| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18V777

Manufacturer Honda (American Honda Motor Co.)

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 64,785

Coating on Rear Brake Caliper Pistons/FMVSS 135

A reduction of braking performance increases the risk of a crash.

Summary

Honda (American Honda Motor Co.) is recalling certain 2017-2019 Acura MDX, 2017-2018 Acura MDX Sport Hybrid, 2018-2019 Honda HR-V and Honda Odyssey, and 2016 Honda HR-V vehicles. The rear brake caliper pistons may have an insufficient coating, causing gas pockets to form, reducing brake performance. As such, these vehicles fail to comply with the requirements of Federal Motor Vehicle Safety Standard (FMVSS) number 135, “Light Vehicle Brake Systems.”

Remedy

Owners will be notified, and Honda or Acura dealers will bleed the brakes, free of charge. The recall is expected to begin December 17, 2018. Owners may contact Honda customer service at 1-888-234-2138. Honda’s numbers for this recall are C31 and L30.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Honda has a Recall

B18-061

November 2, 2018

Version 1

Safety Recall: Soft or Low Brake Pedal

AFFECTED VEHICLES

| Year | Model | Trim | VIN Range |

| 2017-19 | MDX | ALL | Check the iN VIN status for eligibility. |

| 2017-18 | MDX Sport Hybrid | ALL | Check the iN VIN status for eligibility. |

BACKGROUND

The brake pedal may have a soft feeling or travel to the floor with low effort because of air bubbles in the brake fluid. Air may be trapped in the system due to the temporary release of air bubbles from improperly plated rear brake caliper pistons. This may cause low braking performance or increased pedal stroke, increasing the risk of a crash.

CLIENT NOTIFICATION

Owners of affected vehicles will be sent a notification of this campaign.

Do an iN VIN status inquiry to make sure the vehicle is shown as eligible.

Some vehicles affected by this campaign may be in your new or used vehicle inventory.

Failure to repair a vehicle subject to a recall or campaign may subject your dealership to claims or lawsuits from the client or anyone else harmed as a result of such failure. To see if a vehicle in inventory is affected by this safety recall, do a VIN status inquiry before selling it.

CORRECTIVE ACTION

Bleed the brake system.

NOTE

The MDX and MDX Sport Hybrid require different repair procedures.

MDX Sport Hybrid REPAIR PROCEDURE – Page 7

REQUIRED MATERIALS

| Part Name | Part Number | Quantity |

| Brake Fluid (DOT 3) | 08798-9008A | 2 |

WARRANTY CLAIM INFORMATION

| Operation Number | Description | Flat Rate Time | Defect Code | Symptom Code | Template ID | Failed Part Number |

| 4130A9 | MDX (Non-Sport

Hybrid) – Bleed the brake system. (Includes rear caliper bleed procedure.) |

1.6 hrs | 6RB00 | L3000 | B18061A | 43018-TZ5-A11 |

| 4130A2 | MDX Sport Hybrid Bleed the brake system. (Includes rear caliper bleed procedure.) | 1.8 hrs | 6RB00 | L3000 | B18061B | 43018-TZ5-A11 |

Skill Level: Repair Technician

REPAIR PROCEDURE – MDX (NON SPORT HYBRID)

NORMAL BLEED

NOTICE

Do not spill brake fluid on the vehicle, it may damage the paint. If brake fluid does contact the paint, wash it off immediately with water.

NOTES

- Review the Service Precautions before doing repairs or service.

- Before beginning the bleeding procedure, remove the reservoir cap and strainer, and remove any dirt and debris then reinstall the strainer only.

- Use only new Acura DOT 3 Brake Fluid from an unopened container. Using a non-Acura brake fluid can cause corrosion and shorten the life of the system. Do not reuse the drained brake fluid.

- The brake fluid in the reservoir connected to the master cylinder must be at the MAX (upper) level mark at the start of the bleeding procedure and checked after bleeding each wheel. Add fluid as required.

- Unless indicated, the illustrations shown are examples only and may not match your vehicle.

Bleed the brake system in this order:

- Front Driver’s Side Brake Caliper

- Front Passenger’s Side Brake Caliper

- Rear Passenger’s Side Brake Caliper

- Rear Driver’s Side Brake Caliper

- Raise the vehicle on a lift.

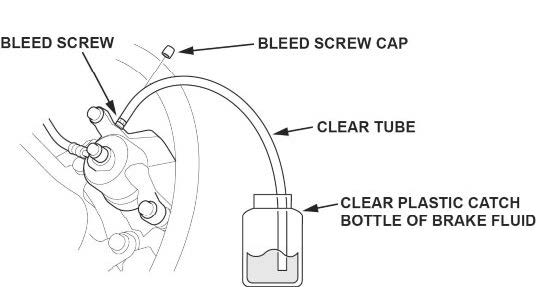

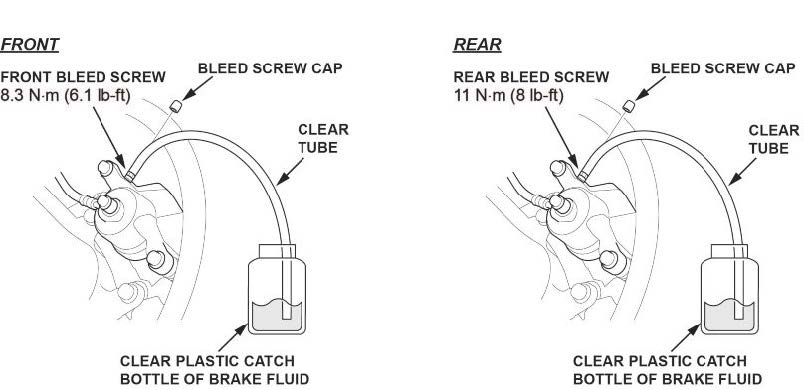

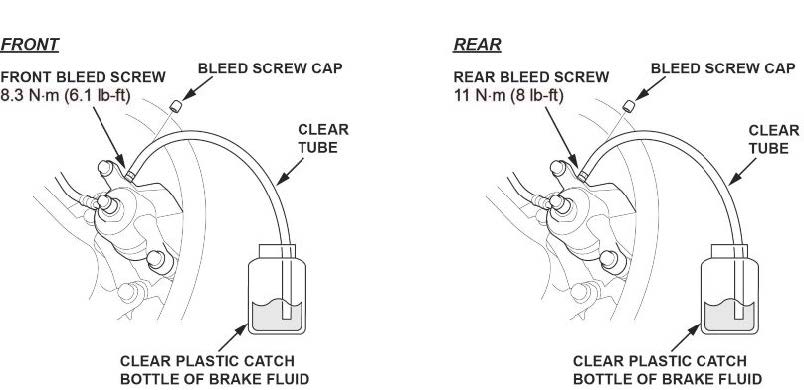

- Attach a clear tube to the bleed screw.

- Submerge the other end of the clear tube into a clear plastic catch bottle of brake fluid.

- Have an assistant slowly pump the brake pedal several times then apply steady continuous pressure.

- Loosen the bleed screw slowly to bleed the fluid into the plastic catch bottle. The brake pedal will travel toward the floor as the fluid is bled from the system.

- When the brake pedal reaches the floor, have the assistant hold the pedal in that position, then tighten the bleed screw to the specified torque. The brake pedal can now be released.

NOTE

Inspect the brake lines and fittings for damage, leaks, deterioration, or twisting.

| Component | Specified Torque Value |

| Front Brake Caliper Bleed Screw | 8.3 N·m (6.1 lbf-ft ) |

| Rear Brake Caliper Bleed Screw | 11 N·m (8 lbf-ft) |

- Repeat steps 3 thru 6 until the brake fluid in the clear tube appears fresh and there are no air bubbles in the fluid.

- Repeat this procedure for each caliper in the bleeding sequence.

- Go to REAR CALIPER BLEED.

REAR CALIPER BLEED

NOTE

Do the following procedure only after doing the NORMAL BLEED procedure.

Bleed the rear brakes in this order:

- Passenger’s Side Rear Brake Caliper

- Driver’s Side Rear Brake Caliper

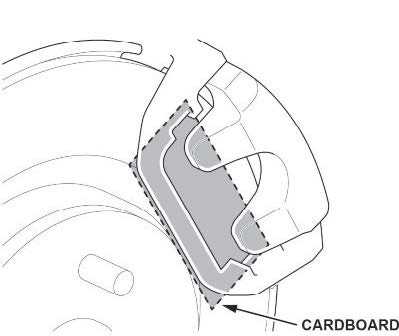

- Remove the passenger’s side rear caliper body and remove the outer pad.

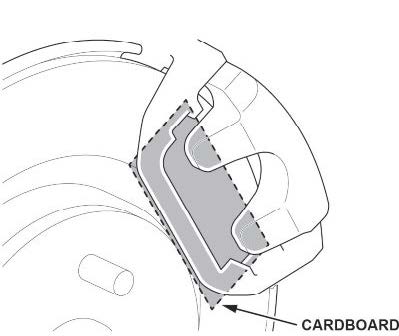

- Place a small piece of cardboard in place of the outer pad and reinstall the brake caliper.

- Slowly press the brake pedal until the caliper body contacts the cardboard.

- Turn the ignition to ON.

- Apply and release the parking brake.

NOTE

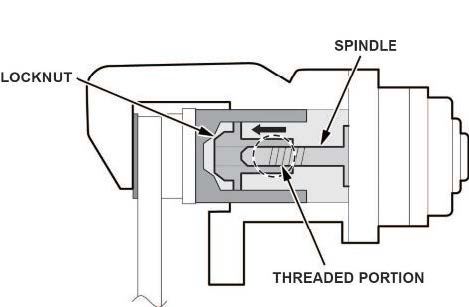

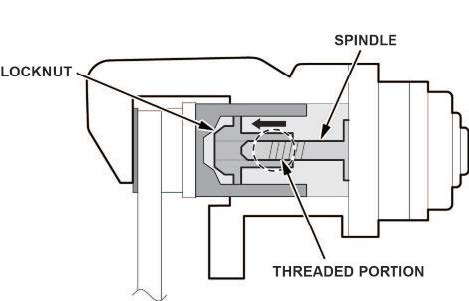

The air in the threaded portion between the spindle and the locknut is discharged by operating the parking brake.

- Connect the HDS to the data link connector (DLC).

- Select ELECTRIC PARKING BRAKE from the BRAKE SYSTEM menu with the HDS, then select BRAKE PAD MAINTENANCE MODE from ADJUSTMENT, and follow the screen prompts.

NOTE

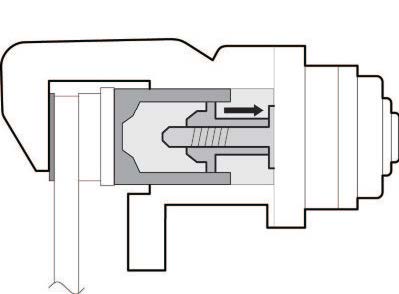

The spindle returns to the initial position by entering the brake pad maintenance mode.

- Turn the ignition to OFF.

- Disconnect the negative cable from the 12 volt battery.

- Press the brake pedal several times.

- Disconnect the electric parking brake actuator connector, and remove the caliper body without disconnecting the brake hose from the caliper body.

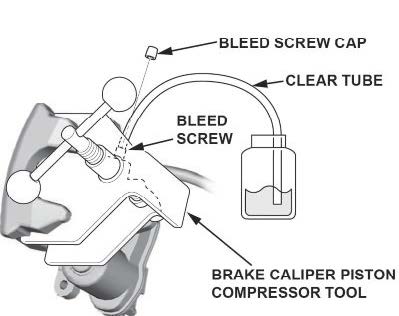

- Hold the caliper body so that the bleed screw is upright.

- Direct any air trapped in the caliper by doing the following.

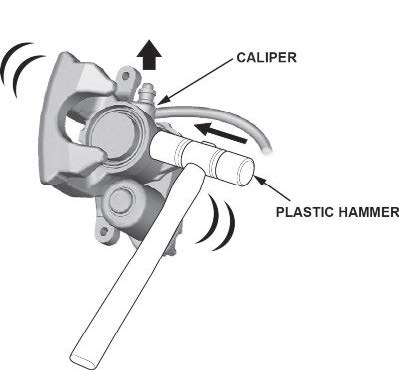

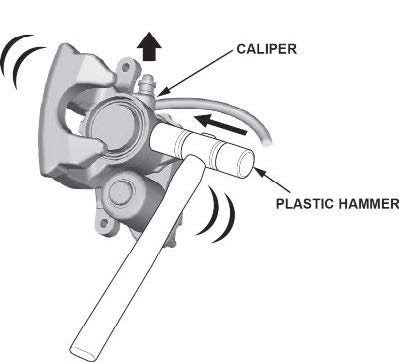

13.1 Shake the caliper side to side.

13.2Strike the caliper several times using a plastic hammer.

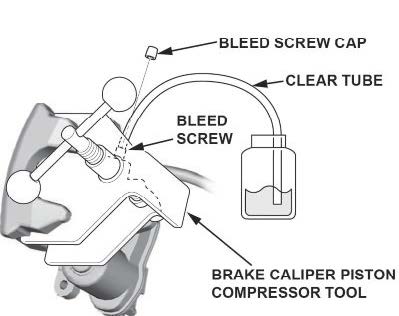

- Attach a clear tube to the bleed screw.

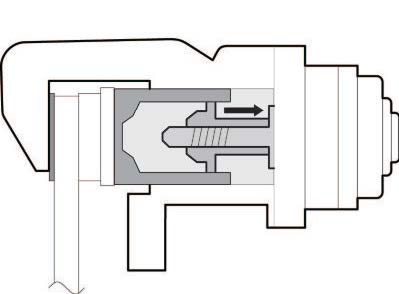

- Install a commercially available brake caliper piston compressor tool between the caliper body and piston.

- Loosen the bleed screw slowly and press in the piston with the brake caliper piston compressor tool.

- If there are air bubbles in the fluid, tighten the bleed screw to the specified torque, install the rear brake caliper and repeat steps 2 thru 16.

- If there are no air bubbles in the fluid, tighten the bleed screw to the specified torque, remove the cardboard and reinstall the outer pad and caliper.

| Component | Specified Torque Value |

| Rear Brake Caliper Bleed Screw | 11 N·m (8 lbf-ft) |

- Connect the electric parking brake actuator connector.

- Press the brake pedal several times.

- Reconnect the negative cable to the 12 volt battery.

- Turn the ignition to ON.

- Select ELECTRIC PARKING BRAKE from the BRAKE SYSTEM menu with the HDS, then select BRAKE PAD MAINTENANCE MODE from ADJUSTMENT, and follow the screen prompts.

- Apply and release the parking brake.

- Turn the ignition to OFF.

- Repeat this procedure for the rear caliper body on the opposite side.

REPAIR PROCEDURE MDX SPORT HYBRID

BRAKE SYSTEM – BLEED 1 (Between Pedal Feel Simulator and Brake Caliper)

NOTICE

Do not spill brake fluid on the vehicle, it may damage the paint. If brake fluid does contact the paint, wash it off immediately with water.

NOTES

- Review the Service Precautions before doing repairs or service.

- Before beginning the bleeding procedure, remove the reservoir cap and strainer, and remove any dirt and debris then reinstall the strainer only.

- Use only new Acura DOT 3 Brake Fluid from an unopened container. Using a non-Honda brake fluid can cause corrosion and shorten the life of the system. Do not reuse the drained brake fluid.

- The brake fluid in the reservoir connected to the master cylinder must be at the MAX (upper) level mark at the start of the bleeding procedure and checked after bleeding each wheel. Add fluid as required.

- Unless indicated, the illustrations shown are examples only and may not match your vehicle.

Bleed the brake system in this order:

- Front Driver’s Side Brake Caliper

- Front Passenger’s Side Brake Caliper

- Rear Passenger’s Side Brake Caliper

- Rear Driver’s Side Brake Caliper

NOTE

Do not turn the ignition ON.

- Do the 12 volt battery terminal disconnection procedure.

- Remove the air cleaner.

- Attach a clear tube to the bleed screw.

- Submerge the other end of the clear tube into a clear plastic catch bottle of brake fluid.

- Have an assistant slowly pump the brake pedal several times then apply steady continuous pressure.

- Loosen the bleed screw slowly to bleed the fluid into the plastic catch bottle. The brake pedal will travel toward the floor as the fluid is bled from the system.

- When the brake pedal reaches the floor, have the assistant hold the pedal in that position, then tighten the bleed screw to the specified torque. The brake pedal can now be released.

NOTE

Inspect the brake lines and fittings for damage, leaks, deterioration, or twisting.

| Component | Specified Torque Value |

| Front Brake Caliper Bleed Screw | 8.3 N·m (6.1 lbf-ft) |

| Rear Brake Caliper Bleed Screw | 11 N·m (8 lbf-ft) |

- Repeat steps 7 thru 9 until the brake fluid in the clear tube appears fresh and there are no air bubbles in the fluid.

- Repeat this procedure for each caliper in the bleeding sequence.

- Go to BRAKE SYSTEM – BLEED 2.

BRAKE SYSTEM – BLEED 2 (Between Pedal Feel Simulator and Tandem Motor Cylinder)

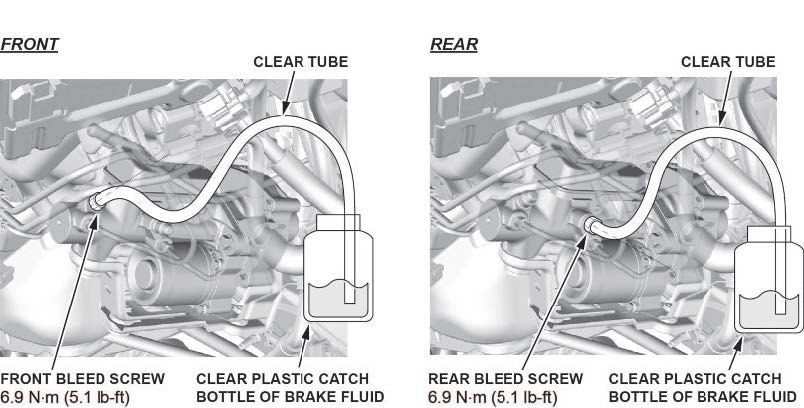

- Attach a clear tube to the front or rear tandem motor bleed screw.

- Submerge the other end of the clear tube into a clear plastic catch bottle of brake fluid.

- Have an assistant slowly pump the brake pedal several times then apply steady continuous pressure.

- Loosen the bleed screw slowly to bleed the fluid into the plastic catch bottle. The brake pedal will travel toward the floor as the fluid is bled from the system.

- When the brake pedal reaches the floor, have the assistant hold the pedal in that position, then tighten the bleed screw to the specified torque. The brake pedal can now be released.

| Component | Specified Torque Value |

| Front and Rear Bleed Screw | 6.9 N·m (5.1 lbf-ft) |

- Repeat steps 3 thru 5 until the brake fluid in the clear tube appears fresh and there are no air bubbles in the fluid.

- Repeat this procedure for the remaining tandem motor bleed screw.

- Reconnect the 12 volt battery.

- Install the air cleaner.

- Go to BRAKE SYSTEM – BLEED 3.

BRAKE SYSTEM – BLEED 3 (Between Pedal Feel Simulator and Brake Caliper)

Bleed the brake system in this order:

- Front Driver’s Side Brake Caliper

- Front Passenger’s Side Brake Caliper

- Rear Passenger’s Side Brake Caliper

- Rear Driver’s Side Brake Caliper

- Attach a clear tube to the bleed screw.

- Submerge the other end of the clear tube into a clear plastic catch bottle of brake fluid.

- Have an assistant slowly pump the brake pedal several times then apply steady continuous pressure.

- Loosen the bleed screw slowly to bleed the fluid into the plastic catch bottle. The brake pedal will travel toward the floor as the fluid is bled from the system.

- When the brake pedal reaches the floor, have the assistant hold the pedal in that position, then tighten the bleed screw to the specified torque. The brake pedal can now be released.

| Component | Specified Torque Value |

| Front Brake Caliper Bleed Screw | 8.3 N·m (6.1 lbf-ft) |

| Rear Brake Caliper Bleed Screw | 11 N·m (8 lbf-ft) |

- Repeat steps 3 thru 5 until the brake fluid in the clear tube appears fresh and there are no air bubbles in the fluid.

- Repeat this procedure for each bleed screw of the brake caliper in the bleeding sequence.

- Go to REAR CALIPER BLEED.

REAR CALIPER BLEED

NOTE

Do the following procedure only after doing the previously listed BLEED procedures.

Bleed the rear brakes in this order:

- Passenger’s Side Rear Brake Caliper

- Driver’s Side Rear Brake Caliper

- Remove the passenger’s side rear caliper body and remove the outer pad.

- Place a small piece of cardboard in place of the outer pad and reinstall the brake caliper.

- Slowly press the brake pedal until the caliper body contacts the cardboard.

- Turn the ignition to ON.

- Apply and release the parking brake.

NOTE

The air in the threaded portion between the spindle and the locknut is discharged by operating the parking brake.

- Connect the HDS to the data link connector (DLC).

- Select ELECTRIC PARKING BRAKE from the BRAKE SYSTEM menu with the HDS, then select BRAKE PAD MAINTENANCE MODE from ADJUSTMENT, and follow the screen prompts.

NOTE

The spindle returns to the initial position by entering the brake pad maintenance mode.

- Turn the ignition to OFF.

- Disconnect the negative cable from the 12 volt battery.

- Press the brake pedal several times.

- Disconnect the electric parking brake actuator connector and remove the caliper body without disconnecting the brake hose from the caliper body.

- Hold the caliper body so that the bleed screw is upright.

- Direct any air trapped in the caliper by doing the following.

13.1 Shake the caliper side to side.

13.2 Strike the caliper several times using a plastic hammer.

- Attach a clear tube to the bleed screw.

- Install a commercially available brake caliper piston compressor tool on the caliper body.

- Loosen the bleed screw slowly and press in the piston with the brake caliper piston compressor tool.

- If there are air bubbles in the fluid, tighten the bleed screw to the specified torque, install the rear brake caliper and repeat steps 2 thru 16.

- If there are no air bubbles in the fluid, tighten the bleed screw to the specified torque, remove the cardboard and reinstall the outer pad and caliper.

| Component | Specified Torque Value |

| Rear Brake Caliper Bleed Screw | 11 N·m (8 lbf-ft) |

- Connect the electric parking brake actuator connector.

- Press the brake pedal several times.

- Reconnect the negative cable to the 12 volt battery.

- Turn the ignition to ON.

- Select ELECTRIC PARKING BRAKE from the BRAKE SYSTEM menu with the HDS, then select BRAKE PAD MAINTENANCE MODE from ADJUSTMENT, and follow the screen prompts.

- Apply and release the parking brake.

- Turn the ignition to OFF.

- Repeat this procedure for the rear caliper body on the opposite side.

END

B18-061

November 2, 2018

Version 1

https://static.nhtsa.gov/odi/rcl/2018/RCRIT-18V777-3738.pdf

Loading...

Loading...

Manufacturer Notice

November 2, 2018

https://static.nhtsa.gov/odi/rcl/2018/RCMN-18V777-9691.pdf

Loading...

Loading...

DEFECT INFORMATION REPORT

https://static.nhtsa.gov/odi/rcl/2018/RMISC-18V777-7514.pdf

Loading...

Loading...

Recall Acknowledgement

November 15, 2018

https://static.nhtsa.gov/odi/rcl/2018/RCAK-18V777-7554.pdf

Loading...

Loading...

Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=18V777&docType=RCL

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100% longer than DOT 3, 50% longer than DOT 4, and 10% longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- Premium DOT 3 Brake Fluid has a minimum boiling point of 450°F

- Meets and exceeds DOT 3 and all other Federal and SAE specifications and standards for motor vehicle brake fluids

- Mixes with all DOT 3 approved brake fluids

- Designed for use in disc, drum and ABS brake systems

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

- Minimal decrease of boiling point due to excellent water locking properties

- Non-foaming when filling and bleeding the brake system

- Excellent corrosion protection due to selected additives

- High safety tolerance against steam bubbles

- Makes brake fluid changing intervals of up to 3 years possible

- Maintains proper movement for safe, effective stopping performance

- Helps deliver a quieter braking system

- Produces smoother pedal travel

- Provides longer brake life and performance

- Install Wagner with total confidence

Last update on 2024-04-24 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.