| “This site contains affiliate links for which OEMDTC may be compensated” |

A11-039

September 2, 2011

Applies To: 2005–10 Odyssey – Check the iN VIN status for eligibility

Warranty Extension: Steering Wheel Is Hard to Turn at Low Speeds

(Supersedes 11-039, dated August 20, 2011, to revise the information marked by the black bars)

(Replaces 10-076, Steering Wheel Is Hard to Turn Quickly at Low Speeds, dated July 15, 2011)

REVISION SUMMARY

In Applies To, the model year range was changed.

BACKGROUND

On some 2005–10 Odysseys, the power steering pump does not provide the intended amount of assistance while the vehicle is driven at slow speeds with low engine RPM, making the steering wheel hard to turn when driving in areas such as a parking lot. To increase customer confidence, American Honda is extending the warranty on the power steering pump in affected vehicles to 7 years from the original date of purchase or 100,000 miles, whichever comes first.

The warranty extension does not apply to any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded or similar title under any state’s law.

CUSTOMER NOTIFICATION

Owners of affected vehicles will receive a notification of this warranty extension. An example of the customer notification is included at the end of this service bulletin.

Before doing work on a vehicle, verify its eligibility by doing an iN VIN status inquiry.

CORRECTIVE ACTION

Do the diagnosis and, if needed, replace the power steering pump.

PARTS INFORMATION

| P/N | |

| Power Steering Pump Kit:

(Includes a power steering pump outlet hose O-ring and a power steering pump without the pulley or nut.) |

06561-RGL-305RM |

NOTE: You may receive P/N 56110-RGL-305RM, instead of 06561-RGL-305RM; the parts are the same.

REQUIRED MATERIALS

| P/N | |

| Honda Power Steering Fluid:

(One bottle repairs one vehicle) |

08206-9002 |

WARRANTY CLAIM INFORMATION

Operation Number: 5121G4

Flat Rate Time: 0.3 hour

Failed Part: P/N 56110-RGL-A02

Defect Code: 5P500

Symptom Code: R8100

Template ID: 11-039A

Skill Level: Repair Technician

DIAGNOSIS

- Make sure the tires are properly inflated. See the driver’s doorjamb label for more information.

- With the vehicle on the ground, start the engine, and warm it up to normal operating temperature (the radiator fan comes on).

- Warm up the power steering (P/S) fluid by letting the engine idle with the transmission in P, and turn the steering wheel from lock to lock about 20 times.

NOTE: If you do not heat up the P/S fluid, your diagnosis may not be correct.

- After the P/S fluid is warmed up, turn the steering wheel from lock to lock, and note the steering wheel effort.

- Continue turning the wheel from lock to lock, and raise the engine RPM to between 1,500 and 2,000. Note the steering wheel effort and compare it with the steering effort when the engine is idling.

- If the steering wheel is easier to turn at high RPM, go to REPAIR PROCEDURE.

- If the steering wheel effort at idle and high RPM is about the same, this bulletin does not apply. Compare your results against a known-good vehicle and continue with normal troubleshooting.

REPAIR PROCEDURE

NOTE:

- Do not drain the power steering fluid to replace the pump because the issue with the pump does not affect the fluid.

- Take care not to spill any P/S fluid on the vehicle body or other parts. Wipe off any spilled fluid immediately.

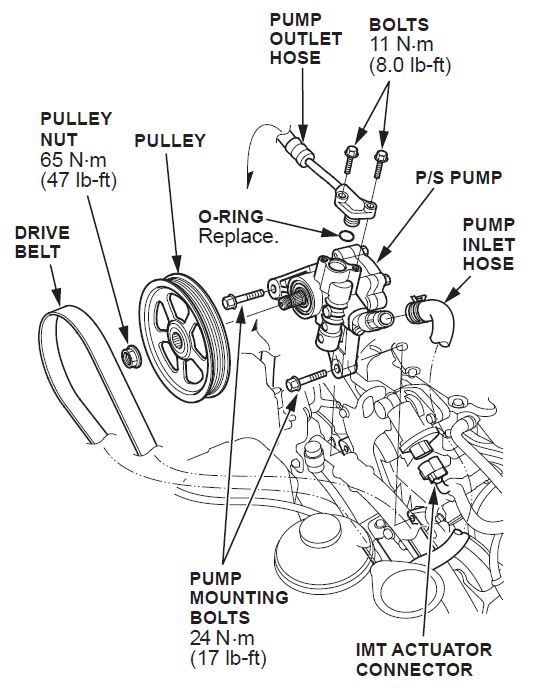

- Remove the engine cover.

- Disconnect the IMT actuator connector (if applicable).

- Remove the drive belt from the P/S pump pulley. Make sure no P/S fluid gets on the belt.

- Cover the auto-tensioner, the alternator, and the A/C compressor with shop towels to protect them from any spilled P/S fluid.

- Disconnect the inlet and outlet hoses from the P/S pump, and plug the open ends.

- Remove the pump mounting bolts and the pump.

- Hold the pump in a vise with soft jaws, then remove the pulley nut and pulley. Be careful not to damage the pump housing with the jaws of the vise.

- Install the pulley and the pulley nut on the new P/S pump. Torque the nut to 64 N.m (47 lb-ft).

- Install the pump to its bracket with the mounting bolts, then torque the bolts to 24 N.m (17 lb-ft).

- Connect the inlet hose to the pump.

- Place a new O-ring on the outlet hose, then connect the outlet hose to the pump, and torque it to 11 N.m (8 lb-ft).

- Reinstall the drive belt.

- Reconnect the IMT connector.

- Reinstall the engine cover.

- Make sure the P/S reservoir is filled to the upper line.

- Bleed the air from the P/S system:

- Start the engine, and with the vehicle in P, raise the engine speed to 2,000 RPM.

- Turn the steering wheel to the left until it stops. Hold it against the stop for 30 seconds.

- Turn the steering wheel to the right until it stops. Hold it against the stop for 30 seconds.

NOTE: If the pump is making a buzzing noise like in the sound file below, the pump is OK. There is still air trapped in the system. Repeat the air bleeding procedure.

- Recheck the reservoir to make sure it is filled to the upper line.

- Return the original pump for remanufacturing. Refer to Parts Information Bulletin A08-009, Remanufactured Steering Pump Program for packing and return instructions. To avoid a core charge, return the pump as instructed.

Example of Customer Letter

September 2011

Warranty Extension: Steering Wheel Is Hard to Turn at Low Speeds and Engine RPM Dear Odyssey Owner:

This letter is to notify you of a warranty extension on your Odyssey.

What is the reason for this notice?

On some 2005–10 Odysseys, the power steering pump may not provide the intended amount of assistance while the vehicle is driven at slow speeds with low engine RPM, making the steering wheel hard to turn when driving in areas such as a parking lot. To ensure your confidence in your vehicle, American Honda is extending the warranty on the power steering pump to 7 years from the original date of purchase or 100,000 miles, whichever comes first. This warranty extension provides coverage for the original owner and any subsequent owners. No action is required on your part unless you experience a problem. The warranty extension is valid except for any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded, or similar title under any state’s law.

What should you do?

If you believe your steering wheel is hard to turn at low speeds with low engine RPM, call any authorized Honda dealer and make an appointment to have your vehicle inspected. If the hard steering is related to the power steering pump not providing enough assistance, the power steering pump will be replaced at no cost. Please plan to leave your vehicle for half a day to allow the dealer flexibility in scheduling.

What to do if you feel this notice is in error.

Our records show that you are the current owner or lessee of a 2005–10 Odyssey involved in this warranty extension. If this is not the case, or the name/address information is not correct, please complete, sign, and return the enclosed, postage-paid Information Change Card. We will then update our records. If you previously paid to have the power steering pump replaced because of hard steering at low speeds with low engine RPM, you may be eligible for reimbursement, even if you no longer own the vehicle. Refer to the attached Instructions for Reimbursement form for eligibility requirements and the reimbursement procedure.

Lessor Information

If you are the vehicle lessor receiving this warranty extension notice, please forward a copy of this notice to the lessee within 10 days.

If you have questions

If you have any questions about this notice, or need assistance with locating a Honda dealer, please call Honda Automobile Customer Relations at 800-999-1009, and select option 4.

We apologize for any inconvenience this warranty extension may cause you.

Sincerely,

American Honda Motor Co., Inc.

Honda Automobile Division

Loading...

Loading...

NHTSA ID Number: 10036938

Manufacturer Communication Number: SB-10-076

Summary

HONDA: SEE DOCUMENT SEARCH BUTTON FOR OWNER LETTER. STEERING WHEEL IS HARD TO TURN QUICKLY AT LOW SPEEDS. WHEN TURNING WHEEL, QUICKLY, WHILE DRIVING AT LOW SPEEDS, IT IS HARD. ESPECIALLY WHILE DRIVING IN PARKING LOTS. THERE IS NOT ENOUGH ASSIST FROM THE POWER STEERING PUMP. STEERING PUMP NEEDS TO BE REPLACE. *PE UPDATED 7/29/11. *PE

2 Associated Documents

Customer Satisfaction Campaigns

CSC-10036938-4608.pdf 592.06KB

Loading...

Loading...

Customer Satisfaction Campaigns

CSC-10036938-7814.pdf 693.534KB

Loading...

Loading...

- High quality power steering fluid and conditioner

- Stops Noise

- Stops slipping

- Helps prevent unusual wear

- Protects seals

- Package Dimensions: 23.2 H x 6.9 L x 11.2 W (centimetres)

- Package Weight: 0.9 kilograms

- Country of Origin : United States

- Fit type: Universal

- The service solution for ALL European, North American, and Asian vehicles (Honda fluid recommended for Honda/Acura vehicles)

- Reduces friction and protects seals and hoses - extending the life of the power steering system

- Provides excellent cold and high temperature performance eliminating "morning sickness" stiffness

- Excellent for use in electric hydraulic systems

- Cleans and frees sticky turbines and pumps

- REDUCES NOISE AND SMOOTHES OUT HARD STEERING: A unique dual cavity bottle containing a combination of the best performance additives to repair the most common power steering fluid related problems.

- STOPS LEAKS AND RECONDITIONS RACK & PINION: Power Steering Repair can be used to top-off the existing fluid when low, or add a bottle when changing fluid.

- RESTORES PREFORMANCE: Works on all vehicles, domestic and import.

- ADDS PROTECTION: Compatible with ALL types of power steering fluid or ATF, including petroleum, mineral oil and synthetic formulas.

- For 2007 and up Honda and Acura vehicles, Backwards compatible with older Honda and Acura vehicles

- Lubricates and reduces wear in the pump, Prevents rust of the steel parts

- Lubricates and fights wear on the gear faces of the turning mechanism (eg. Rack and pinion)

- Protects and cleans the seals and hoses

- Contains no seal swellers

- Premium full-synthetic formulation specifically engineered for Asian vehicles

- Provides protection against wear, foaming, and corrosion to maintain optimal performance

- Designed for extreme temperatures while also providing excellent operation in low temperatures

- Delivers excellent oxidative stability for extended fluid life

- Engineered for Honda, Acura, Toyota, Lexus, and all other Asian-manufactured vehicles

- Helps prevent wear and corrosion

- Helps quiet annoying squeals and squeaks

- Smooths and eases steering operation

- Protects against wear and pump breakdown caused by abnormal wear, oxidation, and foaming

- Performs even in sub-zero temperatures

- Specifically designed for all power steering units

- For high and low mileage vehicles

- Use as needed, always consult your owner's manual for fluid specifications

- Stops Leaks

- Helps prevent wear and corrosion

- Improves vehicle longevity and performance

- Smooths and eases steering operation

- Helps prevent slippage

- 1 bottle treats 4 to 5 quarts of oil

- Stops and seals steering fluid leaks

- Works with all types of power steering leaks

- Part number: 1630

Last update on 2024-03-25 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

SEOCONTENT-START

CSC-10036938-4608 (U)H:ON”D.A. AUTOMOBILE DIVISION American Honda Motor Co., Inc. 1919 Torrance Blvd., – P.O. Box 2215 Torrance, CA 90509-9870 October 2011 Warranty Extension: Steerina Wheel Is Hard to Turn at I nlAt ~noo~~ ~nrf S::nnino DDIUI ~”‘ …. “”‘t'””””.;;11 ._. •• “” -·•~111-.i;. ,, •••• Dear Odyssey Owner: This letter is to notify you of a warranty extension on your Odyssey. What is the reason for this notice? On some 2007-2010 Odysseys, the power steering pump may not provide the intended amount of assistance while the vehicle is driven at slow speeds with low engine RPM, making the steering wheel hard to turn when driving in areas such as a parking lot. To ensure your confidence in your vehicle, American Honda is extending the warranty on the power steering pump to 7 years from the original date of purchase or 100,000 miles, whichever comes first. This warranty extension provides coverage for the original owner and any subsequent owners. No action is required on your part unless you experience a problem. The warranty extension is valid except for any vehicle that has ever been declared a total loss or sold for salvage by a financial institution or insurer, or has a branded, or similar title under any state’s law. What should you do? If you believe your steering wheel is hard to turn at low speeds with low engine RPM, call any authorized Honda dealer and make an appointment to have your vehicle inspected. If the hard steering is related to the power steering pump not providing enough assistance, the power steering pump will be replaced at no cost. Please plan to leave your vehicle for half a day to allow the dealer flexibility in scheduling. What to do if you feel this notice is in error. Our records show that you are the current owner or lessee of a 2007-2010 Odyssey involved in this warranty extension. If this is not the case, or the name/address information is not correct, please complete and sign the Information Change Card, and return it in the enclosed postage-paid envelope. We will then update our records. If you previously paid to have the power steering pump replaced because of hard steering at low c::n.::::::u::.rlc:: \Mith ln\A/ onnino RDl\11 \lf”\11 _,…,_._…,,,h., ” ” ” ‘ ” rY\ ‘ ! : :1\ / ho ol inihlo ff”\r r -oimh11t”c-o.mo.n+ o \ /an i f ‘””‘ 1 nn I”” ….. ,…”‘.- l””\u,n ♦hIVVT Vll~IIIV ‘ ” . . . . . , yvu I IIUJ t , J ‘ – , , \,.,ll~IU I \,,., IVI IVIIIIUU l..:>Vlll-c:;; 1 11., vvc;;-1111 yvu IIV IUl l~CI UVVll lllC vehicle. Refer to the attached Instructions for Reimbursement form for eligibility requirements and the reimbursement procedure. Lessor Information If you are the vehicle lessor receiving this warranty extension notice, please forward a copy of this notice to the lessee within 10 days. If you have questions If you have any questions about this notice, or need assistance with locating a Honda dealer, please call Honda Automobile Customer Relations at 800-999-1009, and select option 4. We apologize for any inconvenience this warranty extension may cause you. Sincerely, American Honda Motor Co., Inc. Honda Automobile Division 07HON080515 [V :H:O:ND.A. AUTOMOBILE DIVISION American Honda Motor Co., Inc. 1919 Torrance Blvd., – P.O. Box 2215 Torrance, CA 90509-9870 Octubre del 2011 Extension de garantia: El volante de la direcci6n se hace dificil de dar vuelta a bajas velocidades y revoluciones del motor Estimado propietario de un vehiculo Odyssey: Esta carta tiene la intencion de avisarle sabre una extension de la garantia de su Odyssey. lCual es el motivo de esta notificaci6n? En algunas Odyssey 2007-2010, la bomba de la servodireccion puede que no brinde la cantidad de asistencia deseada mientras se conduce el vehiculo a bajas velocidades con bajas revoluciones (RPM) del motor, hacienda dificil dar vueltas al volante la direccion cuando se maneja en aereas tales coma un estacionamiento. Para asegurar su confianza en su vehiculo, American Honda esta extendiendo la garantia en la bomba de la servodireccion a 7 arias de la fecha original de compra o 100.000 millas, lo que ocurra primero. Esta extension de garantia brinda cobertura al propietario original y a cualquier propietario subsiguiente. No se requiere ninguna accion de su parte a menos que usted experimente algun problema. La extension de garantia es valida excepto para cualquier vehiculo que se haya declarado como perdida total o vendido como chatarra por una institucion financiera o compania de seguro, o sabre el que se haya emitido un titulo de “mercancia averiada” o similar conforme a las !eyes de cualquier estado. l Que debe hacer? Si usted cree que es dificil dar vueltas al volante de la direccion a bajas velocidades con bajas RPM del motor, llame a cualquier concesionario Honda autorizado y programe una cita para que inspeccionen su vehiculo. Si lo diffcil al dar vueltas esta relacionado a la bomba de la servodireccion al no brindar suficiente asistencia, la bomba de la servodireccion sera reemplazada sin costo alguno. Par favor planifique dejar su vehiculo en el concesionario por media dia para permitir alga de flexibilidad en la programacion. Que debe hacer si considera que esta notificaci6n es err6nea Nuestros registros indican que usted es propietario o arrendador de un vehiculo Odyssey 2007-2010, el cual forma parte de esta extension de garantia. Si no es el caso, o si la informacion de nombre/direcci6n no es correcta, complete, firme y devuelva la Tarjeta de Cambia de lnformacion anexa, con el porte pagado. Con esto actualizaremos nuestros registros. Si usted previamente pago par el reemplazo de la bomba de la servodireccion debido a lo dificil de dar vueltas a bajas velocidades con bajas RPM del motor, usted puede recibir un reembolso, aunque usted no sea el propietario actualmente. Consulte las lnstrucciones para Reembolso que se encuentra anexa para los requisitos de elegibilidad y el procedimiento de reembolso. lnformaci6n para el arrendador Si usted es el arrendador del vehiculo que recibe esta notificacion de extension de garantia, por favor envie una copia de esta notificacion al arrendatario dentro de los siguientes 10 dias. Si t iene preguntas Si tiene preguntas acerca de esta notificacion o si necesita asistencia para ponerse en contacto con un concesionario Honda, por favor comuniquese con Atencion al Cliente de Automoviles Honda al 800-999-1009 y seleccione la opci6n 4. Le pedimos disculpas por cualquier inconveniente que esta extension de garantia pudiera causarle. Atentamente, American Honda Motor Co., Inc. Division Automotriz de Honda 07HON080515 (gJ :H:ON’D.A. Instructions for Reimbursement: 2007-2010 Odyssey Steering Wheel Is Hard To Turn at Low Speeds and Engine RPM Reimbursement eligibility You may be eligible for reimbursement if you previously paid to have your power steering pump replaced because of hard steering at low speeds with low engine RPM. • You must have had your vehicle repaired before receiving this notice. • You must have owned the vehicle at the time of repair. You are still eligible if you no longer own the vehicle. NOTE: Any incidental expense or inconvenience you may have suffered due to the loss of use of your vehicle may not be reimbursable. To apply for reimbursement ✓ Complete this reimbursement form. ✓ Attach a copy of the repair receipt or invoice for the repair. A copy of the repair invoice from an authorized Honda dealer or independent repair faci lity, indicating replacement of the power steering pump, will meet this need This invoice should show your vehicle’s model, vehicle identification number (VIN), the name and address of the facil ity that did the repair, the itemized cost of the repair (parts and labor), and the date the work was completed. ✓ Attach proof of payment, such as a copy of the cancelled check, bank statement, cash receipt, or credit card receipt showing that you paid for the repair. ✓ Mail this completed form and copies of the receipts and invoices to: American Honda Motor Co., Inc. Automobile Customer Service P.O. Box 2964 Torrance, CA 90509-2964 Please allow 6 to 8 weeks for reimbursement. Failure to include proper documentation can delay your reimbursement. If you have questions, please call your local authorized Honda dealer. If they cannot help you, call 800-999-1009, and select option 4. Fill in the following blanks. Please print clearly, and provide complete information. ( ) __________ _ Name Daytime telephone number Address Apt. No. City State Zip Code $ Vehicle Identification Number (VIN) REQUIRED Mileage at time of repair Total amount requested Name of facility that did the repair ______________ _________ ____ _ Make sure to include all required supporting information with your request. Note: Si usted necesita esta informaci6n en espaiiol por favor comuniquese con Servicio al Cliente al 800-999-1009 y seleccione la opci6n 4. 07HON080516 IMPORTANT: PRODUCT ADVISORY ENCLOSED PLEASE OPEN IMMEDIATELY PLEASE DELIVER TO REGISTERED OWNER VEHICLE IDENTIFICATION NUMBER R81 T PLEASE DETACH, SIGN BELOW AND PLACE IN RETURN ENVELOPE T —– ———— ———- ———————————————- – · INFORMATION CHANGE CARD PLEASE PROVIDE NAME AND ADDRESS CORRECTIONS ON THE REVERSE SIDE R81 I no longer own the Honda automobile. It was: O Sold (print name and address of new owner below, if known) 0 Exported 0 Destroyed 0 Stolen 0 Lease expired, vehicle returned. 0 Other: ◄ VEHICLE IDENTIFICATION NUMBER – —7 Nota: Si usted necesita esta informaci6n en espariol par favor comuniquese con Servicio al Cliente al 800-999-1009 y seleccione la opci6n 4. _ ____ J Signature: X Date:. _____ __ _ SIGNATURE OF REGISTERED OWNER OR LESSEE REQUIRED ~ PLEASE DETACH AND PLACE IN RETURN ENVELOPE ~ INFORMATION CHANGE CARD D My name or address has changed (Please update below) I I I I I I I I I I I ■~I ~I ~1~1~1~1~1~1~1~1~1~1~1~1- ~ LAST NAME FIRST NAME INITIAL 11111 1 11 1 ■ I I I 1 1 1 1 1 11 1 1 1 1 1 1 11 ■ 1 1 1 11 ADDRESS NUMBER STREET NAME ~ APARTMENT NO. I I I I I I I I I I I I I I I ■ I ■ I I I I 1-1 I I I I CITY STATE ZIP I I I I I I I I I I I I I I I I ■~l~l~l~-1~1~1~1~-l~l~l~l~I EMAIL ADDRESS PHONE

SEOCONTENT-END

Thank you so much. I just bought a used 2010 Odyssey and complained about this to the dealership. They just flushed the system and said it should be all good now, but it’s not. They never told me about this. I appreciate you making it known.