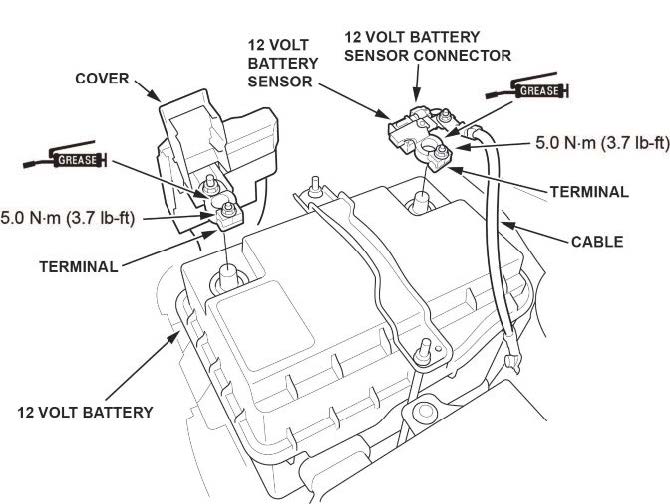

- Disconnect the 12-volt battery terminals.

10.1 Make sure the ignition is turned to OFF.

10.2 Disconnect and isolate the 12-volt battery sensor with the cable attached, from the 12-volt battery.

NOTES

- Always disconnect the negative terminal first.

- To protect the terminal connector from damage, do not hold it when removing the terminal.

- Do not disconnect the 12-volt battery sensor from the cable.

10.3 Open the cover. If necessary, remove the cover.

10.4 Disconnect the positive terminal from the 12-volt battery.

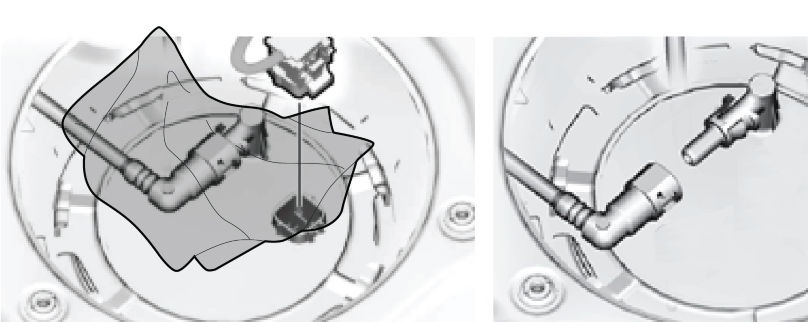

- Place a rag or shop towel over the quick-connect fitting, and disconnect it.

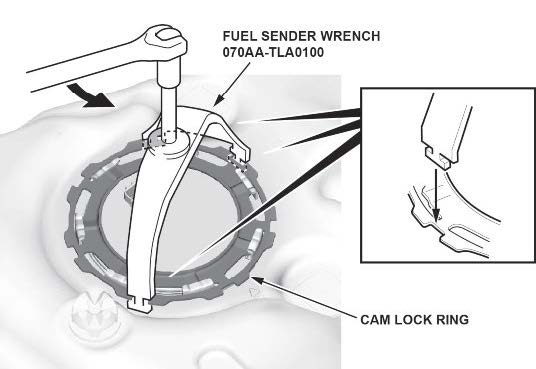

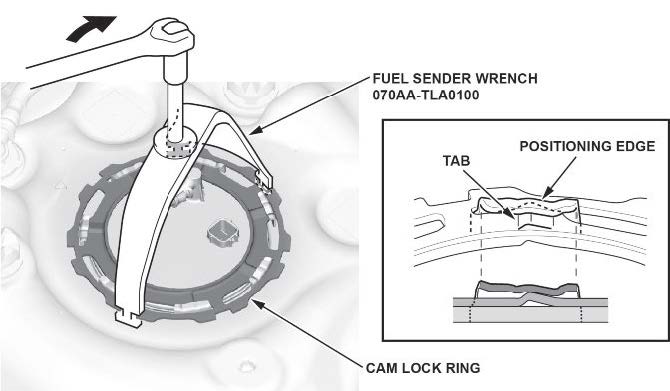

- Remove the fuel tank unit cam lock ring using the fuel sender wrench (T/N 070AA-TLA0100

).

).

NOTE

Keep the fuel sender wrench from floating.

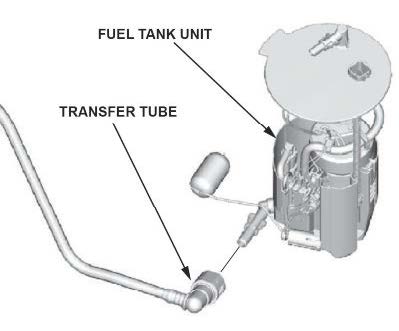

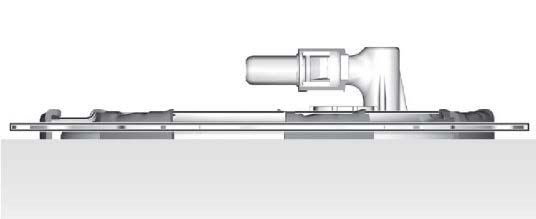

- Slightly pull up and tilt the fuel tank unit, then disconnect the transfer tube.

NOTE

The gasoline in the fuel tank unit will drain out once the transfer tube is disconnected. Make sure it pours back into the tank.

- Remove the fuel tank unit.

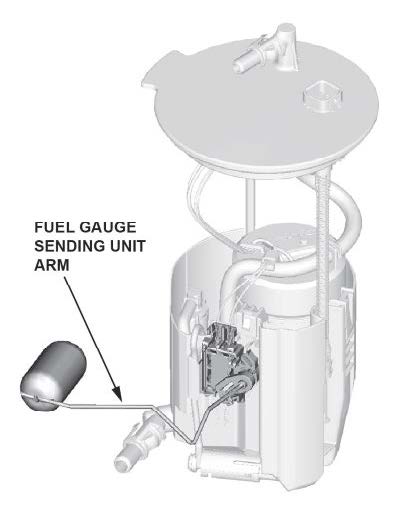

NOTE

Be careful not to bend or twist the fuel gauge sending unit arm excessively.

- Disassemble the fuel tank unit.

15.1 Prepare the fuel pump and parts to be replaced.

NOTE

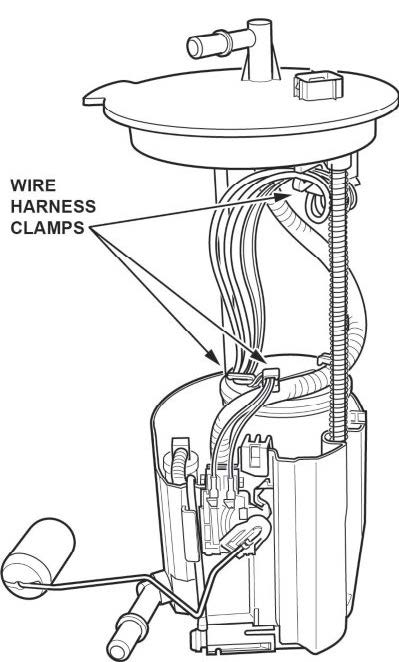

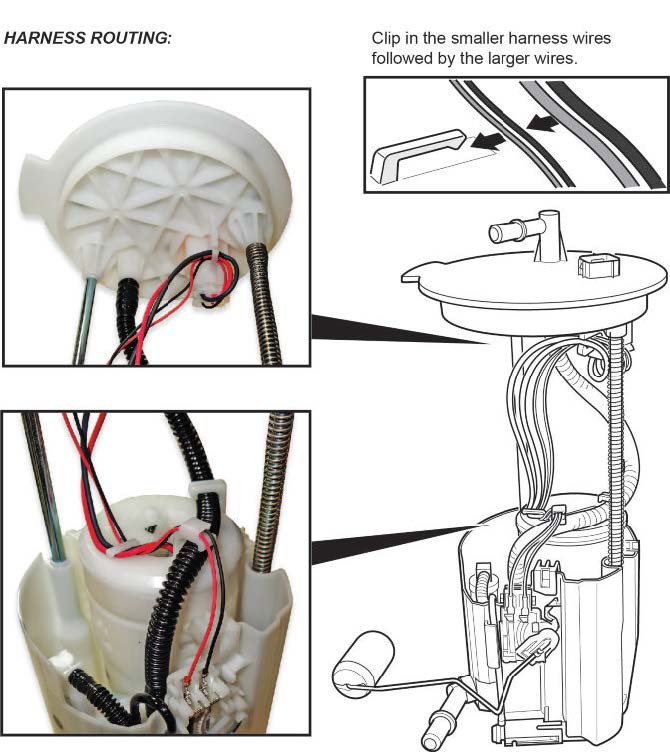

Take a photo of the fuel tube and wire harness, and note their routing for assembly. There are various types of routing.

15.2 Spread the wire harness clamps, and remove the wire harness.

NOTES

- Make sure not to damage the wire harness.

- Do not spread the clamps too wide. Spreading the clamps too wide may damage them.

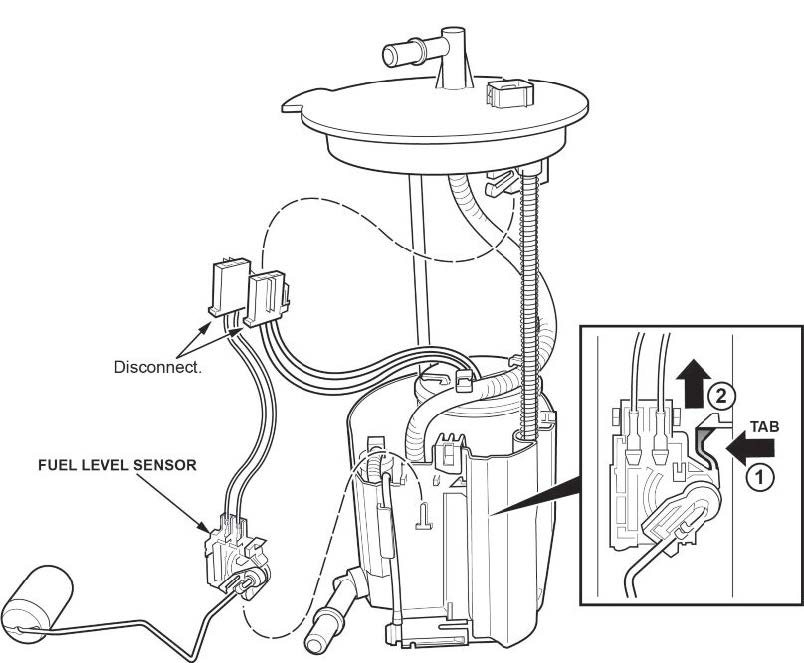

15.3 Remove the fuel level sensor.

-

-

- Disconnect the harnesses.

-

-

-

- Press the tab to release the lock (1). Then, push up on the fuel gauge sending unit (2).

- Remove the fuel level sensor from the fuel tank unit.

-

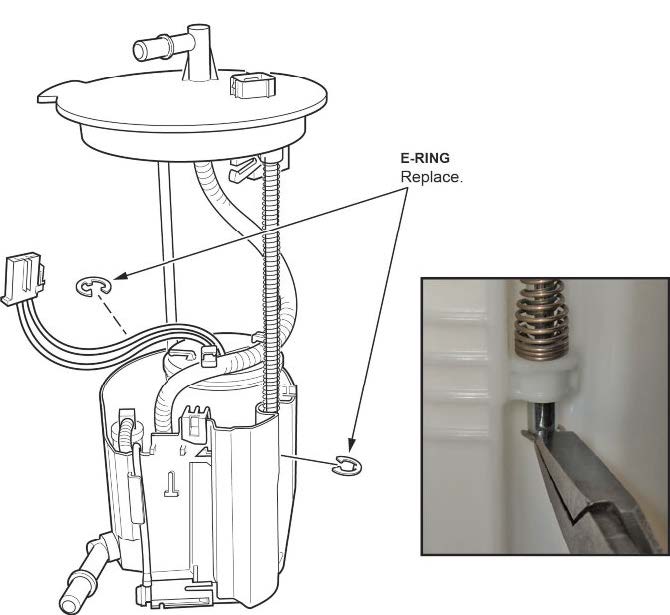

15.4 Remove the E-ring, and throw it away. Do not use it again.

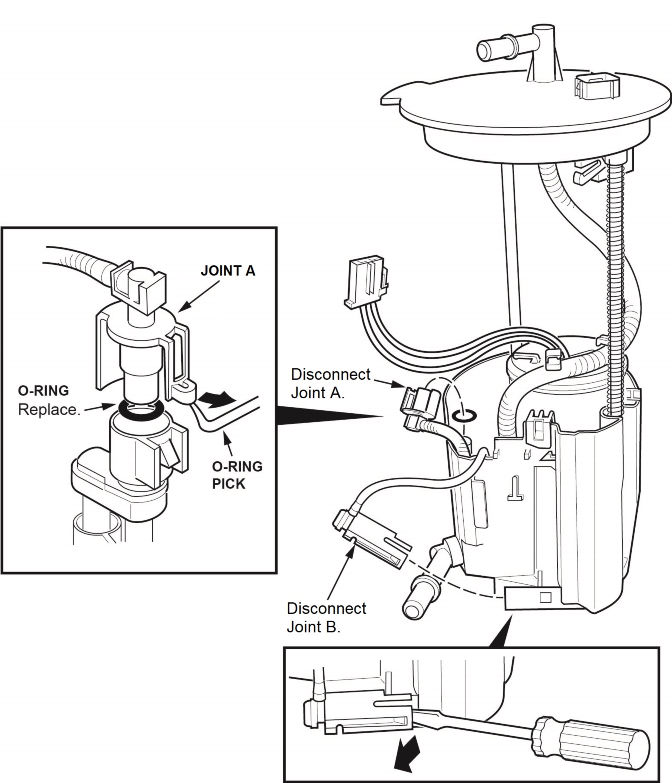

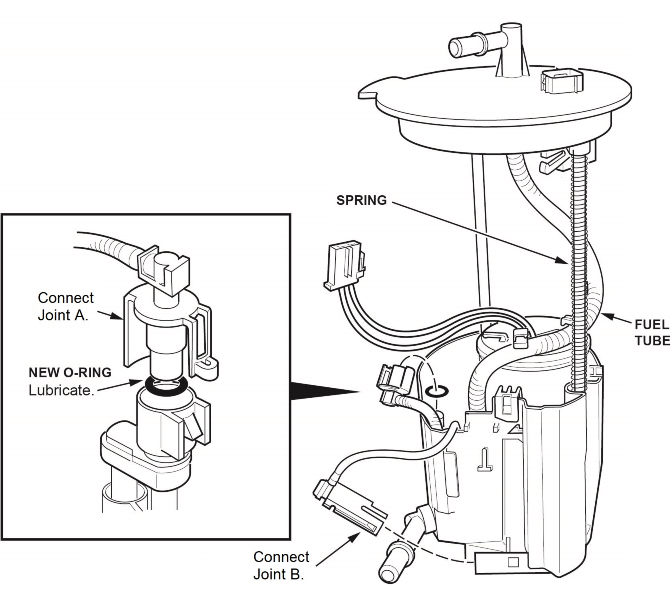

15.5 Use an O-ring pick to disconnect Joint A inside the reservoir.

NOTE

If the O-ring remains inside the joint, use a flathead screwdriver wrapped in protective tape to remove it. Take care not to damage the O-ring seat section.

15.6 Disconnect Joint B from the bottom of the reservoir.

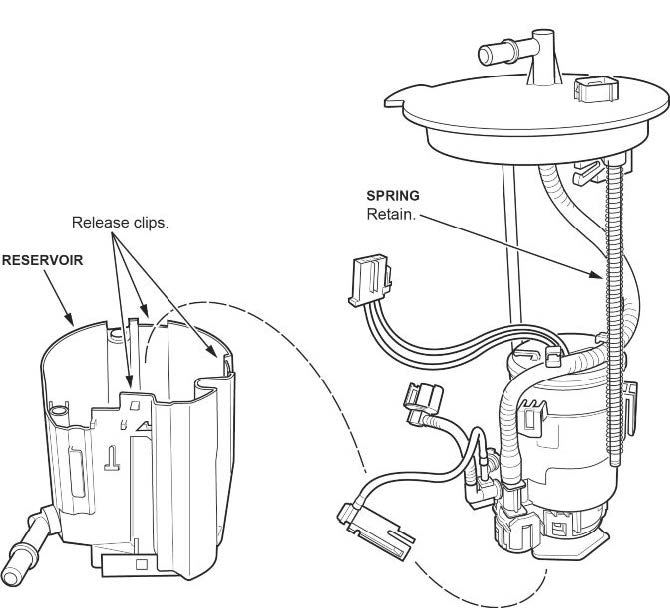

15.7 Remove the fuel filter assembly from the reservoir by releasing the three clips.

NOTES

- Do not spread the clips too wide. Spreading them too wide may damage them.

- The spring may slide off the sliding shaft. Retain this spring. It will be used during assembly.

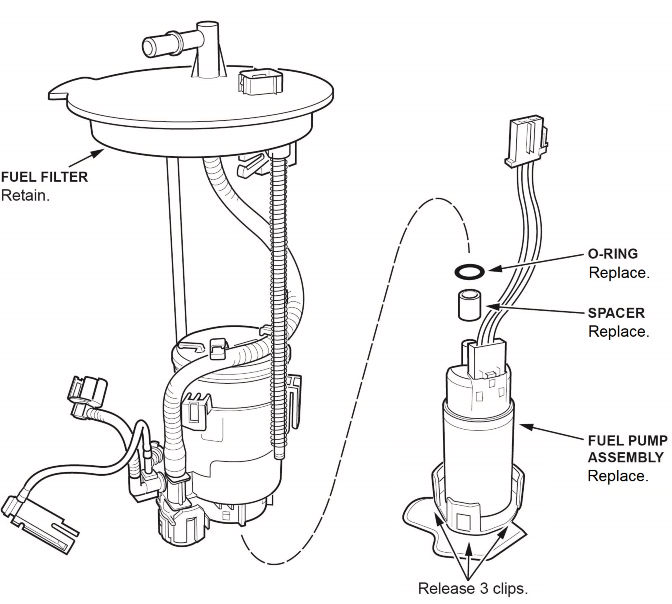

15.8 Remove the fuel pump assembly from the fuel filter.

-

-

- Release the three clips at the base of the fuel pump assembly.

- Pull the fuel pump assembly out of the fuel filter.

- If the O-ring remains on the fuel filter, use a flat-tip screwdriver wrapped in protective tape to remove it. Take care not to damage the O-ring seat section.

-

- Assemble the fuel tank unit.

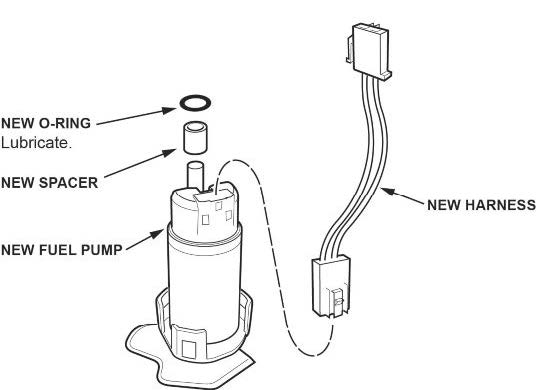

16.1 Install the new spacer, O-ring, and wire harness to the new fuel pump.

NOTES

- The O-ring must be installed on the pump as shown, not on the fuel filter side.

- Coat the O-ring with clean engine oil; do not use any other oil or fluid.

- Do not pinch the O-ring during installation.

- When connecting the wire harness, make sure the connection is secure and the connectors are firmly locked into place.

- Use all the new parts supplied in each replacement kit.

16.2 Place the fuel pump on a bench, then install the filter to the fuel pump.

16.3 Install the fuel filter assembly to the reservoir.

-

-

- Install a new O-ring on Joint A before connecting it.

- Coat the O-ring with clean engine oil; do not use any other oil or fluid.

- Do not pinch the O-ring during installation.

- Insert the spring to the sliding shaft and make sure it is aligned when installing the fuel filter.

-

NOTES

- Make sure the fuel tube is routed exactly as shown in the photo taken before disassembly.

- Make sure the three release clips are fully engaged.

16.4 Connect joint B.

16.5 Install the new E-rings.

NOTE

After installation, make sure the E-rings can be rotated with your finger. If they cannot be rotated, the E-rings may not be fully seated or may be incorrectly installed.

16.6 Install the fuel level sensor to the reservoir. Make sure the lock is engaged.

NOTE

When installing the fuel level sensor, make sure the connection is secure and the connector is firmly locked into place. Be careful not to bend or twist it excessively.

16.7 Install the wiring harness to the clamps.

NOTES

- Clip in the smaller harness wires followed by the larger wires.

- Make sure not to damage the wire harness.

- Make sure the wire harness is routed exactly as shown in the picture taken before disassembly.

- Do not spread the clamps too wide. Spreading them too wide may damage them.

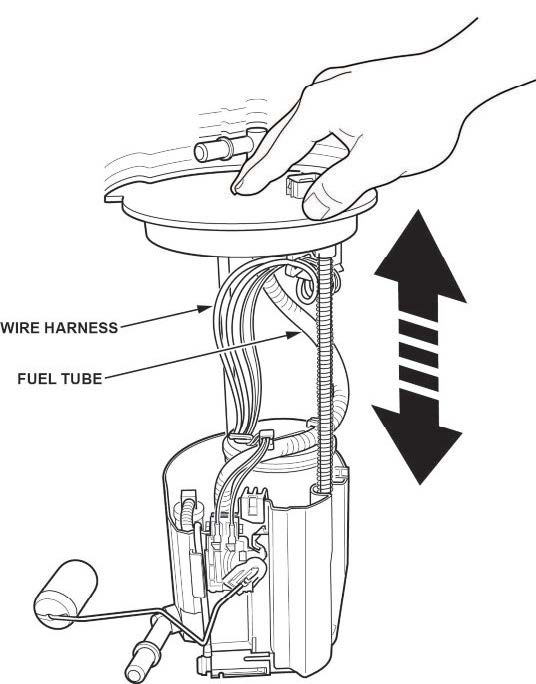

16.8 While compressing the fuel tank unit, make sure the movement is smooth and the fuel tube and wiring harness do not pinch or bind.

-

-

- Make sure the wire harness is not stretched.

- Make sure the fuel tube is not pinched.

-

- Install a new O-ring onto the fuel tank unit.

NOTES

- Be careful not to damage the new O-ring.

- Do not coat the O-ring with any oil.

- Install the new retainer to the transfer tube and partially install the fuel tank unit as necessary to connect it.

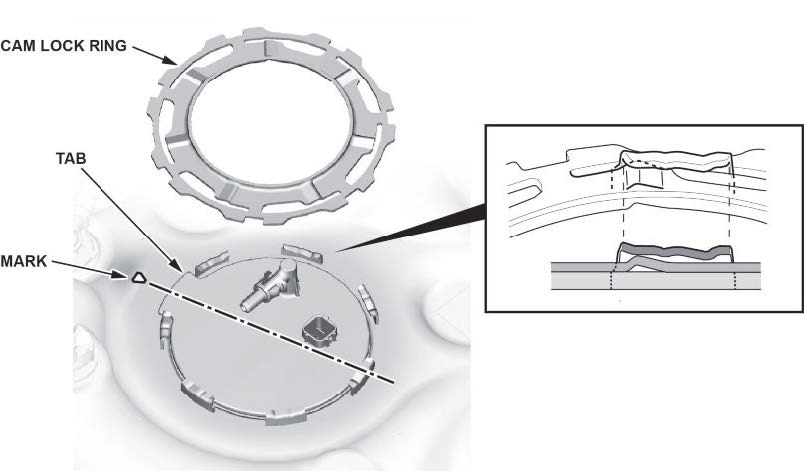

- Line up the tab of the fuel tank unit as shown, and temporarily insert the new fuel tank unit cam lock ring.

NOTICE

If the cam lock ring is not properly installed, the fuel tank can be damaged and will require replacement.

NOTE

Make sure the fuel tank unit cam lock ring is seated correctly on the fuel tank unit with all tabs fully engaged.

- Turn the fuel tank unit cam lock ring clockwise using the fuel sender wrench.

NOTES

- Make sure the fuel sender wrench is not floating.

- Securely set the fuel tank positioning edge to the tab of the fuel tank unit cam lock ring.

- Make sure the fuel tank unit cam lock ring is seated correctly on the fuel tank unit with all tabs fully engaged.

- Install the new retainer to the quick-connecting fitting.

- Connect the fuel tank connector and the quick-connecting fitting.

- Check for fuel leaks.

23.1 Turn the ignition to ON, but do not turn the engine on. After the fuel pump runs for about 2 seconds, the fuelline will be pressurized. Repeat this two or three times, then make sure there is no fuel leakage.

- Install the fuel tank unit access panel.

- Install the remaining parts in the reverse order of removal.

- Clear all DTCs using an i-HDS.

- Do the VSA Sensor Neutral Position Memorization procedure.

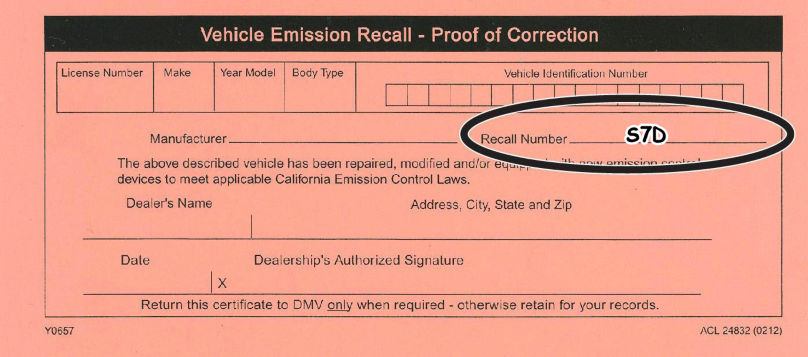

- California residents only: Fill out a Vehicle Emissions Recall – Proof of Correction certificate, and use S7D as the recall number. Have the service advisor give the certificate to your customer, and advise him or her to keep it as proof that the recall was completed. Your customer will need to submit this certificate to the DMV only if the DMV requests it. If you need more certificates, use reorder number Y0657.

END

July 2020

NHTSA Recall 20V-314

IMPORTANT SAFETY RECALL

This notice applies to your vehicle: XXXXXXXXXXXXXXXXX

Dear FIRSTNAME LASTNAME:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

WHAT IS THE REASON FOR THIS NOTICE?

Acura has decided that a defect which relates to motor vehicle safety exists in certain 2019 model year RDX vehicles that may have a fuel pump module with out of specification impellers. Over time, these impellers may absorb an excessive amount of fuel and deform. A deformed impeller may cause the fuel pump to stop working.

has decided that a defect which relates to motor vehicle safety exists in certain 2019 model year RDX vehicles that may have a fuel pump module with out of specification impellers. Over time, these impellers may absorb an excessive amount of fuel and deform. A deformed impeller may cause the fuel pump to stop working.

SAFETY CONSEQUENCE

An inoperative fuel pump could prevent an engine from starting or cause a vehicle to stall while being driven, increasing the risk of a crash.

EMISSION CONSEQUENCE

The check engine light may illuminate as a result of this defect. Your vehicle may fail a state or local emissions inspection when such tests are required under state law if you do not have the repair done.

WHAT WILL ACURA DO?

DO?

The dealer will replace the fuel pump assembly for free.

WHAT SHOULD YOU DO?

Please call any authorized Acura dealer and make an appointment to have your vehicle’s fuel pump assembly replaced for free. Once you make an appointment for your vehicle, be advised that the replacement process may take approximately 1 hour and 15 minutes. However, your dealer can provide you with a better estimate of the overall time for this service visit, as it may be necessary to make your vehicle available for a longer period of time. If you are not the only driver of this vehicle, please advise all other drivers and passengers of this important information.

dealer and make an appointment to have your vehicle’s fuel pump assembly replaced for free. Once you make an appointment for your vehicle, be advised that the replacement process may take approximately 1 hour and 15 minutes. However, your dealer can provide you with a better estimate of the overall time for this service visit, as it may be necessary to make your vehicle available for a longer period of time. If you are not the only driver of this vehicle, please advise all other drivers and passengers of this important information.

CHECK YOUR VEHICLE FOR OPEN RECALLS

You can check your vehicle’s eligibility for repair under this or any other recall. Please access the Acura Recall Lookup tool at www.recalls.acura.com and enter your Vehicle Identification Number (VIN).

Recall Lookup tool at www.recalls.acura.com and enter your Vehicle Identification Number (VIN).

CALIFORNIA OWNERS ONLY

The DMV will not renew your vehicle’s registration until this emissions recall has been completed. After completing the repair procedure, your dealer will give you a Vehicle Emission Recall – Proof of Correction certificate. Please make sure the dealer completes and provides you the certificate. Keep the certificate for your records as proof that the emissions recall was completed. Submit the certificate to the DMV only if the DMV requests it.

EMISSION WARRANTY

In order to ensure your full protection under the emission warranty provisions, it is recommended that you have your vehicle repaired as soon as possible. Failure to do so could be determined as lack of proper maintenance.

OWNER INFORMATION

You received this notice because government regulations require that notification be sent to the last known owner of record. Our records are based primarily on state registration and title information, which indicate that you are the current owner of this vehicle. If this is not the case, or if any of the information is not correct, please complete, sign and return the Information Change Card and we will then update our records. If you are a lessor of this vehicle, federal regulations require you to forward this notice to your lessee within ten days.

DO YOU STILL HAVE MORE QUESTIONS?

If you have questions or concerns, we encourage you to:

- contact your local Acura

dealer; or

dealer; or - call American Honda

’s Customer Support & Campaign Center at 1-888-234-2138 Monday through Friday, 6:00 a.m. to 5:00 p.m., Pacific Time; or

’s Customer Support & Campaign Center at 1-888-234-2138 Monday through Friday, 6:00 a.m. to 5:00 p.m., Pacific Time; or - visit Twitter @AcuraClientCare; or

- visit recalls.acura.com to use “Ask Us”, our 24/7 virtual agent.

If you believe that American Honda or the dealer has failed or is unable to remedy the defect in your vehicle, without charge and within a reasonable period of time (60 days from the date you first contact the dealer for a repair appointment), you may submit a complaint to the Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590.

or the dealer has failed or is unable to remedy the defect in your vehicle, without charge and within a reasonable period of time (60 days from the date you first contact the dealer for a repair appointment), you may submit a complaint to the Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590.

Alternatively, you may call the NHTSA toll-free Safety Hotline at 888-327-4236 (TTY 800-424-9153), or go to https://www.safercar.gov. We apologize for any inconvenience this recall may cause you.

Sincerely,

American Honda Motor Co., Inc.

Motor Co., Inc.

Campaign #S7D / Service Bulletin #20-026

Julio del 2020

Campaña de seguridad NHTSA 20V-314

CAMPANA DE SEGURIDAD IMPORTANTE

Esta notificación aplica a su vehículo: XXXXXXXXXXXXXXXXX

Estimado FIRSTNAME LASTNAME:

Esta notificación ha sido enviada a usted de acuerdo con el decreto de la oficina de Administración Nacional de Seguridad del Tráfico en las Carreteras (National Highway Traffic Safety Administration o NHTSA por sus siglas en inglés).

¿CUÁL ES EL MOTIVO DE ESTA NOTIFICACIÓN?

Acura ha determinado que existe un defecto el cual está relacionado con la seguridad del vehículo en algunos vehículos modelo RDX año modelo 2019 que pueden tener un módulo de la bomba de combustible con impulsores fuera de especificación. Con el paso del tiempo, estos impulsores pueden absorber una cantidad excesiva de combustible y deformarse. Un impulsor deformado puede ocasionar que la bomba de combustible deje de funcionar.

ha determinado que existe un defecto el cual está relacionado con la seguridad del vehículo en algunos vehículos modelo RDX año modelo 2019 que pueden tener un módulo de la bomba de combustible con impulsores fuera de especificación. Con el paso del tiempo, estos impulsores pueden absorber una cantidad excesiva de combustible y deformarse. Un impulsor deformado puede ocasionar que la bomba de combustible deje de funcionar.

CONSECUENCIA DE SEGURIDAD

Una bomba de combustible inoperativa puede prevenir que un motor no arranque u ocasionar que un vehículo se detenga cuando es conducido, aumentando el riesgo de un choque.

CONSECUENCIA DE EMISIÓN

La luz indicadora de fallas (verificar el motor) puede iluminarse como resultado de este defecto. Su vehículo puede fallar una inspección de emisiones local o estatal cuando tales pruebas sean requeridas bajo la ley estatal si usted no completa la reparación.

¿QUÉ HARÁ ACURA ?

?

El concesionario reemplazará el conjunto de la bomba de combustible de forma gratuita.

¿QUÉ DEBE HACER USTED?

Por favor llame a cualquier concesionario autorizado Acura y haga una cita para el reemplazo del conjunto de la bomba de combustible del vehículo de forma gratuita. Una vez que programe una cita para su vehículo, le avisamos que el proceso de reemplazo puede tardar aproximadamente 1 hora y 15 minutos. No obstante, su concesionario le puede ofrecer un mejor estimado del tiempo total de esta visita de servicio, ya que pudiera ser necesario que su vehículo esté disponible por un periodo más largo. Si usted no es el único conductor de este vehículo, por favor informe a todos los conductores y pasajeros sobre esta información importante.

y haga una cita para el reemplazo del conjunto de la bomba de combustible del vehículo de forma gratuita. Una vez que programe una cita para su vehículo, le avisamos que el proceso de reemplazo puede tardar aproximadamente 1 hora y 15 minutos. No obstante, su concesionario le puede ofrecer un mejor estimado del tiempo total de esta visita de servicio, ya que pudiera ser necesario que su vehículo esté disponible por un periodo más largo. Si usted no es el único conductor de este vehículo, por favor informe a todos los conductores y pasajeros sobre esta información importante.

VERIFIQUE SI SU VEHÍCULO TIENE UNA CAMPAÑA DE SEGURIDAD PENDIENTE

Puede verificar la elegibilidad de su vehículo para que sea reparado bajo esta campaña de seguridad o bajo cualquier otra. Por favor acceda la herramienta “Acura Recall Lookup” en www.recalls.acura.com e ingrese su número de identificación del vehículo (VIN).

Recall Lookup” en www.recalls.acura.com e ingrese su número de identificación del vehículo (VIN).

SOLAMENTE PROPIETARIOS EN CALIFORNIA

El DMV no renovará su registro del vehículo hasta que esta campaña de seguridad de emisiones haya sido completada. Después de completar este procedimiento de reparación, su concesionario le entregará un certificado de Prueba de Corrección – Campaña de seguridad de emisiones del vehículo (Vehicle Emissions Recall – Proof of Correction). Por favor asegúrese que el concesionario complete y le otorgue el certificado. Mantenga el certificado para sus registros como prueba que la campaña de emisiones fue completada. Envíe el certificado para el DMV solamente si el DMV lo solicita.

GARANTÍA DE EMISIONES

A fin de garantizar su protección completa bajo las disposiciones con respecto a la garantía de emisiones, se recomienda que haga que su vehículo sea reparado tan pronto sea posible. De no hacerlo podría determinarse como una falta de mantenimiento adecuado.

INFORMACIÓN DEL PROPIETARIO

Usted recibió esta notificación porque las regulaciones gubernamentales requieren que esta notificación sea enviada al último propietario registrado. Nuestros registros están basados principalmente en la información del título y registro en el estado, el cual indica que usted es el propietario actual de este vehículo. Si no es el caso o si la información no está correcta, por favor complete, firme y devuelva la tarjeta de Cambio de información anexa y nosotros actualizaremos nuestros registros. Si usted es el arrendador de este vehículo, las regulaciones federales requieren que usted envié una copia de esta notificación a su arrendatario en un lapso de diez días.

¿USTED TODAVÍA TIENE MÁS PREGUNTAS?

Si usted tiene preguntas o inquietudes, le recomendamos que:

- se comuníquese con su concesionario Acura

local; o

local; o - llame al Centro de Apoyo al Cliente y Campañas de American Honda

al 1-888-234-2138 de lunes a viernes, 6:00 a.m. a 5:00 p.m., hora del Pacífico; o

al 1-888-234-2138 de lunes a viernes, 6:00 a.m. a 5:00 p.m., hora del Pacífico; o - visite Twitter @AcuraClientCare; o

- visite recalls.acura.com

Si usted cree que American Honda o el concesionario ha fallado o no le es posible reparar el defecto en su vehículo, sin cobro alguno y dentro de un período de tiempo razonable (60 días desde la fecha en que usted contactó por primera vez el concesionario para la cita de la reparación), usted puede enviar una queja a: Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590. Alternativamente, usted también puede comunicarse con el número de llamada sin costo (Toll-free) Safety Hotline de NHTSA al 888-327-4236 (TTY 800-424-9153), o visitar la página web https://www.safercar.gov.

o el concesionario ha fallado o no le es posible reparar el defecto en su vehículo, sin cobro alguno y dentro de un período de tiempo razonable (60 días desde la fecha en que usted contactó por primera vez el concesionario para la cita de la reparación), usted puede enviar una queja a: Administrator, National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590. Alternativamente, usted también puede comunicarse con el número de llamada sin costo (Toll-free) Safety Hotline de NHTSA al 888-327-4236 (TTY 800-424-9153), o visitar la página web https://www.safercar.gov.

Le pedimos disculpas por cualquier inconveniente que esta campaña de seguridad pudiera causarle. Atentamente,

American Honda Motor Co., Inc.

Motor Co., Inc.

Campaña #S7D / Boletín de servicio #20-026

Remedy Instructions and TSB

RCRIT-20V314-3836.pdf 2022.538KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V314-9123.pdf 2102.638KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)- S7D – 2019 Acura RDX

RDX

RCONL-20V314-1996.pdf 190.875KB

Loading...

Loading...

Latest Recalls Documents

- Deep Cleans GDI (Gasoline Direct Injection) / PFI (Port Fuel Injection) Intake Valves, As Well As, The Throttle Body, Intake Ports, Fuel Injectors and Combustion Chambers

- Helps Restore Fuel Economy and Maximize Horse Power

- Removing Carbon and Fuel Deposits From Gasoline Engines Intake Valves, Intake Ports and Turbos Is Essential to Ensuring Optimal Vehicle Performance.

- Made with Carbon Clear and Trade, the Most Advanced P.E.A. Cleaning Agent Available

- Strong Enough to Cut Through Thick Carbon Deposits, Even at Extreme Engine Temperatures

- Comes with a dispenser hose and color-coded dials for easy use

- Removes hardened carbon deposits that can be harmful to your engine

- Auto cleaner helps to improve horsepower, fuel efficiency, engine life and acceleration

- Professional-grade car care for easy intake valve cleaning at home

- Formulated for Use In All Fuel-Injected Gasoline Engines, Including GDI

- Contains Polyetheramine (“PEA”) to Dissolve Carbon Buildup in Combustion Chambers

- Cleans ALL Types of Intake Valves, Including Those Found in PFI, TBI, and GDI Engines

- Safe On Catalytic Converters and Oxygen Sensors

- Not For Use In Diesel Engines

- Increases power output

- Restores fuel efficiency

- Restores performance

- BG Platinum Air Intake, Valve & Combustion Chamber Cleaner is a diverse blend of cleaning ingredients that break through the nearly impenetrable deposit exterior and deliver potent detergents to the vulnerable center

- Restores MPG

- Restores engine performance

- Restores power

- Reduces harmful emissions

- Requires pressurized tool

- One New Aftermarket Replacement Turbo Ii Pre-Cleaner For Model 46 (With 4.5" Inlet) That Features Ev

- OEM Numbers Are Provided for Reference Only. Please Verify Fit Prior To Ordering.

- Please Note: Some Listings Use Stock Images for Reference and May Differ from the Actual Product.

- This Aftermarket Part Is Made to Meet or Exceed Manufacturer (OEM) Specifications.

- Air Filter Cold Air Intake Filter Breather 12mm

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.